“Industry 4.0, or the Fourth Industrial Revolution, is bringing about a paradigm shift that will profoundly change the way we work, live and interact and will affect industrialized as well as industrializing economies alike.” LI YONG, Director General of UNIDO

More than 90% of CXOs have no idea of requirement of Industry 4.0 and risks associated with it…. Mere adopting tools of AI will not yield desired result unless supported by robust Performance Pillar– PwC in a recent survey report

The purpose of this article is to bring clarity about Industry 4.0 within the Organizations, Business Leaders & CEOs, how to save huge cost in technological adoption & operational cost, take their organizations forward to whole new level of sustainable paradigm, be cost-efficient & globally competitive enduring growth….. Striking a balance between the technology & performance pillar with sustainable product and sustainable organization is the essence of modern day organizations. Encouraging real economic players, investors and governments to work with a common purpose in the pursuit of a global sustainable market movement is our key themes…. Every organization looks at building competitive advantage. Here is how to leverage huge opportunity to capitalise…..

Decoding the Myth

UNIDO said “Major technological advancements have been revolutionizing industrial production ever since 1867, where automation of manufacturing processes is upgraded with smart autonomous systems capable of producing more with less human intervention. Industry 4.0 is meant for self-cognition, self-optimization, and self-customization. Industry 4.0 is accompanied by increased demand for science, technology, engineering and math (STEM) qualifications in manufacturing. In the STEM environment, the skills bottleneck is likely to be felt most in developing countries, because of significant information asymmetry in new technologies, with a huge difference in the level of access to knowledge between developed and developing countries, between rich and poor, and between large and small firms”.

It further confirmed, the purpose of Industry 4.0 is more about reversing FDIs that has been outpouring to Asian countries given availability of Labours and huge market. Western countries in order to lure industries back to their countries have worked overnight to digitise and automate entire production system to prevent human intervention and do away dependence on labours. But this move has not yielded any result. This is not likely to yield any further result if our industries add value to their economies looking beyond the technology.

We must appreciate and agree on some advantages of the technology. Automation and robotics are the key components – the arms and legs – of Industry 4.0; cameras and other sensors are perceived as the senses; data and connectivity are compared to the nervous system; and artificial intelligence (AI) is the brain that enhances industrial processes by enabling the synergetic collaboration between humans and robots in smart factories for mass customization.

Production systems are becoming more dynamic, flexible, efficient, environmentally sustainable and inclusive through extensive customization and personalization ever since 1867. Decrease in material resources and energy consumption, new product designs is being introduced to optimize the use of new advanced materials and nonmaterial’s with beneficial properties, shorten transport routes, and cut transaction costs. Industry 4.0 is also contributing to realize circular economy, in which end-of-life products are reused and recycled, and is facilitating the reaping of benefits and opportunities from this.

This transformation is also bringing with it a change in the nature of jobs & skills requiring not only increased technical competencies but also robust analytical & interpersonal skills, and will feature remote, flexible and on-demand work.

Some common myths as floated must be nullified-

- Industry 4.0 is applicable to only large corporate & Industries and requires significant upfront investments. This is completely wrong. SMEs too can opt for it based on their limited fund. What is required is mindset to change. We will discuss how it can be achieved with limited fund later in this article.

- Industry 4.0 will eliminate jobs and increase unemployment. Whereas the truth is it will increase employment with relevant skill. Employers seem to be happy with this wrong notion and I am often asked about this. But the truth is, it may reduce headcount but not the employment cost which either will be the same or increase. The difference Industry 4.0 will make is it will change the social status of Blue Collar workers by way of improving their income. They will be free from tiresome physical work. Let me recall the truth- Ever since Industrial Revolution in 1867, how many jobs have been made redundant so far? Only One – that is of Elevator due to safety reason. During 2000 when computerisation got prominence, there were huge call outs of job losses- from Banks, Govt Sector to Private sector. Did we see any job losses? None.

- Machine will take over humans. Wrong again. Machines are by human. Human is not by machine. World Economic Forum has recently clarified the myth by saying “The World will always need human brilliance, human ingenuity and human skill. Machines will supply us with insights & perspective we need to reach to solutions, but, machines won’t supply judgment or the ingenuity. People will”. Even some countries had started propagandizing to pay Waste/ Unemployment Allowance to their population! Is this is the way any economy functions? Will there be any customer to buy industrial product/s? Contrary is rather true. More the employment/income, more will be the demand of industrial product. I am sure citizens are not fool not to understand the gimmicks to suppress developing countries.

