Smart Manufacturing and the Factory of the Future : A Pragmatic Path to Industry 5.0 and Measurable Impact

Executive Summary

Manufacturing is at an inflection point. Persistent supply chain volatility, increasing product complexity, workforce challenges, and rising sustainability expectations are exposing the limits of fragmented digital initiatives. Incremental automation and isolated digital tools are no longer sufficient. What is required is a more holistic transformation of how products are designed, produced, operated, and sustained.

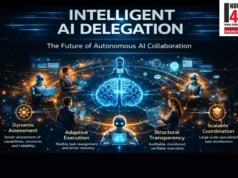

Industry 5.0 reframes the manufacturing agenda around human centricity, resilience, and sustainability. Achieving this vision depends on Smart Manufacturing and the Factory of the Future, enabled by tightly integrated digital technologies, advanced analytics, and adaptive systems that connect engineering, supply chain, manufacturing & operations, quality & regulatory, and service.

This article presents a pragmatic roadmap for manufacturers seeking to move from ambition to execution. It highlights the role of ET-IT-OT-AI integration, Digital Threads & Digital Twins as foundational capabilities, and the practical application of emerging technologies such as Artificial Intelligence including Generative AI and Industrial AI, robotics, and the industrial metaverse.

Industry Context and Key Trends

The transition from Industry 4.0 to Industry 5.0 builds on connectivity and automation but extends the focus to collaboration between humans and intelligent systems, long term sustainability, and operational resilience.

• Integration of ET (Engineering Technologies), IT (Information Technologies), and OT (Operational Technologies): Engineering systems, enterprise platforms, and shop floor operations must converge to enable real time visibility and coordinated execution. This integration forms the backbone of Smart Manufacturing, ensuring that decisions made in design and planning are continuously informed by production and operational reality.

• Digital Continuity Across the Value Chain: Digital Thread connects as-designed, as-built, and as-operated data into a continuous lifecycle view. When implemented through Digital Product Lifecycle Management (PLM) and Connected Manufacturing Operations Management (MOM), it enables traceability, faster feedback loops, improved quality, and more effective compliance management. Digital continuity also shortens the distance between innovation and execution.

• Artificial Intelligence in Manufacturing: Artificial Intelligence is moving from experimentation to scaled adoption. Predictive analytics improve asset reliability and quality performance. Generative AI accelerates design exploration, documentation, and contextual knowledge access. Industrial AI applies these capabilities to complex production environments, enabling adaptive control, anomaly detection, and increasingly autonomous decision making. When combined with robotics, AI enables flexible production, precision operations, and safer, more ergonomic workflows.

• Digital Twins and the Industrial Metaverse: Digital twins provide virtual representations of products, processes, and assets that can be simulated and optimized before changes are made in the physical world. The industrial metaverse extends this capability through immersive environments that support collaborative planning, virtual commissioning, remote assistance, and workforce training.

• Sustainability as a Core Manufacturing Imperative: Sustainability is no longer a parallel initiative. Energy optimization, emissions transparency, and circular economy principles are shaping investment and operational priorities. Digital technologies enable real time ESG monitoring and predictive insights that allow sustainability goals to be embedded directly into manufacturing decisions.

Smart Manufacturing and the Factory of the Future

Smart Manufacturing and the Factory of the Future

Smart Manufacturing and the Factory of the Future are not abstract concepts. Together, they represent an integrated, intelligent, and adaptive manufacturing ecosystem that seamlessly connects physical operations with digital intelligence.

Smart Manufacturing and the Factory of the Future

Smart Manufacturing and the Factory of the Future are not abstract concepts. Together, they represent an integrated, intelligent, and adaptive manufacturing ecosystem that seamlessly connects physical operations with digital intelligence.

Core Principles and Characteristics

• Connected operations ensure that machines, sensors, and enterprise systems share data across the value chain, enabling end to end proactive visibility.

• Closed loop feedback mechanisms use continuous monitoring and analytics to drive automated adjustments that protect quality and efficiency.

• AI driven optimization applies Industrial AI to predictive maintenance, dynamic scheduling, and process optimization, while Generative AI enhances design agility and documentation quality.

• Robotics integration introduces collaborative robots and autonomous systems that increase flexibility, throughput, and workplace safety.

• Digital twins and simulation enable proactive decision making, scenario planning, and faster commissioning of new products and facilities.

• Immersive collaboration through industrial metaverse platforms supports virtual commissioning, ergonomic design validation, and remote expert assistance.

• Sustainable operations rely on real time tracking of emissions, energy, and resource consumption to ensure compliance and continuous improvement.

• Human centric design uses augmented reality, AI guided workflows, and assistive technologies to empower workers, improve productivity, and reduce cognitive and physical strain.

A Pragmatic Roadmap to Transformation

Transformation must be phased, outcome driven, and scalable. Successful manufacturers approach Smart Manufacturing as a journey rather than a single program.

• Assess current maturity by benchmarking capabilities against an Industry 5.0 maturity model and identifying gaps in connectivity, orchestration, and optimization.

• Build strong digital foundations by implementing Digital PLM and Digital Thread to unify product and process data across the lifecycle. Integrate manufacturing execution systems and IoT platforms to establish real time shop floor visibility.

• Enable ET-IT-OT convergence through standards-based architectures and interoperable platforms that connect engineering, enterprise, and operational systems.

• Activate Artificial Intelligence and Generative AI by deploying predictive maintenance, quality analytics, and dynamic scheduling use cases. Apply Generative AI for knowledge assistance and automated documentation and extend Industrial AI into adaptive control and optimization.

• Leverage robotics and automation by introducing collaborative robots for assembly, inspection, and material handling, and combining them with AI to support autonomous and precision driven operations.

• Adopt industrial metaverse capabilities by piloting immersive simulations for factory layout, robotic cell design, and workforce training, then extending to virtual commissioning and remote operations support.

• Embed sustainability directly into operations by integrating ESG metrics into operational dashboards and applying AI driven analytics to optimize energy and material usage.

• Empower the workforce through augmented reality guided workflows, collaborative robotics, and continuous upskilling delivered through immersive and experiential training environments.

Illustrative Examples

• A global manufacturer integrated manufacturing execution and IoT platforms, reducing downtime by 25% and improving overall equipment effectiveness by 15%

• A chemical producer used digital twins to simulate production scenarios, resulting in a 12% reduction in energy consumption

• A medical device company deployed augmented reality guided workflows and collaborative robots, reducing errors by 30% and significantly accelerating changeovers

• An automotive manufacturer applied Industrial AI models to predict equipment failures, cutting unplanned downtime by 40%

• A food and beverage company used virtual reality simulations for operator training, improving onboarding speed by 50%

Outcomes and Value Realization

Organizations that embrace Smart Manufacturing and the Factory of the Future capabilities consistently report measurable business outcomes. These include cycle time reductions of up to 45%, defect reductions approaching 40%, operational cost savings between 15% and 30%, meaningful reductions in energy use and emissions, and improved workforce safety alongside faster skill development.

Conclusion

Smart Manufacturing and the Factory of the Future are no longer optional initiatives for manufacturers across discrete and process industries. They are strategic imperatives. By integrating engineering, information, and operational technologies, applying Industrial AI, robotics, and immersive technologies, and embedding sustainability and human centric design, organizations can achieve the agility, resilience, and competitiveness required in an Industry 5.0 world.

The path forward is pragmatic. Establish strong digital foundations. Scale intelligence and immersive capabilities where they deliver value. Sustain progress through continuous innovation and learning. Industry 5.0 is not about replacing people with machines. It is about building collaborative ecosystems in which technology amplifies human capability and judgment.

To explore practical research, frameworks, and real-world approaches for advancing Smart Manufacturing and the Factory of the Future, visit HitachiDS.com.

About the Author

Mr. Sankar Natarajan

Senior Director & Global Head of Digital PLM, Smart Manufacturing & Ops and Industrial Metaverse Practices

Hitachi Digital Services

Mr. Sankar Natarajan is the Senior Director and Global Head of Digital PLM, Smart Manufacturing & Ops, and Industrial Metaverse practices at Hitachi Digital Services.

Mr. Sankar Natarajan leads the global strategy, solutions, go-to-market initiatives, and delivery of integrated digital transformations across products, factories, operations, and sustainability.

Under Mr. Sankar Natarajan leadership, teams drive large-scale innovation across the Hitachi Group of Companies and a rapidly expanding global client base.

With 20+ years of experience, Mr. Sankar Natarajan is a recognized industry thought leader in engineering, product development, supply chain, manufacturing, and operations.

Mr. Sankar Natarajan partners with leading organizations to develop outcome-driven digital transformation strategies, ensuring excellence in product innovation, supply chain and manufacturing operations, quality, regulatory compliance, and environmental sustainability.

By leveraging design thinking, digital & AI capabilities, and cutting-edge technologies, Mr. Sankar Natarajan helps businesses achieve measurable impact and long-term success.

Mr. Sankar Natarajan can be contacted at:

About Hitachi Digital Services

Hitachi Digital Services, a wholly owned subsidiary of Hitachi, Ltd., is a global systems integrator powering mission-critical platforms with people and technology.

Hitachi Digital Services, a wholly owned subsidiary of Hitachi, Ltd., is a global systems integrator powering mission-critical platforms with people and technology.

Hitachi Digital Services help enterprises build, integrate, and run physical and digital systems with tailored solutions in cloud, data, IoT, and ERP modernization, underpinned by advanced AI.

By combining Information Technology and Operational Technology (ITxOT), Hitachi Digital Services drive efficiency, innovation, and growth across industries.

With over 110 years of Hitachi Group’s engineering and technology leadership, Hitachi Digital Services is powering smarter platforms for a safer, more sustainable future.

To learn more, visit hitachids.com