Modern theories of firm strategy integrating various analytics has not improved bottom line…. Disruption and Growth is the biggest organizational dilemma. Growth is directly proportionate to shrinking leadership ability.

Acknowledging World class Status

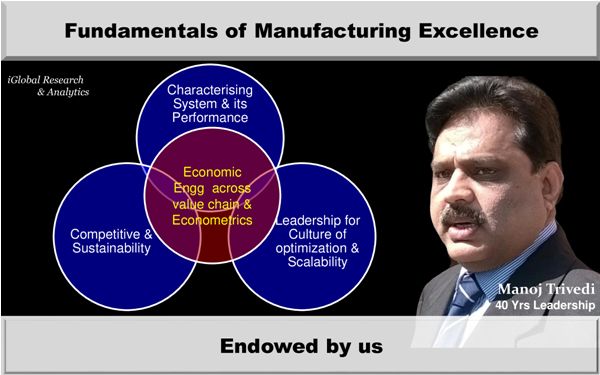

Manufacturing excellence has the ability to bring world class stature provided it is understood, implemented and practiced well. Being best of the best with ability to provide high quality, competitively priced products and services in a global marketplace—is a biggest dilemma and major hurdle confronting manufacturers.

Manufacturing has to look beyond assembly of parts or preparing input baskets for value added products. Manufacturers need to ask themselves–why their produce fetches higher profit of more than 20% to their dealers while their own profit is limited within 10%! Because, there is a difference between trading business & manufacturing business. Manufacturing being a dignified activity is more than just business and involves entrepreneurship with risk taking and innovative ability. Manufacturing is governed by various factors. All these factors are governed by its own dynamics. Whereas most of the organization have customer oriented focus. The challenges manufacturers face are well known: the need to improve product quality, drastically shorten product development cycles, increase productivity growth, stimulate product and process innovation, and respond quickly to changing customer demands.

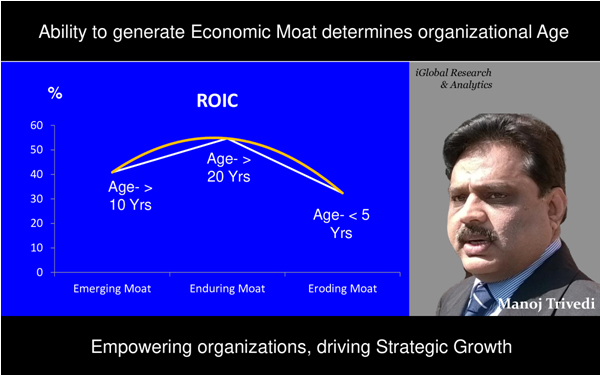

Globalized world and Free Trade Agreement out of WTO ruling combined with threats from new entities, supply chain efficiencies and ever changing macroeconomic forces has put organizations under great stress and sustainability threat to think about their conventional practice and casual approach. Digital disruption has further brought the market closure and confined within the idiot box. Customers now have many choices. Market has surpassed oligopoly. Rising competition gives rise to uncertain conditions. VUCA world is fast changing to greater amount of volatility and uncertainty. Poor returns have become detrimental factor to determine the age of organization.

Manufacturers can no more depend upon fortuitous return based on market dynamics. Unless they plan their business based on cost price threshold determining their return, it will be difficult for them to survive beyond certain period.

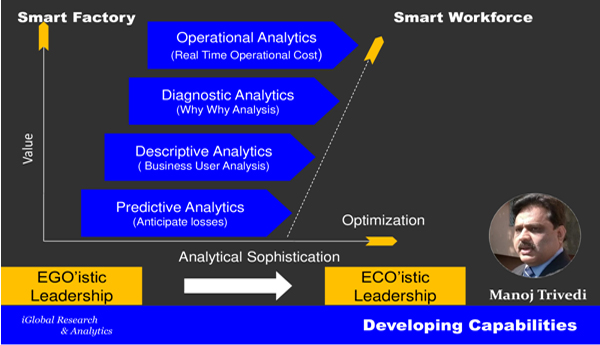

We should not be discouraged nor paint too broadly the malaise of Indian manufacturing capability. Recognizing growing complexities, global shift and the need, Indian manufacturers have started looking beyond Customer Analytics to focus on Operational Analytics. Crave for manufacturing excellence has begun to show. An expanding core of Indian manufacturers has begun to appreciate the level of performance and commitment needed to adequately confront competition in both domestic and foreign markets. They are undertaking the kind of changes and improvements in organizational structures, governance, and relationships that are needed to create the level of manufacturing excellence demanded by increasingly sophisticated and quality conscious customers around the world.

Manufacturing as a System

Manufacturers have to develop a science of manufacturing to understanding and improving the performance of the many unit operations and activities. Our perception of the manufacturing process has centered on the materials, machines, finance, labor, and equipment used to make products—the physical processes of production—and, to greater extent, the data and information flows among the computers and controls for these processes as facilitated by modules of AI. Accordingly, institutional examination of manufacturing has to be evolved into a collection of narrow disciplines that customarily ignore the integrated nature of the manufacturing system.

It is has to be developing greater understanding of the fundamental phenomena underlying the unit operations and subsequently maximizing the effectiveness of the separate parts, that the entire system can be optimized. We have to realize that the number and complexity of the relationships, interactions, and dependencies of the components and processes precludes such a piece-meal approach to system optimization. It is clear that we need a dynamic and integrated concept of manufacturing systems.

In the absence of an overall understanding of the system and interrelationships among the functions, however, operational models have to be evolved from beliefs or rules of thumb derived from personal experience, trial-and-error, and individual interpretation of empirical data. But this so called know-how varies widely in extent and validity from company to company and from industry to industry and is almost always impossible to generalize or apply to new situations.

The manufacturing excellence, therefore, cannot be based on generics. It has to be based on individual business dynamics, market dynamics involving product & process combined with socio-economic-politico & demographic need. In short, strategizing customized need shall be the essence.

The system need to be built fool-proof involving no element of error or deviation to work on value chain with due participation of all the employees across functions and hierarchies.

Leadership and Management

Leadership and management of the world-class manufacturing organization has to relentlessly evolve from an operational mode characterized by system driven command, control, and maintenance of the status quo and innovation based—an inappropriate approach to the chaotic environment confronting manufacturers today—to a dynamic model requiring innovative leadership, strategic vision, and radical reformulation of organization structure and administration. This may include substantial changes in employee, customer, vendor and supplier relationships, and the adoption of a more holistic perspective on the interdependencies among the many elements of the manufacturing system. In this section we look at six fundamentals of manufacturing excellence that must originate from, and therefore be supported by, the executive officers of the enterprise.

The leadership has to look beyond objective principles of management inspiring team to continuously work on innovation and replacing with subject need.

Executives must clearly articulate and communicate the vision and philosophy of the corporation; ambiguous objectives are of no help when employees try to choose from among a host of uncertain alternatives as they race to identify and address new product trends while retaining current customers.

Characterizing the system and performance

Understanding market dynamics and competitor’s capability is but the first step in becoming competitive. It is difficult to conceive of improving the current status of the system without first having a clear description of its status and character. This requires identifying the operational variables, understanding the interrelationships among them, and determining the theoretical limits of the variables and the system they constitute. It demands that important system parameters be identified and measured with tools of value stream mapping and loss-cost matrix. Identifying cause-and-effect relationships that help predict the consequences of actions provides a basis for developing general tools and procedures that will allow the practitioner to extrapolate beyond current operating experience and to anticipate more accurately how a future system may respond or perform. The extent to which modelling, simulation, and analysis can be developed to provide these capabilities is an important element of manufacturing excellence.

Matrices

Metrics are absolutely fundamental to achieving manufacturing excellence. They are the basis by which the organization describes quantitatively the expectations and criteria used to measure the performance of the manufacturing system and its many interrelated components. Measuring, Control & Determining cost components on real-time basis will enable competitiveness.

Manufacturing excellence requires an appropriate strategy for benchmarking: providing the resources, identifying the correct metrics within the context of their firm, overcoming the organizational resistance to “sacred cows” that in the past have been “unmeasurable,” and surmounting the political situations that impede exchange of benchmark information. The sad truth is that many manufacturers have never looked at the performance of their domestic and foreign competitors. More often than not they evaluate their performance relative to their own accomplishments in previous periods, ignorant of the high levels of achievement possible.

Leaders can no more rely on the plate they are served. They have to know their organisations strength and weaknesses with full grip over economic moats to work on cost to customer advantage.

Companies must measure their performance by benchmarking themselves not only against their competition but also against the best-of-the-best functionally, even in other industries. Manufacturers have to compare their customer service operations to the services provided by leading department stores, mail order firms, or medical services providers. They need to customize their cost, price and service based on market needs and customer requirement for competitive advantage. They must base their organizational goals and objectives on this information, continuously measuring and assessing the performance of the system against these objectives to determine whether they are indeed improving, and then regularly assess the appropriateness of the objectives to attaining world-class status.

Sustaining the Future

The “manufacturer of the future” faces two significant challenges: intense competition and incessant change—new science and technology, new product and process, new customer and market, new regulation and constraint. The globally competitive manufacturers will be identified by the rapid, flexible, and innovative fashion in which they respond to those dynamics, and by the quality, competence, and motivation of their work force.

There are two generally separate but related ways that the manufacturing firm will be able to create the necessary resources and capabilities to respond in such a manner. The first is the ability of the organization to learn and improve. The organization that can learn more rapidly from its experiences and use that learning to enhance its performance will have a distinct advantage. The second answer is to be found in technology. The enterprise that develops the ability to lead in the effective use of technology will possess a distinct and important advantage over competitors.

Maintaining and achieving enhanced system performance, however, requires an environment in which an organization can learn and benefit from its past experiences. As operating practice becomes more efficient through the application of the foundations of manufacturing, technology will become a more critical element in maintaining the status of the world-class competitor. The arrangements for acquiring, developing, and introducing new technology will become increasingly important as Indian manufacturers continue to develop their abilities to compete in the world marketplace.

Learning and Experimentation

Maintaining manufacturing excellence depends upon an organization’s ability to stimulate and accommodate continuous change. Experimentation and response to change creates new learning opportunities and organizational knowledge that lead to improved operational decision making.

The ability to react quickly and adjust to change is a skill that can be cultivated by encouraging and supporting intelligent risk takers and their experiments at all levels of thè firm. But experimentation can disrupt established norms of operation, and the firm that wishes to experiment must recognize and allow for this disruption. The manufacturing organization is also challenged to create the environment and ensure circumstances that support venture and experimentation without placing the job security of risk takers in peril—employees must feel a sense of “protection” if they are expected to be innovative.

Technological Support

Technology with modules of AI has to be a fundamental means for sustaining world-class competitiveness by all elements of the manufacturing organization. High priority must be placed on the discovery, development, and timely implementation of the most relevant technology and the identification and support of people who can communicate and implement the results of research.

The technology must have a blend of Human & Machine intelligence to collaborate & work hand in hand for best results and return. For management, selection of the proper technologies from among technological opportunities is becoming a complex challenge that may be different for each manufacturer and for individual facilities. Choice of the appropriate technologies will increasingly consider local circumstances such as environment, work force, materials availability, relative costs of production, and the abilities of competitors. By making use of leading-edge technologies, a manufacturer may be able to achieve lower costs, better quality, or greater customer satisfaction with existing products by making low-cost variations in small lots and thereby realize significant competitive advantages.

General notion that technology can reduce employment cost eliminating blue collar worker is a myth. To construe technology alone can take care of organizational requirement and run the organisation is also a myth. If not planned in a proper way and without choosing appropriate technological tools will lead to nowhere.

Return on Investment

Manufacturing organizations are unable to work out on return on investment for technological adoption. This admittedly and evidently reveals they have no idea of requirement of Industry 4.0 and likely benefits. For adoption, they are largely dependent upon external agencies for huge consideration. Developing capabilities they can develop required infrastructure at about 90% less project cost with an ability to reduce about 20-30% on operational cost y-o-y.

Conclusion

The core characteristics of manufacturing proficiency in an increasingly competitive international marketplace involve superb skills & capabilities, operations efficiency, quality conscious customer satisfaction, and innovative adoption of product and process technology. Building industry specific capabilities is central to success and hallmark of world-class manufacturing capabilities. The responsibility to prepare capabilities lies on manufacturing entities. Since these capabilities are system based, there can be no fear of investments go waste as such capabilities and skills are industry specific.

About the Author

With four decade bottom up industrial leadership Manoj Trivedi, Founder Director & Business Mentor at iGlobal Research & Analytics, is the only facilitator engaged in developing capabilities, performance pillar and required skill of Industry 4.0 for being cost efficient and competitive while helping industries through value stream mapping & assess requirement of tools of AI based on its dynamics. He undertakes short/long term contract as may be required in preparing industries for the challenge. He may be contacted at (91) 9051831961. Alternatively, you can reach him at [email protected].

Also read my earlier articles