Comprehensive Predictive Monitoring for the Process Industry

Precognize is an innovative process manufacturing technology company that is part of the prestigious process automation corporation The SAMSON Group. Precognize focuses on helping process manufacturing companies to run more efficiently and maximize productivity by resolving bottlenecks in operations, reducing unexpected downtime, and improving maintenance scheduling.

Our flagship product is SAM GUARD®, a comprehensive predictive monitoring solution for process manufacturing plants. SAM GUARD provides advanced insights into operating conditions and early warning of potential equipment failures. The solution uses artificial intelligence (AI) and machine learning (ML) to learn what “normal” processes look like and recognize anomalies quickly and accurately.

SAM GUARD filters out false alarms to prevent engineers from becoming overwhelmed and avoid alarm fatigue, without requiring any specialist equipment. SAM GUARD continuously monitors customer data across the entire plant without requiring any specialist equipment. The system picks up on the earliest signs of equipment failure or inefficiencies to reveal problems while they are still relatively minor and easy to fix. To prevent engineers from becoming overwhelmed and avoid alarm fatigue, SAM GUARD automatically filters out false alarms. SAM GUARD’s solution provides all stakeholders with a comprehensive visualization of the plant and its process in the form of a digital twin, helping speed up root cause analysis and enabling virtual resolution for plant issues.

SAM GUARD filters out false alarms to prevent engineers from becoming overwhelmed and avoid alarm fatigue, without requiring any specialist equipment. SAM GUARD continuously monitors customer data across the entire plant without requiring any specialist equipment. The system picks up on the earliest signs of equipment failure or inefficiencies to reveal problems while they are still relatively minor and easy to fix. To prevent engineers from becoming overwhelmed and avoid alarm fatigue, SAM GUARD automatically filters out false alarms. SAM GUARD’s solution provides all stakeholders with a comprehensive visualization of the plant and its process in the form of a digital twin, helping speed up root cause analysis and enabling virtual resolution for plant issues.

Setup Process:

SAM GUARD’s solution begins with setting up a sophisticated interconnected representation of the factory and creating a set of models that typify normal operation. The total time for the setup phase is just two weeks, and no special hardware is required. The models are then used in online operation to detect anomalies that indicate problems in the factory and can provide the starting point to analyzing the root cause of those problems.

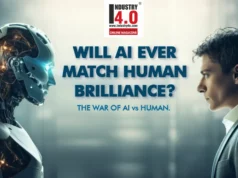

The first step in the setup process relies on our patented method for creating an interconnected asset representation of the factory, which combines two data sources:

– A digital twin of the factory and processes

– Historical data from sensors in the factory

The diagram above shows the workflow needed to set up the interconnected representation of the plant. P&ID diagrams are combined with the customer’s process engineering knowledge of causal factory processes to produce an enriched digital twin of the factory. Historical sensor data from the customer data historian is then added to the twin to produce the interconnected representation. Because the interconnected representation includes every item of equipment and every process in the factory along with their past behavior, it includes all the information needed to enable predictive process monitoring for the whole factory.

In the second step of the setup process, the patented SAM GUARD aggregation method uses this interconnected representation to cluster all sensors that participate in processes related to each item of equipment (e.g., a valve, heat exchanger, or pump). This causal information in the interconnected representation ensures that anomalous behavior in an equipment cluster is likely to have a root cause in that cluster. As a result, the equipment clusters can be monitored independently without damaging model accuracy. Because every process in the interconnected representation affects at least one item of equipment, and every item of equipment in the interconnected representation has a corresponding cluster, the entire interconnected representation (and thus, the factory itself) can be completely monitored using the clusters.

The final step in the setup process is the initialization of two algorithms for each equipment cluster:

– AI anomaly detection model – Characterizes normal behavior for the cluster using the historical data from the interconnected representation.

– A set of calculated indicators – Mathematical functions of sensor data that track the behavior of processes in the cluster relative to a desired target behavior.

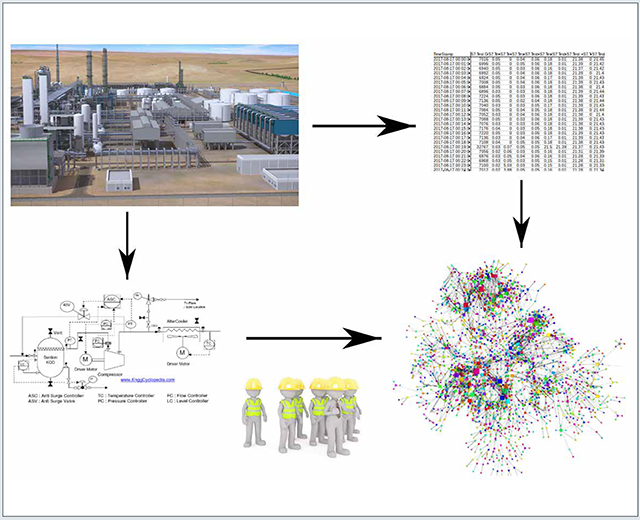

The first step of online operation is the detection of anomalous behavior. Incoming sensor data from each equipment cluster is continuously scored by the cluster’s AI model to indicate the degree to which it is anomalous. However, most anomalies are not interesting to the customer. Real problems in the factory are likely to correspond to significant and gradually worsening anomalies, as shown in the figure on page 5. Anomalies that meet these conditions, called events, trigger alerts that are presented to process engineers for analysis.

