Drive Sustainability with Industry 4.0

Sustainability and Its Relevance for Manufacturing Organizations

We may all agree that sustainability is one of the key aspects for businesses and individuals to consider for day-to-day activities and operations. With the threat of climate change looming over, over usage of fossil fuels leading to huge pollution and energy crisis due to physical and man-made reasons, sustainability is the aspect that no one can ignore now.

Furthermore, it is even more important consideration for businesses and especially manufacturing organizations who anyway need to consume large amounts of energy, generate waste and GHG emission and thereby may affect the environment due the nature of its business activity. With the physical threats for the planet and environment and also government taxes and regulations to optimize the above, organizations nowadays must have a solid strategy to optimize and move towards net zero goals. So, what is the approach for managing and controlling the waste, energy usage and overall sustainability especially for manufacturing organizations?

Here comes the concept of Industry 4.0 which is another key consideration for manufacturing organizations to integrate and digitalize physical operations with the view of driving more benefits for the business such as optimizing resource downtimes, increasing yield, and improving quality. But improving sustainability, which is nevertheless one of the very important factors for consideration for both business and personal lives, can be one of the key outcomes of Industry 4.0 if strategized correctly.

Framework and Goals for Sustainability Measurement & Optimization

First of all, if you want to optimize and control something you need to measure it. ESG framework which stands for Environmental, Social and Governance framework has been defined to identify and measure sustainability KPIs as part of Sustainable Development Goals (SDG) which can be reported through the GRI (Global Reporting Initiative) index. There are 17 SDG defined in https://sdgs.un.org/goals as below:

SDG 1: No Poverty

SDG 2: Zero Hunger

SDG 3: Good Health & Well-being

SDG 4: Quality Education

SDG 5: Gender Equality

SDG 6: Clean Water & Sanitation

SDG 7: Affordable & Clean Energy

SDG 8: Decent Work & Economic Growth

SDG 9: Industry, Innovation & Infrastructure

SDG 10: Reduced Inequalities

SDG 11: Sustainable Cities & Communities

SDG 12: Responsible Consumption & Production

SDG 13: Climate Action

SDG 14: Life Below Water

SDG 15: Life on Land

SDG 16: Peace, Justice & Strong Institutions

SDG 17: Partnership for the Goals

Though many of the SDGs play an important goal for manufacturing organizations, SDG 12: Responsible Consumption & Production and SDG 13: Climate Action are the most relevant for manufacturing industries having generating emissions and waste which may impact the environment if not managed properly, along with the social and governance topics as well. The ESG metrics for an organization are quite important nowadays for regulators and governments, investors as well as the customers.

Most of the emission and waste for manufacturing organizations are generated during the manufacturing execution process in the factories which need to be tracked so that it can be optimized. The emission are mainly categorized as:

- Scope 1 – the emission which are generated by the organization directly and can be controlled directly by the same organization.

- Scope 2 – the emission which are generated by secondary sources such as energy providers which are consumed by the organization.

- Scope 3 – other sources of emission which are related to transporters, service providers, etc. which are used by the organization.

Industry 4.0 as an Enabler for Sustainability Tracking & Controlling

To track and control the sustainability parameters as per ESG framework you first need to do materiality analysis to identify the factors that lead to the GHG emissions and generating carbon footprint. Typically, the factors to determine the carbon footprint in manufacturing operations may be multiple and below are some examples:

Scope 1:

– Quantity of emission of GHG from manufacturing operations

– LPG consumptions in manufacturing operations

Scope 2:

– Electrical energy consumptions in manufacturing operations

– Heat/Steam consumptions (purchased directly) for manufacturing operations

Scope 3:

– Material inventory movements inside and to and from the factory and warehouses

– Quantity of waste generated from manufacturing operations

– Paper consumed in manufacturing operations

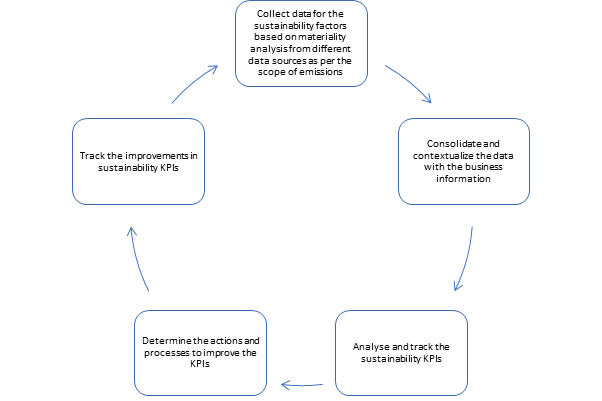

The approach to track and improve sustainability is depicted in the diagram below:

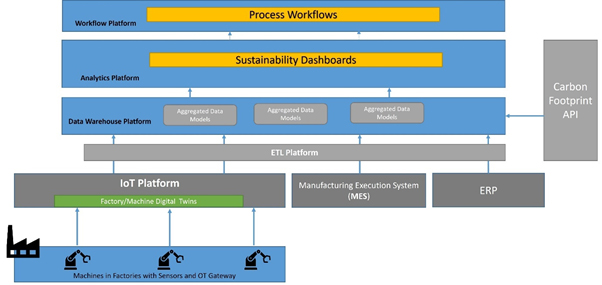

Industry 4.0 initiatives drives integrating your machines on the shop floor with the execution and planning systems, which helps to get real-time and granular information about the operations such as yield, waste, energy consumed, emission generated, etc. To enable this, you need to have the sensors and smart meters installed at the production lines and machines, which is one of the key activities you need to undertake to start the journey of Industry 4.0, if not already available. It should also enable bi-directional integration with the planning and execution systems to control, manage and measure the key data for the operations.

You need have a mechanism to collect the energy consumption, waste generation along with yield data, inventory movements from the manufacturing operations directly from the machines through sensors ideally. If manufacturing execution system (MES) is implemented already, then most of the data for manufacturing operations may be captured and available from the MES itself, especially the yield data, as that is usually captured as part of the manufacturing execution process. The sensors, smart meters and connectivity with the machines and production lines is important as that way you can ensure the accuracy and granularity of the data, which otherwise if captured through manual inputs only, may not be available to the fullest extent.

In case a single system is not available to collect and contextualize all the data needed from the manufacturing operations, you need to implement a data collection and contextualization mechanism, by collecting the data from the different sources such as Plant Historian, Energy Management System, ERP, etc. and link it to the relevant master and planning data to determine the emission and waste generated-and energy consumed for unit production. You can leverage event-based data collection mechanism for the manufacturing plant into an IoT platform which can collect the time-series data contextualized with the corresponding asset, from the sensors, gateway or application through various connectivity protocols.

Though you can collect the Scope 1 & 2 parameters relatively easily, collecting Scope 3 parameters may be sometime difficult and need collaboration with logistics partners, suppliers, etc.

After collecting and contextualizing the data, you need to move the data into a data warehouse and analytics platform where you can persist the data and create the analytics to continuously track and monitor the KPIs relevant for ESG and the SDG goals.

Additionally, you may need to generate the compliance reports for GHG emissions which need to be reported to the certification and government authorities in specific formats such as GRI Sustainability Reporting Standards.

The objective here is to determine the carbon footprint across all your processes from the emission, energy consumptions and other processes that are generated or consumed in the manufacturing process. But at the same time, it is needed to corelate the sustainability data with the workcenters or production line and the yield to determine the carbon footprint for each production line or unit of production based on the process and type of assets and materials. For certain data such as GHG emission it may or may not be possible to collect for each machine or production line, though it is recommended and ideal if by placing the sensors and smart meters if the data can be collected for each machine. In case the data you are collecting are not for specific machines or production line and for an area/unit, group of machines or production lines, you need to use an algorithm to distribute the data across the individual machines or production lines based on yield, process type, etc.

To derive the carbon footprint for each type of emission or materiality, you can use the different solutions or APIs available for calculate carbon footprint from an emission or activity type. There are quite a few solutions and public APIs available using which you can calculate the carbon footprint for energy usage, emission, paper consumed, etc.

Collecting the above data and aggregating and contextualizing them, you can provide the analytics dashboard to show the trend of carbon footprint across the different operations and production lines and measure its correlation with the yield. Also you can use machine learning models to predict the different emissions based on the production activities, so that you can optimize them during the production planning.

It is also important to take action to control or mitigate the carbon footprint wherever possible. Analysing the sustainability metrics you can identify certain actions to optimize the carbon footprint e.g. distributing the yield across production lines, checking maintenance or replacement of machines where needed, using alternate materials, etc. For each action identified and proposed you can define a workflow or tracking mechanism to implement the same and then again analysing the carbon footprint once implemented, thus tracking the reduction. It is also important to define and track the mitigation activities to counter the carbon footprint such as using solar energy instead of electrical energy, planting trees, etc. which also need to be tracked as your net zero activities and thereby determine the net zero achievements based on the total carbon footprint generated and total carbon mitigated by the actions.

Below diagram depicts the solution architecture of the sustainability tracking and optimising solution as explained above.

So as explained above Industry 4.0 approach can be utilized to effectively track and monitor sustainability metrics and also to optimize them.

About the Author :

Mr. Dipankar Saha

Principal Architect (Industry 4.0)

Incture Technologies

![]()

Mr. Dipankar Saha is an IT Architect having 20+ years of experience with specialization on Industry 4.0 & IoT solutions, SAP Manufacturing, Microservices & Cloud Applications Development and Intelligent Workflows.

He is experienced in defining architecture and leading implementation of Industry 4.0 solutions for manufacturing execution, analytics, and integration and has led several large and complex Industry 4.0 implementations globally as well as worked on product development.

He has co-authored several professional books on SAP Manufacturing solutions (SAP MII, ME, OEE) which have been published from renowned publishers e.g. SAP Press, Apress & WisPubs and published whitepapers in online journals.

Currently he works at Incture Technologies as Principal Architect.

Mr. Dipankar Saha is Bestowed with the following Licenses & Certifications :

https://www.linkedin.com/in/di

Mr. Dipankar Saha can be contacted at :

Also read his earlier article: