Abstract

Development and hype around the “Metaverse” are accelerating at the speed of light. Let’s humbly accept the fact that we still are in the nascent stage of this technological evolution. During the early days – VR headsets were perhaps only viewed through the lens of gamification and entertainment of content. The limitless potential of any disruptive technology is truly felt only when it evolves more than just a FAD and having said this, I leave it to the individuals’ understanding that Metaverse is the next leading technology where all the firms would eventually end up, more specifically healthcare, manufacturing, and retail.

By large the best and most powerful use case of the metaverse is seen in the health care sector-next only to the entertainment industry/sector. Slowly and steadily the dawn of metaverse in manufacturing is raising. Metaverse is a set of technologies that allows for persistent, digital representations connected to aspects of the real world, like people, places, and things. It would be only fair to say that in a limited capacity metaverse in a way is an extension of the digital twin.

By large the best and most powerful use case of the metaverse is seen in the health care sector-next only to the entertainment industry/sector. Slowly and steadily the dawn of metaverse in manufacturing is raising. Metaverse is a set of technologies that allows for persistent, digital representations connected to aspects of the real world, like people, places, and things. It would be only fair to say that in a limited capacity metaverse in a way is an extension of the digital twin.

Why does Manufacturing need to embrace this amid industry 4.0?

At a holistic level metaverse in the manufacturing can address the following

A. Faster, smarter, and innovative training models.

B. 3D modeling and engineering.

C. Using Augmented reality for field service

Let us understand each one of them

A. Immersive Training:

All the four industrial revolutions have evolved around the two major key KPIs

- Overall equipment effectiveness and

- Increased productivity

In the enduring quest towards leaner and cleaner production management safety and employee training perhaps were alphabetically in the order of letters y & z, such has been the domination of the process-related KPIs, often side-lining the safety and employees training. The approach toward workplace safety saw drastic improvements after rigorous safety laws and ISO regulations codes were made absolute mandates. Safety is largely cultural and mindset aspect rather than the code of conduct. It is this culture that needs to run in the arteries and veins of the organization and the employees as the saying goes “A spark neglected, burns the house “

Existing training methodologies are

1. In consistent

2. Are boring

3. But most importantly scalability is the major bottleneck.

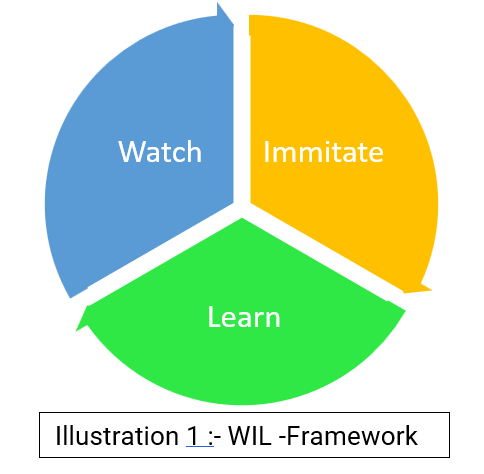

Immersive training addresses these three key issues. First and foremost, consistency in the training is achieved via the WIL framework (learning by imitation). It is based on the phenomenon of learning by watching. Living specie by has a built-in cognitive system that has a natural inclination toward learning by imitation. An infant’s first learning effective kick- starts by imitation, and nature has built this profound yet simple ecosystem in and around us.

Immersive training addresses these three key issues. First and foremost, consistency in the training is achieved via the WIL framework (learning by imitation). It is based on the phenomenon of learning by watching. Living specie by has a built-in cognitive system that has a natural inclination toward learning by imitation. An infant’s first learning effective kick- starts by imitation, and nature has built this profound yet simple ecosystem in and around us.

Secondly the concept of immersive learning – is that it combines the sense and presence of VR with learning theory– improving the learning experience of employees/users, especially novices, rather than having them sit in a classroom all day.

Employees also get the benefit of being able to make mistakes in a virtual environment without real-world consequences, compared with on-the-job training with heavy machinery or hazardous/dangerous environments.

The beauty of metaverse is the fact that – a whole new immersive experience is created and the same gets burned deeply in the memory of the end-user or trainee. The fact that users can consume the content in true depth 3D eliminates the disengagement proportion, studies have clearly shown that the user’s/trainers’ engagement index/rate is 4x more than usual methods which in itself is a statement towards the effectiveness of the training delivered via this methodology and this can be coined as FSC system which stands for faster, smarter and creative.

B. 3D modeling and engineering

Part of the metaverse includes technologies such as digital twins, where all the components of a physical location (or product) are digitized to produce a virtual “twin” Digital twins can be used to compare the “as-is vs to-be” designed products.

By setting up virtual environments, potentially looking through the various optics ranging from designing to troubleshooting and outlaying the hands-on issues, followed by necessary changes before commencing the final manufacturing. The bridging of the physical world to a virtual world will provide multiple avenues for potentially unlocking new ways of resolving the hands-on challenges, thus saving valuable resources material, money, and time.

C. Augmented reality for field services.

Similar to training modules and LMS programs for new employees, field service workers, and technicians can also get assistance from erection to troubleshooting via the 3D content from the digital library of the equipment. The created content becomes the digital library of the organization.

Usually, when the employee(s) leave the organization, despite the fact the KT is obliged, the experience of the employees is not transferred completely or captured creating a vacuum. The Metaverse provides us the opportunity to capture, create and retain the expertise in a 3D form that is easily understood by all rather than going through legacy methods.

By large the maintenance activities are predefined and fixed, and the occurrence of an acute problem is rare in nature, thanks to AI-driven maintenance, allowing the manufacturers to depict every possible failure scenario and create a digital library depicting all permutations and combinations. The 3D podcast is the most valuable asset for the organization as this would standardize and ensure consistent delivery of the SOP across the length and breadth of the organization.

Summary

Infinite possibilities await manufacturers who don’t wait and the sky is the limit. Traditionally, manufacturers have often been slow to adopt new technologies, but experts in the metaverse believe the opportunities are too great for manufacturers to sit on the sidelines. Industrial Metaverse helps manufacturers digitally transform their businesses, but they will be paramount in creating the paradigm shift when it comes to enhancing the OUT for their employees (onboarding, training, and upskilling ).

All manufacturing industries have developed a standardized and robust process. But there is no standardized/baseline matrix to understand the skill mastery level of the training program and content itself. Making the training experience inconsistent and boring activity, this is precisely where metaverse as technology can give a scintillating experience for the users.

About the Author :

Mr. Prasanna Upadhyaya

Head – EIS, 8Chili Inc

Prasanna is a Digital Manufacturing Leader with a proven track record of successfully executing Industry 4.0 initiatives with a focus on ROI and Sustainable manufacturing.

Prasana has strong data driven abilities and a clear understanding of Internet of things, business transformation process, ROI modelling, ERP implementation and integration, supply and demand side economies and its impact on manufacturing.

Prasana is Bestowed with the following Licenses & Certifications :

https://www.linkedin.com/in/pr

He can be contacted at :

Email : [email protected]

LinkedIn : pr

Twitter : https://twitter.com/pkupadhyay22

Also read his earlier article: