What does it mean to Digitally Transform?

Jeff Winter, Senior Director of Industry Strategy Manufacturing at Hitachi Solutions, discusses the state of digital transformation in 2023.

Digital transformation, as a phrase and business concept, has consumed marketing content, board room discussions, and consulting engagements for years. Digital transformation, especially in the context of the changes brought about by COVID-19 and the shift to remote work, has become integral to the survival and competitive advantage of companies. It’s often viewed as the incorporation of advanced technologies such as AI, machine learning, automation, and data analytics into business operations.

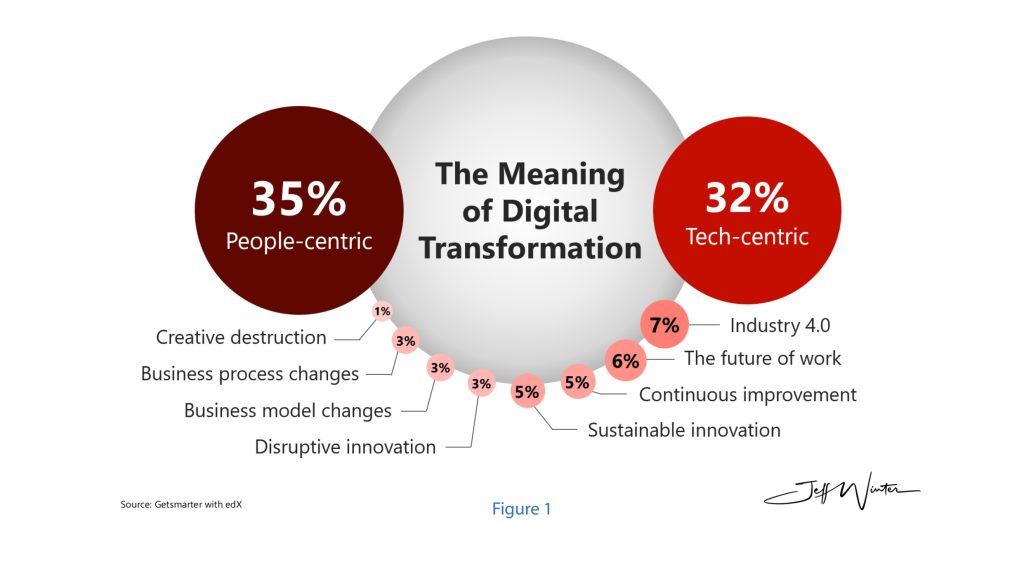

According to a GetSmarter survey, there is a lack of consensus among professionals about the exact definition of digital transformation and its direct impact on their work and career trajectories. Despite its significance, there’s no universally agreed-upon definition for digital transformation, partly due to its broad influence across different sectors and roles. Diverse perspectives exist, from seeing it as the incorporation of digital technology into all business domains to using digital technology to solve human problems (See Figure 1).

According to a GetSmarter survey, there is a lack of consensus among professionals about the exact definition of digital transformation and its direct impact on their work and career trajectories. Despite its significance, there’s no universally agreed-upon definition for digital transformation, partly due to its broad influence across different sectors and roles. Diverse perspectives exist, from seeing it as the incorporation of digital technology into all business domains to using digital technology to solve human problems (See Figure 1).

If its meaning remains unclear and its impact misunderstood, businesses and professionals may fail to create effective digital transformation strategies for the future. Something so seemingly simple as not having a clear definition can have profound impacts including:

1. Misalignment of goals: Different definitions can lead to different visions and expectations. For instance, one team may view digital transformation as moving all operations online, while another team may see it as simply automating specific tasks. This could result in goals that are not properly aligned, causing confusion and potentially leading to initiatives that work against each other instead of for each other.

2. Inefficient Use of Resources: If there is no shared understanding of what digital transformation entails, resources might not be allocated effectively. Some teams might be over-resourced based on their interpretation of what is needed, while others might be under-resourced.

3. Communication Breakdowns: Without a common language or understanding, it can be difficult to effectively communicate plans, progress, and challenges.

