Manufacturing Industry – Unlocking Digital Growth with AI

Artificial Intelligence (AI) has the potential to revolutionize the way manufacturing industries plan, develop, and operate.

By using AI technologies such as machine learning, natural language processing, and computer vision, manufacturing companies can achieve valuable advantages: for example, gain detailed insights into their operations, optimize their processes, improve the quality of their existing products, and even open up new markets.

The above insights into artificial intelligence are not new. That raises the question, all the more, as to why more and more organizations aren’t tapping into this potential and using it for themselves.

According to the World Economic Forum, which McKinsey cites as a source, half of all companies are already using AI. For comparison: In 2017 it was every fifth company. Although the development points in the right direction, it can still be interpreted as rather cautious.

So what is stopping industrial manufacturing companies from investing in and implementing artificial intelligence? Let me share some of my experiences in the following paragraphs.

The challenges of implementing AI in the manufacturing industry

The integration of artificial intelligence into manufacturing has become a hot topic in recent years. While there are many benefits to using AI in manufacturing, there are also some challenges that need to be addressed for a successful implementation. These include, among other things:

Infrastructure: To implement AI in manufacturing, the right infrastructure is an essential requirement. That includes the hardware and software required to run AI algorithms, as well as the necessary data storage and processing capabilities. Qualified employees who can develop and implement AI solutions are also important.

Data: Another challenge is the need for large amounts of data. AI algorithms need large amounts of data to learn and make accurate predictions. Collecting and processing this data can be a key challenge, especially for companies that have not invested in its data management.

Cost: Implementing AI in manufacturing is an investment, and companies would do well to carefully weigh the costs against the potential benefits. However, many companies are finding that the benefits of AI, such as increased efficiency and productivity, far outweigh the costs.

Cybersecurity: With AI comes the potential for cyberattacks that can lead to production downtime, data loss, and even physical harm to employees. In addition, AI systems can be more vulnerable to hacking and tampering, which could lead to the theft of sensitive information or intellectual property.

While there are certainly challenges to implementing artificial intelligence in manufacturing, the majority of companies overall agree that the benefits are well worth the effort and investment required.

By addressing the challenges and working to integrate AI into their manufacturing processes, companies can achieve significant competitive advantages.

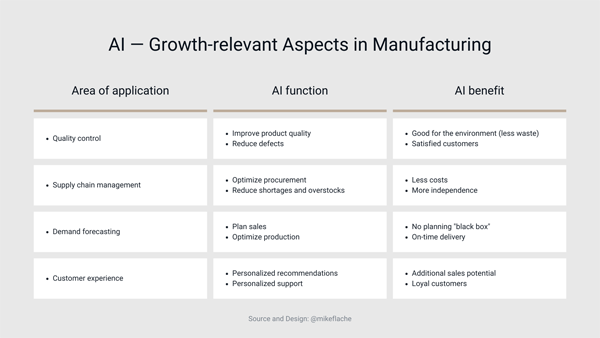

Which growth-relevant aspects AI offers in manufacturing

Artificial intelligence not only enables companies in the manufacturing industry to improve their manufacturing processes or reduce costs. There are a few other ways AI can be used in manufacturing to drive growth.

One of the biggest benefits of AI in manufacturing is its ability to spot potential problems before they arise. By analyzing data from sensors and other sources, AI alerts workers to fluctuations before they become bigger problems. That can save time and money by avoiding costly breakdowns and repairs.

That also allows companies to optimize their production planning. As a result, this leads to significantly shorter throughput times and greater adherence to deadlines and deliveries.

Other advantages that AI offers in production are:

Quality control: AI analyzes large amounts of data to identify patterns that human reviewers may miss. That allows companies to improve the quality of their products and reduce errors. Both can lead to significantly less waste and higher customer satisfaction.

Supply chain management: By analyzing data from suppliers, manufacturers, and retailers, AI can help optimize stock levels and reduce the risk of stock-outs or overstocks. That leads to more efficient processes, lower costs, and more independence.

Demand forecasting: This aspect is crucial for manufacturers to plan production and allocate resources. By analyzing historical data and other factors, AI helps predict future demand and adjust production accordingly.

Customer experience: Finally, AI can improve the customer experience by providing personalized recommendations and support. By analyzing customer data, AI can identify relevant patterns and preferences to make helpful recommendations. That offers companies the opportunity to realize additional sales potential and strengthen customer loyalty.

Artificial intelligence also offers many other advantages for companies in the manufacturing industry, e.g. in product development and design, sustainability as well as in marketing, sales, and service.

Conclusion

Overall, AI is a powerful technology for the manufacturing industry. That will not only help increase efficiency, reduce costs, and improve product quality but also boost growth.

As more and more manufacturing companies adopt AI technologies, we can expect further advances and innovations in the industry.

About the Author

Founder and Board Member Flache International & Flache.org. Advisor and Mentor, Former Entrepreneur and Angel Investor, Most Influential Digital Transformation Specialist (Global Excellence Awards)

Mike Flache is an advisor and mentor, former entrepreneur and angel investor. Together with talented teams, he builds digital businesses worldwide. Onalytica’s analysts named him one of the top-10 global thought leaders in digital transformation. Mike helps high-tech innovators in Silicon Valley, Europe, and Asia grow and scale. Together with the Fundment team, he is currently building one of the next billion-dollar companies in financial technology. Mike is also a partner of Fortune 500 companies and technology vendors. He has worked with executives from companies such as the Silicon Valley Innovation Center, Google, Amazon, Huawei, and Mercedes-Benz.

Mr. Mike Flache is Bestowed with the following Honors & Awards :

https://www.linkedin.com/in/mi

Mr. Mike Flache can be contacted at :

LinkedIn | Email | Personal Website | Twitter | Instagram | Official Website

Also read Mr. Mike Flache‘s earlier article: