Designing and Developing a Digital Twin: Considerations for Successful Implementation

Introduction

Advancements in technologies are enabling enterprises across the sectors to take notice and embrace them to solve business challenges and drive productivity to stay competitive. These technologies have led the way towards Industry 4.0 (a.k.a) Fourth Industrial Revolution which is a suite of next generation technologies that help solving business challenges and help enterprises become future ready.

Smart manufacturing is a technology-driven approach to optimize all aspects of the manufacturing process using data as the main driver. It uses Industrial Internet of Things (IIoT) to collect, cleanse, store and process data that is generated at each step of the manufacturing process. The data is generated by the process that is being followed, the physical assets involved in manufacturing and even by people who are monitoring and managing the whole process.

A smart system consists of self-aware objects/components with embedded sensors and communicate with each other over a secure network. The data is collected and typically stored in the cloud and can be fed to a digital framework that accurately corresponds to the physical ecosystem described above.

Such a framework or a Digital Twin of the physical realm can be designed to analyse / monitor / diagnose / rectify any anomaly in it. Advanced predictive and prescriptive capabilities based on learning models can pre-empt failures and anticipate unscheduled downtime.

Multiple aspects need to be considered while designing a “Digital Twin”, like its complexity level, physical models (aerodynamics, thermodynamics etc.) it will adhere to and its main functionality. I will address these points in subsequent sections.

What is a Digital Twin?

Let us start with a basic understanding of the concept. A digital twin or DT is a virtual representation that serves as the real time digital counterpart of physical assets/processes such as jet engines, wind turbines, factory floor operations and even whole cities or buildings. Physical object and its virtual counterpart or digital twin is interconnected with a high level of synchronization and interact in a mutually beneficial manner. A real-time data exchange allows continuous update of status information to the virtual object.

The gathered information can then be used to assess operating condition of the physical object, analyse historical data to predict maintenance requirements to avoid unscheduled downtime and monitor its condition by processing sensor data generated in real time.

Advancements in Machine Learning and big data technologies enable these digital models to showcase how corresponding physical systems would respond under a given set of operational scenarios. It helps to identify and prevent costly failures, enhance predictive capabilities, and optimize physical operations.

Another characteristic of DT is that these technologies leave digital traces. These traces can be used by engineers for example, when a machine malfunctions, to go back and check the traces of the digital twin, to diagnose where the problem occurred. These diagnoses can in the future also be used by the manufacturer of these machines, to improve their designs so that these same malfunctions will occur less often in the future.

What are the benefits of using a Digital Twin?

- Remote monitoring in real time – critical parameters of valuable assets can be monitored in real time for any anomalies and to optimize its performance.

- Predictive maintenance – large amounts of data is generated through the physical asset sensors which is then analysed for any pattern to identify problems in the system proactively.

- Rapid assessment – Engineers can test different operating models for their asset, simulate and test scenarios before deploying it on physical systems.

- Analysis of operational history – Pattern finding in the past data or digital traces can help to predict similar outcomes in future and can be planned well in advance.

What is different this time?

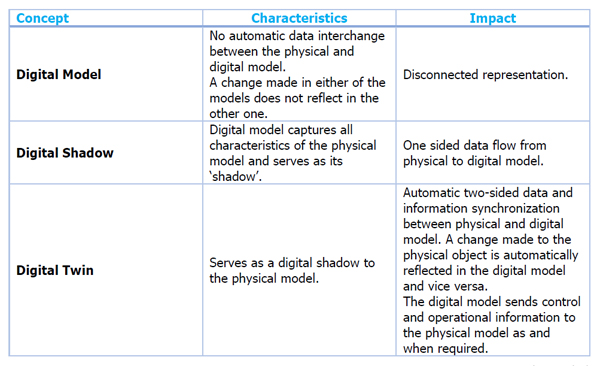

The concept of Digital Twin is not new. There are different avatars of digital representations of physical objects that have been actively used for a long time. Digital models developed using CAD accurately capture dimensional details and tolerance bands of the object to be constructed. Simulation software use mathematical representation of universal principles of Physics like thermodynamics, computational fluid dynamics to simulate situations and see how the proposed object would behave. Data historians store time series data generated by the process monitoring systems that can be analysed further to improve operational performance.

