Industry 4.0 : Principles,Technologies,Advant

to Overcome!

Industry 4.0, also known as the Fourth Industrial Revolution, represents a significant transformation in the world of manufacturing and industry. It is characterized by the integration of digital technologies into industrial processes with the primary aim of improving manufacturing responsiveness, quality, and efficiency. This revolution is reshaping the landscape of manufacturing, enabling companies to achieve higher levels of productivity, flexibility, and self-managing production processes. In this essay, we will explore the key principles, technologies, and advantages of Industry 4.0, as well as its applicability across various industrial segments.

Principles of Industry 4.0

At the core of Industry 4.0 are several key principles that define its approach to manufacturing and industrial processes. These principles serve as guiding philosophies for the implementation of digital technologies in the industrial sector:

- Interoperability:

Interoperability emphasizes the seamless communication and integration of various components within a manufacturing ecosystem. In an Industry 4.0 environment, different machines, sensors, and systems can work together effectively, sharing data and information in real-time. This interconnectedness enables the efficient flow of data and decision-making.

- Virtualization:

Virtualization involves the creation of virtual models or digital twins of physical assets and processes. These digital replicas provide a means to simulate and analyze real-world scenarios, allowing for optimization, testing, and troubleshooting without disrupting actual operations. Digital twins are instrumental in predictive maintenance and process improvement.

- Decentralization:

Industry 4.0 promotes decentralization by empowering individual components and devices with decision-making capabilities. Rather than relying solely on centralized control, smart machines, and systems have the autonomy to make real-time decisions based on data and predefined rules. This decentralization leads to increased flexibility and adaptability in manufacturing.

- Real-Time Capability:

Real-time capability is a fundamental aspect of Industry 4.0, enabling the immediate processing and utilization of data. In a manufacturing setting, real-time data analysis ensures rapid response to changing conditions, such as production anomalies or shifts in customer demand. It supports agile decision-making and optimization.

- Service Orientation:

The service-oriented approach in Industry 4.0 extends beyond physical production to include value-added services. Manufacturers can offer customized services alongside their products, creating new revenue streams and enhancing customer experiences. This shift towards servitization is a hallmark of Industry 4.0.

Modularity:

Modularity refers to the design of systems and processes in a way that allows for easy integration, modification, and scalability. Modular systems facilitate the replacement or addition of components without extensive disruption, promoting efficiency and flexibility in manufacturing environments.

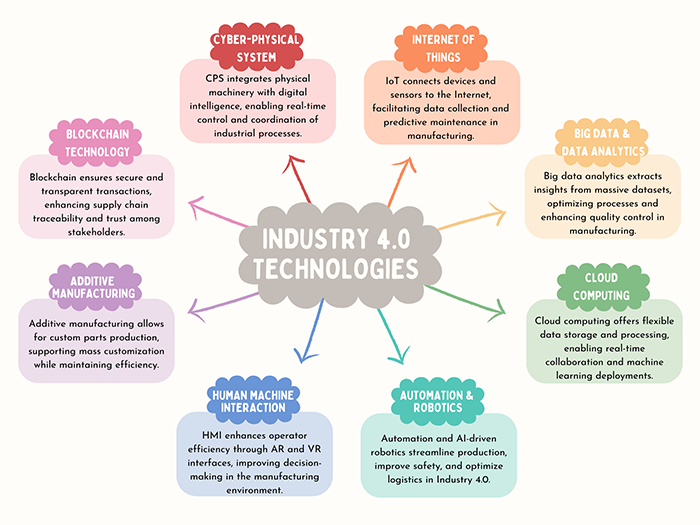

Technologies Driving Industry 4.0

Industry 4.0 leverages a range of advanced technologies to bring its principles to life. Some of the key technologies include:

- Cyber-Physical Systems (CPS):

At the heart of Industry 4.0, CPS combines physical machinery with digital intelligence. These systems enable real-time monitoring, control, and coordination of physical processes. For instance, a smart factory may employ CPS to optimize production and maintenance processes.

- Internet of Things (IoT):

IoT connects devices and sensors to the Internet, facilitating data collection and sharing. In manufacturing, IoT enables predictive maintenance, remote monitoring, and efficient resource utilization. Sensors placed on machinery can transmit data for analysis and decision-making.

- Big Data and Data Analytics:

The vast amounts of data generated by IoT devices and other sources require advanced analytics to derive meaningful insights. Big data analytics identifies patterns, anomalies, and opportunities for improvement. Manufacturers can use these insights for quality control, demand forecasting, and process optimization.