4. Poorly Executed Strategies: Different interpretations could lead to different approaches to implementing changes, leading to inconsistency, confusion, and potentially suboptimal results.

5. Reduced Employee Engagement: If employees do not understand or agree with the organization’s digital transformation goals, their engagement and buy-in could decrease. This could affect morale, productivity, and ultimately the success of the transformation initiative.

But what does it really mean, especially in terms of manufacturing? And why does it matter? Lets review a bit of history:

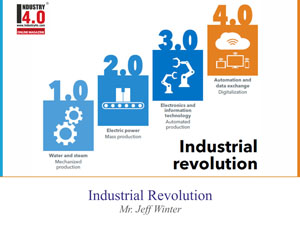

Pre-Internet Era (Pre-1990s): The concept of digital transformation first began with the introduction of computers in business operations. During this era, businesses started to adopt digital technology, replacing manual and analog processes with digital ones. Unfortunately during this period, manufacturing still relied heavily on manual processes, with mechanization and electricity driving most industrial activities.

Advent of the Internet and Digitization (1990s – Early 2000s): With the advent of the Internet, businesses began to use digital technologies to optimize their processes and to expand their reach. Computer-based tools and software started being used in the manufacturing industry, facilitating things like Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and Enterprise Resource Planning (ERP).

Emergence of IoT, Big Data, and Cloud Computing (Late 2000s – 2010s): This period saw the rapid development of technologies such as IoT, big data analytics, and cloud computing. Manufacturing companies began to leverage these technologies to optimize their production lines, reduce costs, and improve product quality. The Internet of Things, for example, allowed manufacturers to connect various devices within their production facilities, resulting in increased automation and efficiency.

Industry 4.0 and the Rise of AI (2010s – Present): The term “digital transformation” became a buzzword in the mid-2010s and has continued to grow since, peaking in popularity within the past two years as evident by the number of Google searches for the phrase. The term “Industry 4.0” was coined in Germany and famously introduced at the 2011 Hannover Fair as part of the German High-Tech Strategy. It refers to the fourth industrial revolution, characterized by smart and autonomous systems fueled by data and machine learning. In this period, manufacturers are leveraging technologies such as AI, machine learning, and advanced robotics to further optimize their operations, improve product quality, and reduce costs. The widespread use of AI in manufacturing has also allowed for significant advancements in areas like predictive maintenance, quality control, and supply chain optimization.

While it’s true that the terms digital transformation and Industry 4.0 have been used extensively in marketing materials and by consultants, it’s important to note that the concepts are not just buzzwords. The process of digital transformation reflects the significant shift that businesses are making to adapt to a world that is increasingly digital. Even though the term might have been popularized by marketing efforts, the process it describes is very real and continues to be a major focus for businesses across industries.

From a technology perspective, the mid 2010s are ancient history, as that is when we saw the release of products like the Apple iPhone 4 (2010), Apple iPad (2010), Microsoft Surface (2012), Microsoft Azure (2010), Instagram (2010), Telsa Model S (2012), Raspberry Pi (2012), and Uber (2011 – expansion outside of San Francisco). Now, in 2023, digital transformation and Industry 4.0 continue to evolve with the development of technologies like AI, machine learning, big data, IoT, and more. As these technologies continue to advance, businesses are perpetually challenged to stay ahead of the curve and transform their practices to stay competitive in a digital-first world.

How Big is the Digital Transformation Market and which Industry is Spending the Most?