The second stage of online operation is the hint system, which uses the calculated indicators to assist process engineers in finding the root cause of events. The hint-assisted root cause analysis can be carried out either by the customer or by the experienced SAMSON Analytical Monitoring Services (AMS) team. When an event is triggered for a specific piece of equipment, all the corresponding calculated indicators are evaluated near the trigger time, resulting in a set of hints. The hints are prioritized according to their likelihood of pinpointing the cause of the event, using a classifier trained on feedback from previous hints. These smart hints help process engineers to find the root cause of the problem and make recommendations for corrective actions and follow up checks. This root cause analysis could also support future plant optimization by identifying loopholes in process relations that have been neglected in traditional mass and energy balance calculations.

Summary:

In this way, SAM GUARD provides a complete solution for predictive process monitoring. It monitors the entire plant, producing accurate, early alerts about anomalies while ignoring irrelevant changes to plant operations. Additionally, SAM GUARD’s hint system provides actionable recommendations for fixing localized problems which speeds up issue resolution and minimizes suspension of operation.

For example, SAM GUARD prevented shutdown at a mining plant by alerting engineers to a broken sensor which would have caused a clogged furnace. In another example, SAM GUARD was able to prevent $1.1 million in damage at a petrochemical plant by preventing the failure of the compressor that controls the air pressure of the valves of the entire plant. In yet another example, several main production units of a chemical plant were modelled using SAM GUARD over the course of a few days. It indicated problems at the thermal incinerator, oxygen flow meter, and blower. After resolving these issues, unplanned shutdowns were measurably reduced from 14% to 10%, leading to a substantial increase in the overall plant operational availability.

With the help of SAM GUARD, process manufacturing companies are able to maximize productivity, minimize downtime, and ensure that all processes and equipment run as efficiently as possible, without causing extra stress to engineers.

About Ms. Elena Klebanov

Ms. Elena Klebanov,

Managing Director,

Precognize Innovations (acquired by Samson)

Ms. Elena Klebanov is an experienced CEO with over 5 years of leadership background.

Ms. Elena Klebanov utilizes big data and analytical insights to formulate strategic plans, she nurtures Business Intelligence for ongoing enhancement of company performance.

Ms. Elena Klebanov is a Versatile innovator with proficiency in strategic planning and growth hacking, she Guides diverse, cross-cultural teams to successfully attain organizational objectives.

Ms. Elena Klebanov exhibits outstanding capabilities in brand management and negotiation.

Ms. Elena Klebanov enthusiasm lies in applying state-of-the-art technologies and methodologies to address real-world challenges, creating substantial value for our customers.

Furthermore, Ms. Elena Klebanov is dedicated to fostering a collaborative, inclusive, and innovative culture within her team and organization.

Ms. Elena Klebanov is Bestowed with the following Awards:

https://www.linkedin.com/in/le

Ms. Elena Klebanov can be contacted at:

About SAMSON Precognize Innovations :

Precognize is a predictive analytics software company in Haifa, Israel, addressing the process industry. It is part of SAMSON Group, headquartered in Frankfurt, Germany, specializing in control valve engineering.

Precognize combines sophisticated technologies of AI and HI (SME’s knowledge) to achieve maximum asset’s availability and performance. Precognize has been nominated as Technology Pioneer 2018 by World Economic Forum, as the Enabling Technology Leadership Award for Predictive Maintenance for Heavy Industries, Europe, by Frost & Sullivan.

Precognize’s patented and unique technology with SAMSON’s hundred plus years of expertise and global presence are set to expedite the digital transformation journey of the process industry.

Predict, Recognize and Act!

In-short, Precognize!

SAM GUARD: Empower your success in process industry through predictive maintenance.

SAM GUARD: Empower your success in process industry through predictive maintenance.

SAM GUARD®, a cutting-edge predictive analytics software tailored for the process industry, a predictive analytics software for the process industry, quickly and accurately identifies equipment failures and suspicious operating modes days to weeks in advance.

By harnessing the combined capabilities of Artificial Intelligence (AI) and Human Enhanced Machine Learning (HI), SAM GUARD® empowers you to elevate your plant’s operational availability, performance, and production output.

With SAM GUARD®, you gain the ability to:

1. Preemptively detect equipment failures.

2. Pinpoint questionable process behavior.

3. Identify suspicious operational modes.

4. Delve into the underlying causes of anomalies.

SAM GUARD® equips you with a comprehensive suite of tools to enhance the reliability and efficiency of your industrial processes.

To lean more about SAM GUARD :