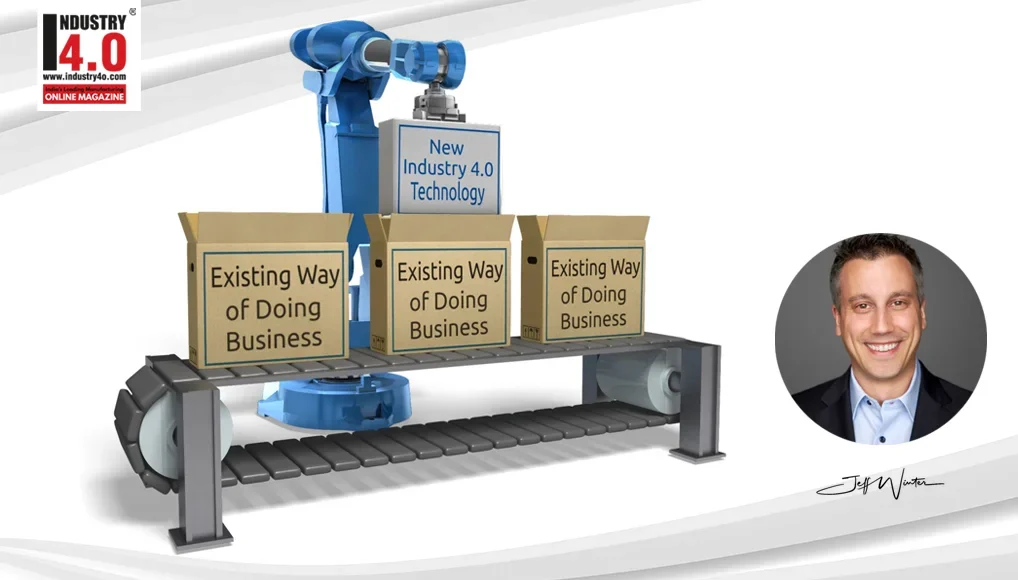

How to minimize your Industry 4.0 Investment

Are you tired of all those promises of digital transformation and technological advancement? Want to keep your Industry 4.0 investment as minimal as possible? Well, I’ve cracked the code! Here’s the sure-fire way to do it:

Attempt to deploy new Industry 4.0 technologies at scale without changing how your company operates.

Ta-da! It’s like magic – and it works every time!

Let’s dive into the secret recipe:

Ignore Data : Pretend data is just a buzzword. No need to capture or analyze it.

Resist Change : Keep your infrastructure, systems, and processes exactly the same. If it’s not broken, don’t fix it, right?

Cling to Old Roles : Don’t redefine roles and responsibilities. Change is scar

Maintain Mindsets : Encourage your employees to keep their traditional mindsets. New ways of thinking are overrated.

Avoid New Incentives : Don’t introduce new incentives for digital initiatives. The old ones work just fine.

Stick to Existing Models : Why experiment with new business models when the old ones have brought you this far?

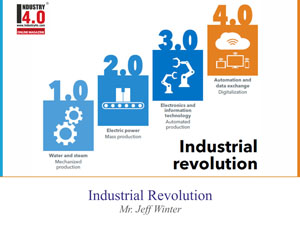

However, if you do decide to Implement Industry 4.0 the right way through full-scale Digital Transformation the results are impressive. According to McKinsey, the typical value captured by successfully implementing Industry 4.0:

- 15-20% Inventory-holding cost reduction

- 15-30% labor productivity increase

- 30-50% machine downtime reduction

- 10-30% throughput increase

- 85% forecasting accuracy improvement

- 10-20% cost-of-quality improvement.

Without this transformation, the value you can capture will be limited. So, if you’re serious about Industry 4.0, it’s time to embrace change and start your digital transformation journey.

Read more on the McKinsey Study:

Follow hashtagJeffWinterInsights to stay current on Industry 4.0 and other cool tech trends

About the Author :

Jeff Winter is an Industry 4.0 & Digital Transformation Enthusiast | Business Strategist | Avid Storyteller | Tech Geek | Public Speaker

Jeff Winter with over 15 years of experience working for different industrial automation product and solution providers, Jeff has a unique ability to simplify and communicate complex concepts to a wide range of audiences, educating and inspiring people from the shop floor up to the executive board room. As part of his experience, Jeff is also very active in the community of Industry 4.0.

Jeff is a part of the International Board of Directors for MESA (Manufacturing Enterprise Solutions Association), he is in the leadership committee for the Smart Manufacturing & IIoT Division of ISA (International Society of Automation), he is a U.S. registered expert for IEC (International Electrotechnical Commission) as a member of TC 65, and also part of Purdue University’s Smart Manufacturing Advisory Board.

Mr. Jeff is Accorded with following Honors & Awards :

https://www.linkedin.com/in/je

Mr. Jeff Winter is Bestowed with the following Licenses & Certifications:

https://www.linkedin.com/in/je

Mr. Jeff is Volunteering in the following International Industry Associations & Institutions:

https://www.linkedin.com/in/je

Mr. Jeff can be contacted at :

Email : [email protected], [email protected]

LinkedIn : https://www.linkedin.com/in/jeffreyrwinter/

Also read Mr. Jeff’s earlier Articles :