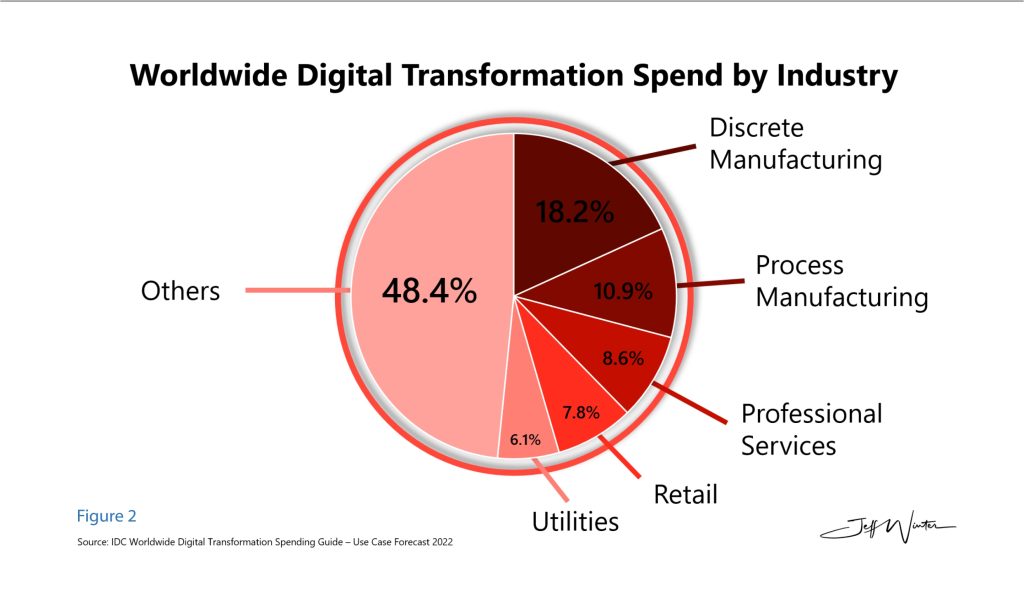

According to IDC, global spending on the digital transformation (DX) of business practices, products, and organizations was estimated at $1.8 trillion in 2022, and will continue to grow with a five-year compound annual growth rate (CAGR) of 16.6%. To come up with this number, this study evaluated 12 technology markets and 300+ DX use cases (See Figure 2). From an industry perspective, manufacturing comprises 29.1% of worldwide DX spending for the year (18.2% discrete and 10.9% process), followed by professional services in a distant second at 8.6%. The category of “others” comprised insurance, securities and investment services, construction, resource industries, wholesales, personal and consumer services, transportation, healthcare provider, media, federal/central government, state/local government, telecommunications, and education.

What are the forces driving digital transformation?

Consumers are demanding more, faster. According to Pitney Bowes, 73% of customers prefer to do business with brands that personalize their shopping experience. Sustainability, being environmentally friendly, and acting ethically have also become decision criteria in the purchasing process. Consumers are also demanding a faster response to sales or marketing questions with faster delivery, right to the doorstep.

Artificial intelligence is infiltrating our lives. AI is extremely versatile in its application — it spans every industry and impacts nearly every job function — from entry level all the way up to CEO. According to PwC, AI is expected to contribute $15.7 trillion to the global economy by 2030.

Innovation everywhere. Companies are formally investing more in creating a culture of innovation, oftentimes resulting in adopting the new role of Chief Innovation Officer. The Global Innovation Index shows that investment in innovation has been resilient during the COVID-19 crisis and even reached an all-time high with R&D expenditure growing by 5.2% in 2021 and 7% in 2019, a rate unseen since 2014.

Government assistance. Whether it is the U.S.’s Manufacturing USA initiative or Germany’s High-Tech Strategy 2020 or China’s Made in China 2025, governments around the world have been investing billions in developing manufacturing technologies to help overcome technical hurdles and train tomorrow’s workforce to spur the next wave of global economic growth.

Data is everywhere. Humans and machines are creating far more data than we know what to do with. Those that can capture and harness the power of data will have a massive competitive advantage. According to Statista, we are anticipated to produce an estimated 120 zettabytes of data in 2023 (which is roughly 24,000 times as much as the data created by all of humanity up until 2003).

How successful are companies in digitally transforming?

Back in 2016, McKinsey & Company shared a study that showed a whopping 70% of digital transformations fail. But since 2016, surely things have gotten better, right? Let’s review a few other findings:

In 2020, Boston Consulting Group (BCG) found 70% of digital transformation projects fell short of their goals — even when leadership is aligned.

In 2021, an Everest Group study found that 68% of companies failed to provide any business value from their digital transformation process.

In 2021, a Couchbase study showed that 82% of enterprises were prevented from pursuing digital transformation projects, and 80% had projects fail, suffer delays, or scaled back.