- The more Data Collected, the better. True. With this arises a common misconception that simply collecting data is enough, with better decision-making being supported through machine enabled data analytics. Mere enabling IIoT to collect huge data will never help. Machine has no ability to analyse these data and arrive at a decision. The challenges being faced by industries on daily basis are unique. No machine can be made capable of anticipating/apprehending such unique problems & challenges. Developing human intellectual capital with deep understanding of economic data and ability to analyse on various economic parameters and add value to operation is the key.

- Industry 4.0 will leverage opportunity to grow. Wrong. It can only facilitate. Without competencies and abilities organizations cannot grow. Technology can never help industries to run on its own.

Are we not capable of proving the myth wrong? Sure, we can by adding value to untold facts and the technology. India is known for its wisdom ever since ancient days. We are being watched closely of our strategies. Let us prove we can do.

Is Artificial Intelligence new?

So far as availability of products loaded with Artifical Intelligence is not new. For example-

- LG Electronics in 1998 launched a TV Model in the name of Golden Eye. The TV use to adjust its brightness, contrast & color based on light of the room.

- We have refrigerators with features of auto cut off after attaining required temperature.

- We have several electronic gadgets available in the market to operate without human intervention – auto start & auto shut.

- Process integration, automation and integrated plants are also there since long.

- ERP, a step towards data integration and analysis was implemented way back in 2000.

So what is new? The change lies in production process purportedly to improve productivity & lower manufacturing cost. In VUCA World given intense competition, every industry has to have competitive advantage- from product edge to cost, price and margin edge.

Nine Pillars of Industry 4.0

- IIoT- Industrial Internet of things is a network of intelligent computers, devices, and objects that collect and share huge amounts of data. The collected data is sent to a central Cloud-based service where it is aggregated with other data and then shared with end users in a helpful way. The IoT will increase automation in homes, schools, stores, and in many industries.

- Cloud Computing – It is a network of remote servers hosted on the Internet to store, manage, and process data, rather than a local server or a personal computer. Industries will have no control over the confidential data that can be accessed by any person.

- Robotics- Autonomous robots transfer raw materials, half-finished and completed goods in an easier, faster and smarter way. They operate based on a complex logic algorithm, meaning they don’t require any preset path to carry out their duties.

- Big Data & Data Analytics- Data collected from various sources and at different levels of manufacturing process can be made available for analysis and understanding the trend that helps in decision making process.

- Simulation- A simulation, in present day is used to design components that are manufactured. In Industry 4.0, it can be used to simulate a virtual environment of the factory itself with the real time data and analyze the productivity before a change in the factory can be made.

- Horizontal & Vertical Integration- An organization can be integrated vertically within the organization to capture the data from various activities and resources. It can also be integrated horizontally with the market to capture data from both supply side and and demand side to analyse the trend.

- Cyber Security – Cyber security becomes the talk of the town since the dawn of Information technology. The greatest nightmare of any information technology firm is having their server and data hacked. Preventing such a catastrophe and safeguarding the data and performance of the server is the sole purpose of cybersecurity.

- Augmented Reality – Augmented Reality based systems are storming the technology industry. Few years ago they found their applications only in flight simulators. Today remote repair instructions can be sent to literally any part of the earth with internet accessibility. It helps technicians to enhance their skills by practicing high end repairs and maintenance over and over again using augmented reality.

- Additive Manufacturing and 3D Printing- Companies are already using additive manufacturing techniques like 3D-Printing to make prototypes and Proof of concepts. The flexibility of Industry 4.0 allows us to design complex designs which are nearly impossible with conventional manufacturing processes.

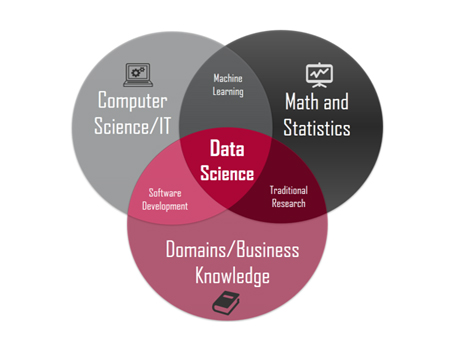

Data Scientist

The Profile of Data Scientists as suggested by global leaders-

Whereas, fact remains- No Leader can wear all the hat to claim he has due knowledge across all the domain/functions-Procurement, Production, HR, Industrial Engineering, Accounts & Finance etc. Till a years back, with no Data Scientists in the global market, a pay package of around US$ 205479 or INR 1.5 Cr was being offered. Still none could hire with required profile. Does such profile exist?