One big difference between these technologies and digital twin is the real time synchronization of data between the physical object and its digital model through an interconnected network of Internet of Things (IoT). Hundreds of sensors gather data on different operational and physical parameters, edge devices process the information before sending it to the cloud for digital twin to update its status and remain in sync with the exact state of the physical object. The main difference between these technologies is the interaction and exchange of data between the physical object and the digital model. I will describe further to help you understand better.

On the prediction front, the major difference between a digital twin and a simulation is that the former has a two-way data interconnection with the physical model and uses the current and historic data to make predictions on the system behaviour, while simulation predicts the future state of a physical system based on a set of assumptions and its own dataset. It does not consider the real data captured from the very same physical object it is predicting about. A digital twin plugs this gap and make predictions with far more accuracy.

Simulation models can complement digital twins with their computational capabilities and in-built models for thermodynamics, aerodynamics etc. and provide additional decision-making information to the digital twin.

Key Considerations

There are several factors to consider while ideating and designing a digital twin for optimum performance. The solution should not only address the business problem but do it with maximum efficacy. The essence of a successful digital twin is to capture the right context in which the underlying physical asset is functioning. For example, a solenoid valve used in application A will operate and behave as per the ambient configuration while another valve with a different specification is used for application B and is expected to operate under a different configuration. A well-designed DT system should be able to differentiate between the two instead of treating those in a generic manner.

Secondly, accurate sensing is a must for a digital twin to be effective. Right type and specification of sensors need to be identified for data capture and their calibration should be done on a regular basis to ensure best data quality.

Designing a Digital Twin

A bottom-up approach should be taken to know the physical object in the minutest detail possible, including its static properties. But before that there should be a clarity on the functional specifications and its decomposition and what the system intends to do. It can be purposed to optimize the operation, monitor for potential anomaly or make predictions on the future state or a combination of these functionalities. The next step is to identify the parameters that need to be captured to implement the aforesaid functionalities.

Once the parameters are identified, the focus shifts to how these values will be captured from the physical system. Shortlisting or sensors, communication protocols, processing need of captured data at the edge device. data connection between the physical and digital object and the complete flow should be designed. For example, if the primary job of the digital twin is to optimize operation, then it should be able to capture the relevant data needed for cost analysis, efficiency monitoring etc. along with the data techniques that would be deployed to do so. Say, if operational efficiency of a turbine needs to be monitored then the its emission levels need to be monitored or how well it is combusting fuel to generate the required output.

The physical object is monitored by sensors and data is collected, processed and stored in real time. Using this data, the digital twin can assess operational condition and predict maintenance requirements by using Machine Learning models. As the data is gathered over time, it can be analysed to detect patterns that can help to identify product design problems and suggest improvement.

An important part of a digital twin is to design and develop virtual models that capture information from various aspects of the physical object. Structural model captures the dimensional aspect of the object along with geometries and permissible tolerance levels while behaviour models are based on laws of Physics and capture how the physical object reacts and responds to the environment. Data models maintain all the variables that reflect reality at a given level of abstraction. These models need to be fine tuned and validated individually before they are unified under a digital twin. The whole system then needs to work seamlessly and interact with each other as desired. The complexity of developing it is a huge task and demands a well-knit group of people with the right skill sets who can work as a team to design, develop, validate and optimize the digital twin solution. These are the biggest challenges to design and deploy a digital twin successfully.

Conclusion

Digital twin approach opens new possibilities to provide autonomy for manufacturing assets and interacting processes. Self-aware digital models can monitor, analyse, predict and even prescribe optimal steps to operate critical manufacturing assets and processes. However, a methodical approach is needed to define and develop a digital twin to reap the maximum benefit from the significant investment to be made in technology and human resources. In order to test the waters, it is advisable to start with a smaller but important component in your manufacturing ecosystem. That way it would be easier to secure a buy-in from the senior leadership and the Return on Investment (RoI) can be maximized and showcased to gain confidence for more complex and resource intensive projects.

About the Author :

Mr. Vishal Kelkar

Senior Product Strategist – FIS

Vishal Kelkar is a certified digital manufacturing and smart factories specialist from Indian Institute of Science (IISc), Bengaluru, India. He has 22+ years of business consulting experience and has extensively worked in the areas of product strategy and management, business solutions consulting and industry thought leadership. He has authored business articles, whitepapers and point of views published across industry magazines and blogs.

Mr. Vishal Kelkar is Bestowed with the following Licenses & Certifications :

https://www.linkedin.com/in/vi

Mr. Vishal Kelkar can be contacted at :