When is ZLD Systems Worth the Investment?

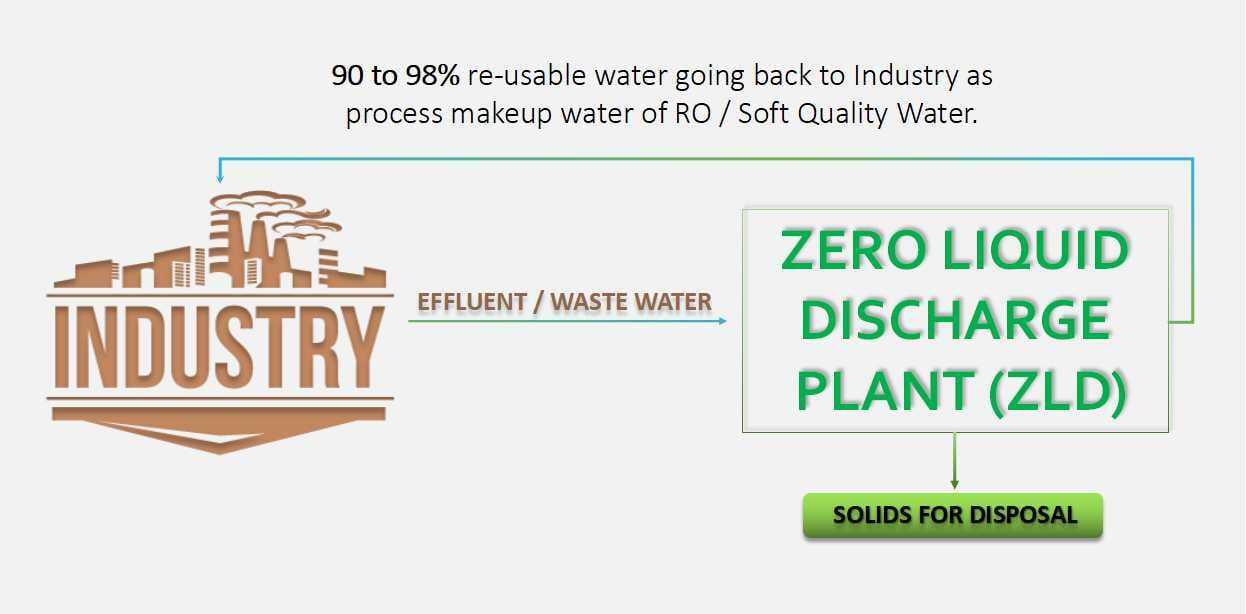

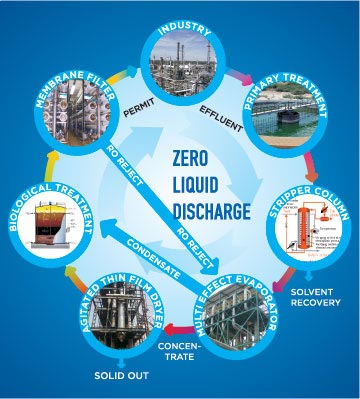

Zero Liquid Discharge (ZLD) is a waste water treatment option that recovers all the water and turns the contaminants into solid waste. This approach eliminates discharge into sewers or waterways. Although zero liquid discharge systems are more complex and expensive than other options, many consider them worthwhile due to their benefits.

Water Becomes Suitable for Reuse

As more stakeholders become increasingly concerned with sustainable practices, they look for new and different ways to prioritize waste reduction and reusability. Zero liquid discharge systems meet both those goals and others.

Meadow Lake Mechanical Pulp operates the only ZLD pulp facility in Canada. Decision-makers sought to improve the company’s waste management practices. Before switching to a ZLD system, it was discharging 6,500 cubic meters of wastewater daily.

The plant also had quality issues characterized by persistent odors, a green color and above-average chemical oxygen demand (COD) levels. Besides making wastewater reuse trickier, these problems negatively affected pulp quality.

Leaders selected a ZLD system and planned a six-month trial to examine its performance. They wanted COD levels to decrease 30% from the baseline levels of 843 parts per million and remain there continuously for six weeks after acclimatization.

Although that was the primary quantitative metric to track, some additional subjective goals were directly linked to high-quality outcomes. Those involved in the trial hoped to see a reduction in problematic, detectible odors and the undesirable green color.

People then took weekly samples. The results surpassed the quantitative goal, showing a 31% reduction in the six-month-average COD level. The outcomes improved even more during the trial’s final six weeks, dropping to an average 53% COD reduction. Plus, the odors substantially decreased, the water’s green color disappeared and the liquid became clearer.

These outcomes supported the plant’s recycling goals, turning the company into a conservation pioneer. Other options are also making wastewater more sustainable, such as turning it into fertilizer rather than having it end up in waterways. Progress in these areas is critical for focusing on a greener future.

Zero Liquid Discharge Systems Make Costs Manageable

The costs for waste water treatment systems can vary significantly based on the methods required, the amount of water to process and a facility’s size. Improper upkeep can also raise a company’s expenses. Just 1/32-inch of scale buildup on a fire tube boiler can cause a 2% fuel efficiency drop, resulting in $72,000 more annual operating costs.

Although zero liquid discharge systems are not usually immediately less expensive than their counterparts, some real-world cases illustrate how they pay for themselves over time, resulting in lower costs overall.

In one case from Kanpur, India, a zero liquid discharge project treated 20,000 liters of textile effluent daily. Before transitioning to that method, it cost the facility the equivalent of up to $5.43 per 1,000 liters of liquid treated. However, ZLD brought the costs down to $2.11 per 1,000 liters. Decision-makers anticipate that adding solar panels to their ZLD setup will further reduce costs by another 40%. Meeting that target would get the facility closer to meeting net-zero emissions targets.

Those involved with this project believe the ZLD technology could work well beyond the textile industry, leading to better wastewater management for pharmaceutical plants, tanneries and others. Once other decision-makers notice this success, they should feel more confident about deploying similar zero liquid discharge systems.

Experiments also showed this approach worked well for minimizing sludge production to only 0.5 kilograms per cubic meter of this toxic, voluminous material. That achievement should also reduce costs since one of the three main sludge management techniques is destruction through thermal processes. If people don’t have to spend time and money on that, they can operate more cost-efficiently.

Is Zero Liquid Discharge Systems Right for You?

These case studies highlight why many leaders use liquid discharge systems to manage their waste water needs. However, if you’re considering doing the same, evaluate several aspects first. For example, how much do your current wastewater discharge methods cost, including disposal-related expenses?

Does the current approach align with regulatory requirements, and will that likely remain the case for the foreseeable future? In addition to the federal regulations mandating the practices of specific wastewater-producing industries, companies must abide by state or local requirements.

People must also analyze the expected costs and expertise related to running and maintaining a ZLD system. Although many options have automated features, people still need specialized expertise to ensure the technology meets performance requirements and provides trouble-free operations.

Finally, leaders can anticipate better outcomes when they specify what they want to achieve while using zero liquid discharge systems. Recall how the first example included quantitative and subjective metrics. Tracking progress toward the stated ideals makes it easier for people to see what’s working and which parts of the system they must still tweak to get the desired results.

Taking a strategic approach like this increases the chances of people spending money in practical ways to develop the systems most appropriate for their business needs. They’re then most likely to see healthy returns on investment for these projects.

About the Author:

Emily Newton

Editor in Chief

Revolutionized

![]()

Emily Jade Newton is the Editor-in-Chief of Revolutionized a popular science publication that dives into the latest innovations in science, technology and industry.

Emily Newton is an industrial writer who enjoys showcasing innovation in her stories.

Emily Newton specialize in writing in-depth articles and blog posts for the industrial and sci/tech sectors.

Emily Newton enjoys researching the latest trends and optimizing articles to perform better in search engines.

Emily Newton can be Contacted at :

e-mail | LinkedIn | FaceBook | Twitter | YouTube | Pinterest | Website

Also read Emily Newton‘s earlier article :