Pandemonium and Facts

Various negativist perspectives have been created purportedly either with lack of knowledge or to misguide developing countries. Several myths and false propaganda by global majors and global experts have failed to impress upontheir perspective. Efforts have been made to monopolise their offers and services to keep control over economies and economic entities. Efforts are still on to capture Information & Communication space by leading countries like China & US, but, the wisdom of Indian Govt is trying to save guard interest of Indian entities and have so far rejected the offer and the requests. General perspectives and high cost as projected have created big confusion within the country & the organizations to delay the project & transformation process that has best suited western organizations giving them enough space to capture the market.

As these waves of change continue to shape the competitive landscape, manufacturers must decide how and where to invest in new technologies and identify which ones will drive the most benefit for their organizations. In addition to accurately assessing their current strategic positions, successful manufacturers need a clear articulation of their business objectives, identifying where to play in newly emerging technology ecosystems, most importantly what are the technologies, both physical and digital, that they will deploy in pursuit of decisions they make about how to win.

Instead of being carried away by global general perspective, wisdom lies in contemplating and medition on information and knowledge creating new analytical role, not just investing in tools to information. It would be proper to distinguish between “Modelling Scientist” and “Decision Scientist” that help in achieving desired results to sustainability. Acquiring business wisdom to the cognitive content of “trenched business-building block” is obligatory to stay relevant.

Each & every organisation has its own dynamics. Varied product & process cannot have One-Size-Fit-All Solution as is being sold in the market. No better than you or your talent could understand the requirements of your organization.

Any investment in the technology has to be gradual. Assessing the business dynamics and the requirement should be the prime factor. Most of the organizations may be having some degree of automation in their plant & machines.

Of Nine Pillars, Cloud Computing has been included to take control of economies by way of accessing their confidential data. The service is offered by few countries through servers at their countries. By way of availing the service, economic entities will have no control over their economic data. This will be subject to laws of the country having server in their control. Compromising with confidential data that is preserved only for a specific period as per their governing laws is certainly not advisable. Mis-utilisation of data cannot be ruled out. Govt of India has been suggested to create cloud computing of its own which hopefully will be rolled out after launch of 5G Spectrum.

The Real Game Changing Perspective

Industry 4.0 is a vision that evolved from an initiative to make the German manufacturing industry more competitive (‘Industrie 4.0’) to a globally adopted term. Industry 4.0 is a vision and concept in motion, with reference architectures, standardization and even definitions in flux.

The goal is to enable autonomous decision-making processes, monitor assets and processes in real-time, and enables equally real-time connected value creation networks through early involvement of stakeholders, and vertical and horizontal integration.

Industry 4.0 is the information-intensive transformation of manufacturing (and related industries) in a connected environment of big data, people, processes, services, systems and IoT-enabled industrial assets with the generation, leverage and utilization of actionable data and information as a way and means to realize smart industry and ecosystems of industrial innovation and collaboration.

Industry 4.0 is not ‘something’ you realize overnight. Just as is the case with IoT deployments you need a strategic and staged approach. Industry 4.0 builds upon data models and data mapping across the mentioned end-to-end product life cycle and value stream. All the technologies in Industry 4.0 need to be seen in that perspective whereby integration is key.

Without Information Technology and Operational Technology convergence there is no industrial transformation, let alone modern building management and several other areas where the silos between different traditional systems disappear due to, among others, IoT on one hand and where IT and OT meet on the other, which is the case in close to all industries. The essence of IT and OT convergence revolves around data (and the systems where they have been sitting for many years), processes and people/teams. Again, the IoT is key here as also the Internet of Things starts with the capture (and subsequent analyses/leverage of data). It is safe to say that Industry 4.0 is only possible because of IoT.

Organisations have to move on from Managing Performance to Enabling Performance. Management is about managing something that exists. But what about macroeconomic challenges that keeps on changing on daily basis and that which does not exist?

How Industry 4.0 Works

Developing understanding of Industry 4.0 and how it works will enable industries to save huge cost.

Industry 4.0 is said to improve Productivity, purportedly by increasing output by automation and without human intervention. It will help in predictive & generate simulation for proactive, predictive & remote maintenance of the machine to reduce machine breakdown & downtime.

Understanding the purpose of Industry 4.0 is an essence

While digitization is inevitable to enable fast decision-making process, productivity cannot be improved by increasing the output alone. Output will have its limitation depending upon plant capacity and market demand. Any increase in production will be bound by economic principles- Law of Diminishing Margin. As such, overall organizational productivity, or, Total Factor Productivity or Multi-Factor Productivity will never improve to impact the bottom line enduring growth.

To have better understanding, it is essential to quote the survey findings of Enno de Boer, Partner & Global Manufacturing Head, McKinsey & Co as reported by World Economic Forum in early 2019 that states- “These pioneers have created factories that have 20 to 50% higher performance and create a competitive edge. They have agile teams with domain, analytics, IoT and software development expertise that are rapidly innovating on the shop floor. They have deployed a common data/IoT platform and have up to 15 use cases in action. They are thinking scale, acting agile and resetting the benchmark.”

This proves two things-

- No global management consultant is sure about how to utilize the technology.

- The technology is more about improving operational efficiency to reduce cost than technological advancement.

The technology has been left to organizations to fend their ways as to how to utilize to their benefit.

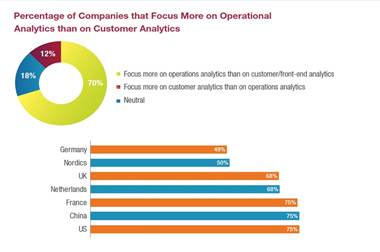

Capegemini in 2016 has published a survey report to state more than 70% of global organizations have shifted their focus from Customer Analytics to Operational Analytics.

The business equation of pre-globalization era where Industries had the liberty to determine the profit is no more. In VUCA World given the FTA rules intense competition has changed the business equation.

Profit = Sales – Manufacturing Cost

Modern theories of firm strategy integrating various analytics has yielded little to no result. Lean philosophy designed by Toyota Motors, Japan based on their own culture being copied by other countries too has not improved the bottom line. Lean must be tailor made based on value stream mapping which is ever changing. General notion of growing scaling sales revenue has lost its sheen. Profit is now incidental to operation. However, growing business complexities and disruption is the biggest organizational dilemma. Growth is now directly proportionate to shrinking leadership ability. Sales may generate revenue but cannot improve the bottom line and ensure growth.

For example, each and every unit we produce caries equal amount of profit. But profit never commensurate change in sales.

The purpose of Industry 4.0 is more about being cost-efficient and competitive through Business Analysis, Business Intelligence, Decision Intelligence and Operational Analytics than technological advancement. Right use of the technology is the essence.

The Freezes

My discussion with several CEOs reveals organizations have no idea how Industry 4.0 works. Survey by PwC in the month of Dec’19 / Jan’20 reveals more than 90% of CXOs have no idea about requirement of Industry 4.0 and risks associated with it. Purportedly, this may be the attribute of chaotic situation created and lack of clarity. Over specification and host of tools on recommendation may have created confusion.

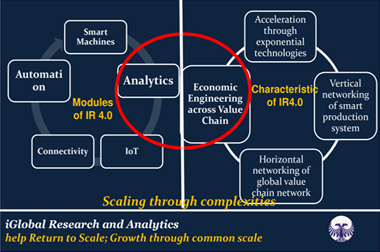

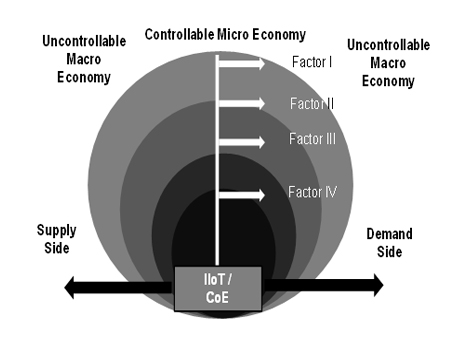

Close look at below infographic may help readers to understand how Industry 4.0 works and how to derive benefits from it in controlling the factors of production/operation while integrating the organization vertically & horizontally.

One of the renowned industry into automobiles has initiated adopting Industry 4.0 in their Tamilnadu plant recently and engaged renowned tech consultant. Just for one of the tool i.e IIoT and software they charged Rs 5.0 Cr but the work has to stop halfway due to their inability to connect with machine. The organisation has to engage yet another automation industry for fixing sensors and machine learning that is costing them yet another Rs 5.0 Cr. Discussion with their CXOs revealed they have no idea of Industry 4.0. They do not have any idea how it works and what they will do with the technology / how they will utilise it and what are the benefits.

Lack of awareness is certain to put the investments at risk. Before deciding on shifting to new normal that is inevitable now for resiliency & to remain relevant we must consider developing in-house capabilities. Technology has already been adopted by most of the organisations internationally and is occupying the business space fast. With complete knowledge of Industry 4.0 and about its performance pillar, Industries can substantially reduce their investment and do away their dependence on any tech consultant and/or automation industries. Depending upon them will fetch recurring cost towards maintenance. So better to develop in-house and save huge cost.

Provided further, creating Centre of Excellence is a must. I re-iterate technology cannot run the industry, it can only facilitate. The CoE comprises of Decision Scientists from respective domains with ability to read operational economic fine prints. They must have robust analytical skill to analyse the data from various economic parameters.

The Performance Pillar of Industry 4.0

Industry 4.0 heralds profound and rapid change. This is a time of great challenges and opportunities. Provided further Coronavirus and Chinese excesses have created much of Business space both in domestic and international market. This is evident from the fact that country’s export has surged by 5.27% to USD 27.4 Billions in Sept’20 as compared to last year. The Purchasing Manager Index (PMI) has touched 56.8, the highest in 8 years. The rapidly growing economies of South-East Asia are particularly well placed to thrive in this new world. At a rate of expansion and urbanization, given the population growth, changes in consumption are helping to drive rapid growth of ASEAN countries.

The rate of expansion is difficult to conceptualize, regions labour force is forecast to grow by 11,000 workers every day for the next 15 years. This comes at a time when the workplace is undergoing radical change with artificial intelligence (AI), automation and the Internet of Things (IoT) transforming how we do business.

Technology by itself is not the disruptor, not having the right skill is. Mere digitalisation for vertical and horizontal integration of businesses/organisation deploying Cyber Physical Assets or tools of AI will not help. Deriving benefit for cost optimization across operational segment will help organisations taking forward their businesses to whole new level of sustainable paradigm in VUCA & disruptive world.

Having a workforce with the right skills is central to achieving sustainable growth. To make the best of the opportunities presented by new technology, White Collars & Blue Collars need to be upskilled with Performance Pillar relevant to the technology. Employers and policy-makers need to commit to investing in training and development so that the workforce is ready for more complex roles.

Fundamentals of Business & Operation can never change with any technology. The gravity increases with the competition to remain relevant.

Every Business has its own dynamics based on its governing Socio-Politico-Demographic-Economic limitations and operational challenges. There cannot be One-Size-Fit-All formula to generalise and offer solution by any consultant through either software or hardware. No one better than you and your employees are aware of such challenges. No one other than you can resolve the operational problems being faced by your organization. Industries have to read, imagine & restructure their own Structure and Drivers of Production/Operation to decide upon their own requirement.

The irony is Industries never measure Inclusive Wealth Index that helps negotiate the gap. Deriving tool of value addition across wealth index alongside revenue generation across operation will lead to overall growth of economic entities both on macro level and micro level.

Economic Engineering & Econometrics to add value across value chain of dynamics of supply chain is the only Performance Pillar and Business skill that has replaced conventional skill of 19th & 20th century. 21st Century Business perspective is mandatory for being cost-efficient & competitive to occupy business space both in domestic and international market.

Economic Engineering and Econometrics is the subset of Economic and Operational theory encompassing Operational Research, Business Economics & Industrial Engineering to deal with the behaviour of all the resources, inter-alia, factors of operation/production for optimum allocation and utilization of resources in use through simple mathematics & statistics to control & determine cost on real-time basis, as also, to neutralize macro economic implications at micro level of operation. It improves productivity of all the resources in use.

Manufacturing is more than assembly of parts or preparing input basket for a new and value added product. It encompasses dealing with various factors governed by its own dynamics to synchronize for common scale growth. Return to scale addressing diseconomies is a complex problem that is often overlooked by leaders.

Imagine,

- A retailer selling your product earns more than you!

- Why take so much of botheration- meeting labor laws, tax laws etc when your bank can give you same return!

- All your effort to reduce or save cost, clocks-off, leaving you wonder where all the money gone!

- Why return on cost of capital employed is so low?

Underperformance conundrum still haunts industries that call for holistic approach to analyse the business from all the economic parameters for being cost-efficient with competitive advantage. Your unit is capable of higher return provided you work with fundamentals of Business & Operation. The efficiency of Productivity Analysis increases with the availability of data from various sources. This has now been ensured by Industry 4.0.

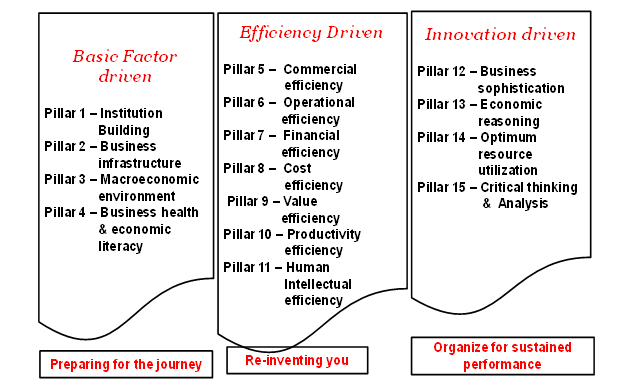

Industries need to draw global competitive model as under based on following pillars-

Developing competencies and capabilities creating new analytical role across functions, and, building organizational Performance Pillar relevant to technology is the first step towards new normal. Selection of tools of AI has to be based on availability of such capabilities. This will enable-

- Identify reliable source of data

- Know what to do with huge data

- On what operational economic parameters data need to be analysed

- Control & synchronize factors of production/operation for optimum utilisation & cost.

- Improve organizational performance

- Be cost efficient & competitive

Eventually…

Business is no more limited to conventional norm of selective improvement. A transformation is not a series of incremental changes, it is a fundamental reboot. It has to represent a fundamental and risk laden reboot of a company with a goal of achieving dramatic improvement in performance and altering its future trajectory. John Hitch, Senior Technologist at Industry Week has said “Manufacturers are often content with incremental improvements in time, accuracy and quality. As long as you’re “continuously improving,” you’re on the path for success. However, due to AI, in few years the current incremental changes catalyzed by Kaizen and Lean Manufacturing might look like absolutely pedestrian.…… In this new era of engagement, reasoning and judgment are at the forefront. For the C-suite, this has never been easier. As the vertical integration of machine learning continues, ERPs and CRMs, the front and backend, it’s all connected, allowing decision makers to recognize patterns and trends they can act on.

Fourth Industrial Revolution & AI is a reality now. The sooner we get on board, the better for us to stay relevant. You don’t need a PhD to start playing with AI. You just need to get your hands dirty. AI is a team effort. It’s not about a specific technical background, but about being part of it. It’s about embracing AI to achieve augmented intelligence……. But nothing is a given, nothing is a guarantee. You need the right people with right skill, the right value proposition, and the right technology to propel your business, and may be even your industry, into the future.

Simultaneously, you need to avoid financial risk avoiding huge investment in a technology that can be built in-house. Building Performance Pillar, developing competencies & capabilities you can –

- Save 90 % of AI Project estimated standard cost of about Rs 10-15 Cr (for one unit of medium size entity)

- Reduce 20-30% Operational Cost on recurring basis

- Improving connectivity, you can improve your global reach

Assessing the competency gap & developing capabilities of the team rolling out HR 4.0 initiative is the first step towards migration to new normal.

“Opportunities don’t happen. You need to create them” – Chris Grosser

Business is not a value. Business value is a model.Business Value Model what we Value.

About the Author:

Mr. Manoj Trivedi has four decade leadership across diverse industries of repute. Presently he is the Director & Business Mentor of iGlobal Research and Analytics founded by him to help manufacturing organizations, Business Leaders & CXOs to grow with 21st century business perspective. Being the author of three e-books available at Kindle & Google Play Book Store, his expertise has been retained by- (a) Consortium appointed by Govt of UK & EU to develop industries across ASEAN & African countries (b) NSIC Ltd (c) MSME-DI, Kolkata, DC, Ministry of MSME Govt of India to name a few.

He can be reached at (91) 9051831961, or, [email protected]. He also offers customized distant learning program on one to one basis during Corona Virus period and as stop gap measure to interested leader/s.

Also read my earlier articles