So, after finding four studies, created by four different companies spanning five years, saying basically the same thing — begs the question: What gives?

Unfortunately, there is no simple or single answer. Truly successful digital transformation requires a total redesign of how your business operates, generates revenue, approaches problems, and even engages with employees and customers. Furthermore, this transformation will result in the people needing to change as much as the company itself.

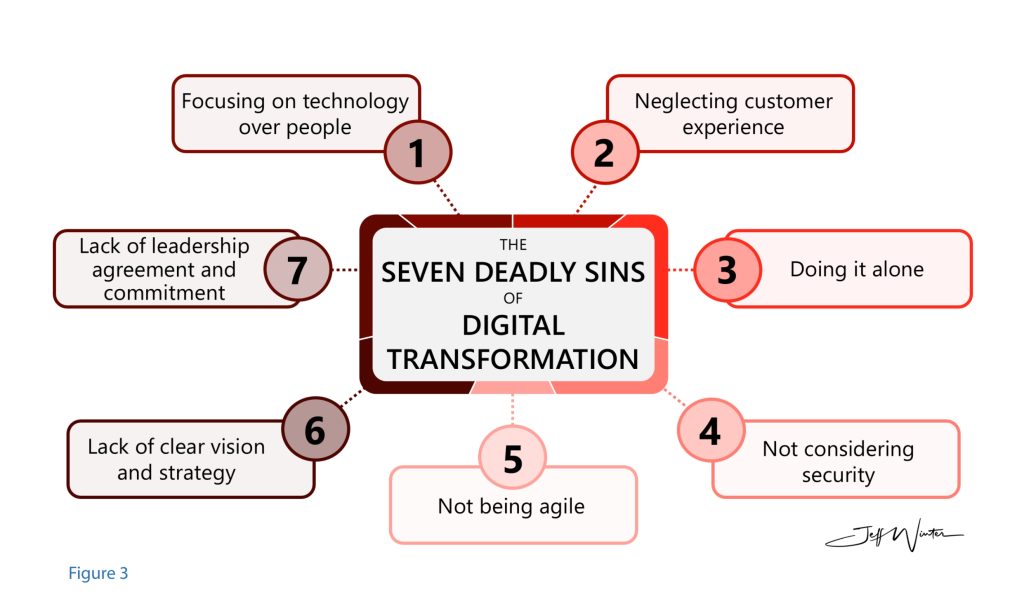

From personal experience, there are a few common failure points in digital transformation, or what I like to call The Seven Deadly Sins (See Figure 3):

1. Focusing on technology over people: While technology is certainly an important aspect of digital transformation, it’s arguably more important to consider how the changes will impact employees. According to Boston Consulting Group, in a study for 40 digital transformations, they found the proportion of companies reporting breakthrough or strong financial performance was five times greater (90%) among those that focused on culture than it was among those that neglected culture (17%). Strong leadership and good change management will help ensure employees are inspired, motivated, and aligned with the digital strategy.

2. Neglecting the customer experience: Customer experience must be at the heart of digital transformation. Process optimization and cost reduction will help improve the business, but they won’t change the game. Leveraging high-quality product, customer, and market data allows companies to create new business models that provide better product/service performance, customer experience, and business outcomes for customers.

3. Doing it alone: Adopting and implementing a variety of new technologies that need to cohesively work together while simultaneously modifying processes and managing cultural changes is a tough undertaking. Very few companies, if any, have the expertise and experience in-house to pull off a successful digital transformation by themselves. The right partner ecosystem brings diverse skills, industry insights, and proven methodologies, thus reducing risk and accelerating transformation. Partners can provide tailored solutions that match your specific needs, offering scalability and flexibility.

4. Not considering security: As organizations adopt new technologies, it’s important to consider the security implications for the organization and for the customers. Cybersecurity is too important to be considered an afterthought in the digital transformation process. According to Microsoft’s Digital Defense Report 2022, manufacturing at 28% had the highest ransomware incident and recovery engagements of any industry.