- Cloud Computing:

Cloud computing provides a scalable and flexible infrastructure for data storage and processing. It supports remote access and collaboration, making it possible for geographically dispersed teams to work together in real-time. Cloud platforms also facilitate the deployment of machine learning models and data sharing.

- Automation and Robotics:

Automation in Industry 4.0 involves the use of robots and artificial intelligence (AI) to automate tasks and processes. Robots can handle repetitive and dangerous tasks, while AI algorithms can optimize production, inventory management, and logistics.

- Human-Machine Interaction (HMI):

HMI focuses on improving the interaction between humans and machines within the manufacturing environment. Augmented reality (AR) and virtual reality (VR) interfaces enhance operator efficiency and decision-making.

- Additive Manufacturing (3D Printing):

Additive manufacturing technologies allow for the creation of complex, customized parts and prototypes. This contributes to the concept of mass customization, where products are tailored to individual customer needs without sacrificing efficiency.

- Blockchain Technology:

Blockchain provides a secure and transparent way to record and verify transactions. In supply chain management, it ensures traceability and authenticity of products, reducing the risk of counterfeit goods and enhancing trust among stakeholders.

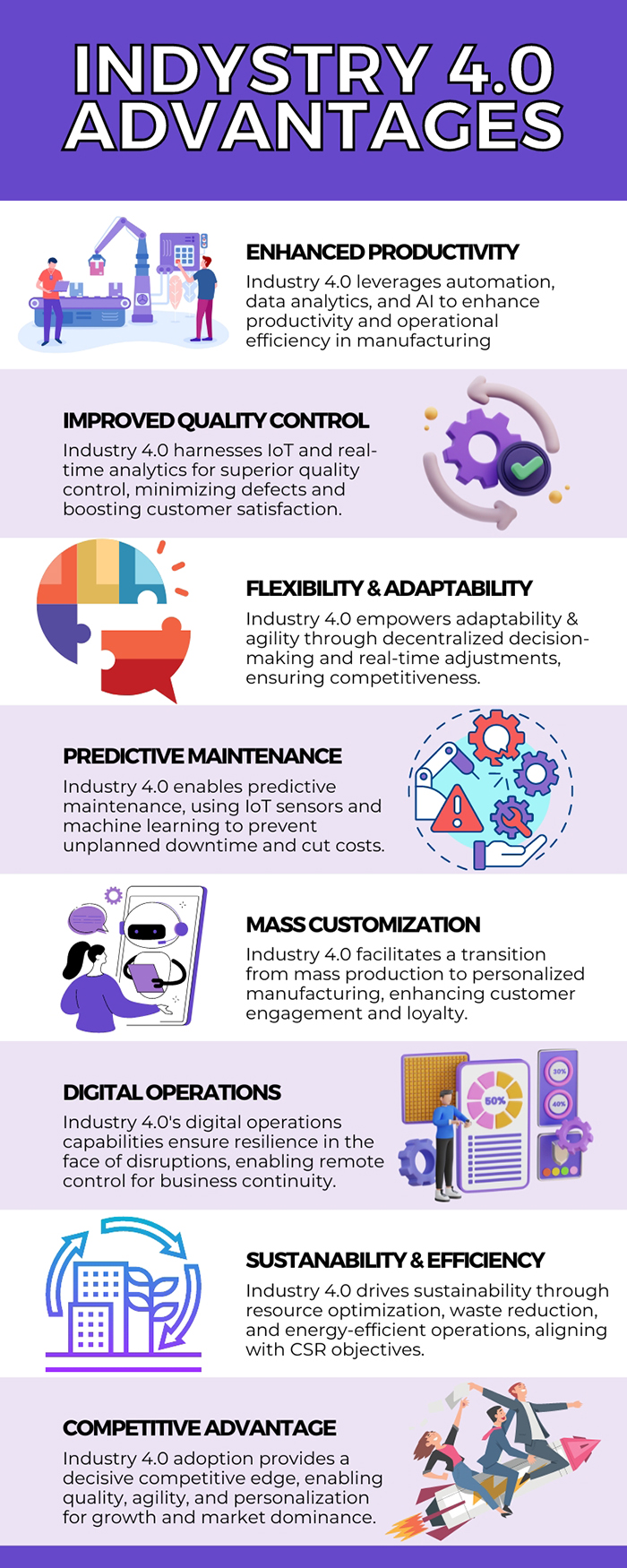

Advantages of Industry 4.0

The adoption of Industry 4.0 technologies offers numerous advantages to industrial companies, especially amid the challenges presented by events like the COVID-19 pandemic. Here are some of the key benefits:

- Enhanced Productivity:

One of the most significant advantages of Industry 4.0 is the substantial increase in productivity and operational efficiency it brings to manufacturing and industrial processes. Through the integration of advanced technologies such as automation, data analytics, and artificial intelligence, production processes become streamlined and optimized. Real-time monitoring, predictive maintenance, and autonomous systems lead to reduced downtime, higher throughput, and improved resource utilization. This enhanced productivity ultimately translates into cost savings and increased competitiveness for businesses.

- Improved Quality Control:

Industry 4.0 technologies provide unprecedented capabilities for quality control and assurance. IoT sensors and real-time data analytics enable manufacturers to detect defects and anomalies in products or processes immediately. This allows for timely adjustments, reducing the production of faulty goods and enhancing overall product quality. As a result, companies can maintain higher customer satisfaction levels and reduce costs associated with rework or recalls.

- Flexibility and Adaptability:

In a rapidly changing business landscape, flexibility and adaptability are crucial. Industry 4.0 promotes these attributes by decentralizing decision-making and enabling quick responses to market fluctuations and customer demands. Smart manufacturing systems can adjust production schedules, product configurations, and resource allocations in real time. This flexibility not only improves agility but also helps businesses remain competitive in dynamic markets.

- Predictive Maintenance:

The implementation of Industry 4.0 allows for predictive maintenance strategies. By continuously monitoring the condition of machinery and equipment through IoT sensors and analyzing data with machine learning algorithms, companies can anticipate when maintenance is needed before equipment failure occurs. This proactive approach minimizes unplanned downtime, reduces maintenance costs, and extends the lifespan of assets.

- Mass Customization:

Industry 4.0 enables a shift from mass production to mass customization. Through technologies like additive manufacturing (3D printing) and advanced robotics, companies can efficiently produce personalized products tailored to individual customer preferences. This not only meets the growing demand for personalized goods but also fosters stronger customer engagement and loyalty.

- Digital Operations:

The ongoing digital transformation in Industry 4.0 has proven invaluable during unexpected disruptions, such as the COVID-19 pandemic. With remote monitoring and control capabilities, manufacturers can continue operations even when physical presence is limited. This resilience enhances business continuity and minimizes the impact of crises, ensuring that production can continue without compromising safety.

- Sustainability and Resource Efficiency:

Industry 4.0 technologies contribute to sustainability efforts by optimizing resource utilization and reducing waste. Predictive analytics and process optimization lead to more energy-efficient operations, reduced material waste, and minimized environmental impact. This not only aligns with corporate social responsibility goals but also reduces operational costs in the long run.

- Competitive Advantage:

By embracing Industry 4.0, companies gain a significant competitive advantage. They can deliver higher-quality products, respond faster to market changes, and offer personalized solutions that meet customer demands effectively. This enhanced competitiveness can lead to increased market share, revenue growth, and a stronger market position in their respective industries.

Applicability Across Industries

The transformation brought about by Industry 4.0 is not limited to a particular sector. It is applicable across various industrial segments, including manufacturing, aerospace, food, energy, mining, and healthcare. Let’s explore its applicability in a few key sectors:

- Oil and Gas Industry:

The oil and gas sector has adopted Industry 4.0 to enhance exploration, drilling, and production processes. IoT sensors on offshore platforms monitor equipment health and environmental conditions, while predictive maintenance ensures the reliability of critical machinery.

- Mining Industry:

Mining companies leverage Industry 4.0 to optimize resource extraction, reduce operational costs, and enhance worker safety. Autonomous mining equipment, equipped with sensors and AI, can operate in hazardous environments, making operations more efficient and less risky.

- Healthcare:

In healthcare, Industry 4.0 technologies are used to improve patient care and streamline hospital operations. IoT devices and wearable sensors enable remote patient monitoring, while data analytics support disease diagnosis and treatment planning.

- Additive Manufacturing (3D Printing):

Industry 4.0 technologies have revolutionized additive manufacturing processes, allowing for the creation of complex and customized products. 3D printing, supported by digital design and real-time monitoring, enables rapid prototyping, reduced material waste, and on-demand production of parts and products.

- Aerospace and Defense:

The aerospace and defense sector uses Industry 4.0 to improve aircraft manufacturing, maintenance, and operations. IoT sensors and data analytics help optimize aircraft performance, reduce fuel consumption, and enhance safety.

- Food and Beverage:

Industry 4.0 is used in the food and beverage industry to monitor and control production processes, ensuring food safety and quality. Automated systems and sensors help with inventory management, production scheduling, and traceability.

- Energy and Utilities:

The energy and utilities sector employs Industry 4.0 technologies to manage power generation, distribution, and consumption more efficiently. Smart grids, sensors, and real-time data analysis enable better energy management and grid reliability.

- Pharmaceuticals:

Pharmaceutical companies utilize Industry 4.0 to improve drug development, manufacturing, and quality control. Automated processes, robotics, and data analytics enhance the production of pharmaceuticals while ensuring compliance with regulatory standards.

- Retail and E-commerce:

Retailers and e-commerce companies leverage Industry 4.0 for supply chain optimization, inventory management, and customer personalization. RFID technology, AI-driven demand forecasting, and automated warehouses are some examples of its application.

- Logistics and Transportation:

The logistics and transportation industry utilizes Industry 4.0 to optimize routes, track shipments, and improve overall logistics efficiency. IoT-enabled tracking devices, autonomous vehicles, and predictive maintenance play significant roles in this sector.

- Agriculture:

Precision agriculture employs Industry 4.0 technologies to enhance crop management, optimize resource usage, and monitor environmental conditions. Sensors, drones, and data analytics assist farmers in making informed decisions to increase yield and sustainability.

- Textiles and Apparel:

Textile and apparel manufacturers benefit from Industry 4.0 by automating production processes, reducing waste, and enabling customization. IoT devices and digital twins help monitor and control textile production lines.

- Construction and Real Estate:

In construction, Industry 4.0 aids in project management, building design, and maintenance. Building information modeling (BIM) and IoT sensors improve construction efficiency and building performance.

- Financial Services:

The financial industry incorporates Industry 4.0 technologies for fraud detection, risk assessment, and customer service. Machine learning algorithms and data analytics are used to analyze financial data and make informed decisions.

Challenges of Industry 4.0 Adoption

While the promise of increased efficiency, productivity, and competitiveness is alluring, the adoption of Industry 4.0 technologies presents several challenges that must be addressed strategically. We will explore the key challenges associated with Industry 4.0 adoption.

- Lack of Internal Alignment:

One of the foremost challenges faced by businesses when embracing Industry 4.0 is the lack of internal alignment regarding which strategies to pursue. With the advent of digital technologies, new business models are emerging, necessitating a shift in how companies operate. However, without a consensus on the business strategy, or the right people in place to drive it, internal challenges can impede progress.

- Cybersecurity and Data Privacy Concerns:

As businesses become more interconnected through Industry 4.0, there is a heightened concern for cybersecurity and data privacy. The online integration of processes, systems, and people creates vulnerabilities that can be exploited by cyberattacks, potentially resulting in security breaches and data leaks. Companies must make substantial investments in advanced encryption, authentication protocols, and robust cybersecurity measures to safeguard critical information generated by connected devices and systems.

- Workforce Displacement:

Automation, a key component of Industry 4.0, can lead to concerns about workforce displacement. As machines and algorithms take on more tasks, the nature of work may change, potentially displacing some workers. This challenge requires companies to address the impact on their employees through reskilling and upskilling initiatives to ensure a smooth transition to new roles and responsibilities.

- Technology Adoption Pathways:

The path to Industry 4.0 adoption varies significantly based on the specific technologies being incorporated and the existing infrastructure and skills of organizations. For some, the transition may involve significant changes and investments, while others may find a more gradual approach suitable. Navigating these pathways can be complex and challenging.

Strategies to Overcome Industry 4.0 Challenges

To harness the power of this transformative era, companies must navigate these challenges effectively. Given below are strategies to overcome the adoption challenges.

- Comprehensive Understanding of Capabilities:

To address the lack of internal alignment, businesses should start with a comprehensive understanding of their current capabilities. This involves assessing the skills, resources, and technologies already in place. Identifying the gaps that Industry 4.0 can fill is crucial. This assessment may reveal the need for reskilling or upskilling initiatives to ensure that the workforce is prepared for the technological shift.

- Addressing Cybersecurity Concerns:

Prioritizing cybersecurity is non-negotiable in the age of Industry 4.0. To mitigate cybersecurity and data privacy concerns, companies must make substantial investments in advanced security measures. This includes implementing robust encryption, multi-factor authentication, intrusion detection systems, and regular security audits. Moreover, fostering a cybersecurity-aware culture within the organization is equally important to ensure that employees are vigilant and informed.

- Change Management Strategies:

Effective change management is pivotal in overcoming resistance and driving acceptance of new technologies. Collaborative efforts to manage change within the organization can help address the challenges associated with Industry 4.0 adoption. This involves clear communication of the reasons for the changes, providing training and support to employees, and involving them in the decision-making process where possible. Engaging leadership and leading from the top can play an important role in bringing about the cultural change needed for digital transformation.