5. Not being agile: Very few large-scale transformations go exactly as planned. In addition, technological advancements and market conditions are changing so fast that failure to react and adapt quickly can be catastrophic. Agility also encourages cross-functional collaboration, transparency, and an iterative approach. Without this, resistance to change may flourish, leading to a lack of alignment between departments and undermining overall business objectives. This resistance can stagnate the culture of continuous improvement, further reducing the organization’s adaptability.

6. Lack of a clear vision and strategy: Not everyone has the same definition of digital transformation. According to Baker McKenzie, 69% of organizations define digital transformation as a tool for improving process efficiency. Meanwhile, 23% view digital transformation as a tool for developing new ways to sell products and services, and only 8% think of it as a developing business model change. A good digital transformation strategy should include a vision that aligns with business objectives, describe what success looks like, how success will be graded, how the combination of technologies will be integrated across all systems and processes to transform the business, and a transition/change management plan. A simplified digital transformation statement should be continually communicated to all employees, with managers ensuring their employees understand exactly how their role fits into the transformation and the outcome.

7. Lack of leadership agreement and commitment: Digital transformations are designed to be disruptive and can often be costly. Company leaders not only need to agree on the digital strategy, but they also must be fully committed. Otherwise, digital initiatives will run the risk of goal and priority misalignment, high levels of resistance, and loss of funding.

Digital business transformation is a multifaceted process that involves a wide range of strategic changes and adaptations across an organization. It is crucial to recognize that there isn’t just one type of digital transformation; rather, it encompasses various aspects such as process, business model, cultural/organizational structure, customer experience, domain, and ecosystem transformation. Focusing solely on one dimension can limit an organization’s overall success and hinder its ability to thrive in a rapidly evolving digital landscape.

The leaders and managers of a digital transformation initiative need to understand and fully appreciate that success requires a change in behavior and attitudes of those involved, not just a replacement in technology and processes. Technology is an enabler of transformation, not the goal of transformation.

Digital transformation should be viewed as a strategic initiative, not a set of tactical to-dos. This means it can’t simply be assigned to others to complete — it requires a company-wide all-in mindset focused on a shared mission. It is part of the long game, not a yearly or quarterly accomplishment.

About Jeff Winter

Jeff’s passion is helping manufacturers digitally transform in innovative ways through Industry 4.0 technologies. Doing so requires a unique ability to bridge the gap between business strategy, industry trends, technology implementation, and change management.

Jeff enjoys building collaborative relationships with clients, partners, coworkers, and industry evangelists to help empower manufacturers to achieve more. As an industry strategy leader for manufacturing for Hitachi Solutions, he focuses on helping companies that build things (discrete manufacturers) or stuff (continuous/process manufacturers) digitally transform.

Jeff is very active within the industry as a thought leader to help inspire companies, professionals, and students to be excited about the future created by the fourth industrial revolution.

To Download this Article in PDF Format

About the Author :

Jeff Winter is an Industry 4.0 & Digital Transformation Enthusiast | Business Strategist | Avid Storyteller | Tech Geek | Public Speaker

Jeff Winter with over 15 years of experience working for different industrial automation product and solution providers, Jeff has a unique ability to simplify and communicate complex concepts to a wide range of audiences, educating and inspiring people from the shop floor up to the executive board room. As part of his experience, Jeff is also very active in the community of Industry 4.0.

Jeff is a part of the International Board of Directors for MESA (Manufacturing Enterprise Solutions Association), he is in the leadership committee for the Smart Manufacturing & IIoT Division of ISA (International Society of Automation), he is a U.S. registered expert for IEC (International Electrotechnical Commission) as a member of TC 65, and also part of Purdue University’s Smart Manufacturing Advisory Board.

Mr. Jeff is Accorded with following Honors & Awards :

https://www.linkedin.com/in/je

Mr. Jeff Winter is Bestowed with the following Licenses & Certifications:

https://www.linkedin.com/in/je

Mr. Jeff is Volunteering in the following International Industry Associations & Institutions:

https://www.linkedin.com/in/je

Mr. Jeff can be contacted at :

Email : [email protected], [email protected]

LinkedIn : https://www.linkedin.com/in/jeffreyrwinter/

Also read Mr. Jeff’s earlier Articles :