- Scalability and Flexibility:

Industry 4.0 solutions must be scalable and flexible to adapt to changing demands and future growth. Companies should design solutions that are agile and can evolve with their business needs. It’s advisable to start with smaller, scalable pilot projects that can demonstrate the value of Industry 4.0 technologies before committing to larger-scale implementations. This allows businesses to learn, iterate, and scale gradually.

- End-to-End Approach:

Successful implementation of Industry 4.0 technologies requires an end-to-end approach that incorporates people, processes, technologies, and data. Rather than viewing technology adoption in isolation, businesses should consider how it fits into their overall operations and strategy. This holistic approach ensures that technology is integrated seamlessly, and its benefits are maximized.

Conclusion

Industry 4.0 represents a pivotal transformation in the industrial landscape, driven by the seamless integration of digital technologies into manufacturing and industrial processes. Its foundational principles of interoperability, virtualization, decentralization, real-time capability, service orientation, and modularity serve as guiding pillars for the adoption of cutting-edge technologies like Cyber-Physical Systems, the Internet of Things (IoT), extensive data analytics, and automation. Embracing Industry 4.0 yields numerous advantages, including heightened productivity, superior quality control, enhanced flexibility, and the agility to respond to dynamic market conditions.

Moreover, the COVID-19 pandemic has expedited the uptake of Industry 4.0 technologies, as they facilitate digital operations and contactless processes. This transformative shift extends beyond a specific industry; it has wide-ranging applicability across sectors, spanning from discrete manufacturing to healthcare.

In the ongoing progression of the Fourth Industrial Revolution, it becomes imperative for businesses to wholeheartedly adopt Industry 4.0 and leverage its capabilities to maintain competitiveness, efficiency, and adaptability within an ever-evolving global marketplace. The principles and technologies underpinning Industry 4.0 are shaping the future of industry, enabling a more interconnected, efficient, and sustainable approach to manufacturing and production.

Although the challenges associated with Industry 4.0 adoption are substantial, they are by no means insurmountable. Companies that strategically and proactively address these challenges can unlock the full potential of the Fourth Industrial Revolution. By gaining a deep understanding of their own capabilities, prioritizing cybersecurity measures, adeptly managing the process of change, and embracing scalable solutions through a comprehensive approach, organizations can successfully navigate the intricacies of Industry 4.0, positioning themselves for a future that is marked by efficiency, competitiveness, and digital transformation.

About the Author:

Mr. Deep Manishkumar Dave

Specialist Industrial IoT Engineer | Technology Consultant

LTIMindtree Limited,

![]()

Raynham, Massachusetts, United States.

Mr. Deep Dave is an accomplished Specialist Industrial IoT Engineer and a distinguished member of the Intelligent Automation Congress (IAC) and the Institution of Engineering and Technology

Mr. Deep Dave extensive experience and expertise make him a valuable asset to any discussion in the field. Furthermore, his recognition as a LinkedIn Community Top Voice in multiple crucial domains, such as Artificial Intelligence, Information Technology, Cloud Computing, Digital Transformation, Healthcare Management, and Blockchain, underscores his unwavering dedication to remaining at the forefront of emerging technologies.

With an impressive track record spanning over five years as a Specialist Industrial IoT Engineer at LTIMindtree Limited, Mr. Deep Dave have been instrumental in driving digital transformation and Industrial Internet of Things (IIoT) initiatives across both the manufacturing and healthcare sectors.

Mr. Deep Dave ability to provide valuable insights to authors and contribute significantly to the review process is a testament to his expertise.

Mr. Deep Dave academic background includes a B.Tech in Mechatronics Engineering and an M.Sc. in Engineering Management. These qualifications, combined with hands-on experience in deploying advanced technologies such as Artificial Intelligence (AI), Machine Learning (ML), automation, sensors, and analytics platforms, have enriched his foundational knowledge.

Mr. Deep Dave unwavering commitment to continuous learning and staying updated on the latest industry trends is evident in his dedication to ongoing reading, research, and scholarly contributions.

As a dedicated member of the IEEE and with Mr. Deep Dave extensive experience in the healthcare and medical device life science sector, he possess a profound understanding of the intricate relationship between digital transformation and industrial automation. My expertise lies in crafting comprehensive digital strategies that optimize business processes, leading to exceptional outcomes in this dynamic sector.

Mr. Deep Dave is bestowed with following Licenses & Certifications :

https://www.linkedin.com/in/de

Mr. Deep Dave can be contacted at :

E-mail | LinkedIn | Web

Also read Mr. Deep Dave’s earlier article :