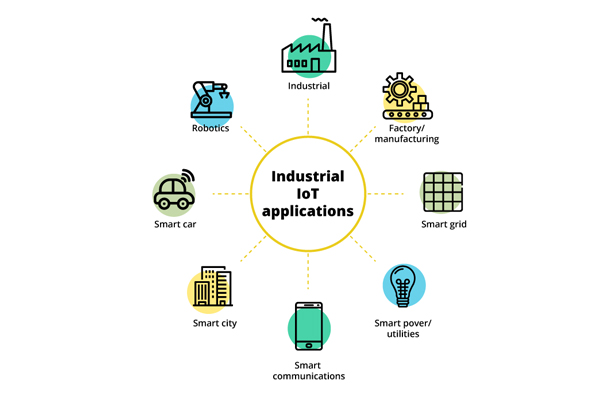

Industrial Internet of Things – IIoT

Over a period of many years manufacturing companies tried to standardize their OT levels with a particular brand from Automation world. However, in their pursuit of exploring industry 4.0, they will need to contemplate becoming automation platform agnostic to achieve flexibility, agility, and cost competitiveness in the future.

IIoT (Industrial Internet of Things) software being platform independent offers several advantages and is desirable for multiple reasons:

1. Interoperability:

Platform-independent IIoT software facilitates seamless integration with diverse hardware, devices, and systems, irrespective of their underlying platforms or protocols. It encourages interoperability within an industrial ecosystem, enabling data exchange and communication across heterogeneous systems. This flexibility empowers companies to connect and utilize a broad array of devices and technologies, regardless of the vendors or platforms involved.

2. Scalability and Flexibility:

Platform-independent IIoT software allows for easy scalability and adaptability. It can accommodate the addition or removal of devices, sensors, or systems without requiring extensive modifications or reconfigurations. This flexibility is crucial in dynamic industrial environments where the technology landscape is constantly evolving. It enables companies to scale their IIoT deployments, integrate new technologies, and adjust their systems as needed without being limited by platform-specific constraints.

3. Vendor Neutrality:

Platform-independent IIoT software avoids vendor lock-in and promotes vendor neutrality. It allows organizations to choose hardware, devices, and systems from different manufacturers or suppliers based on their specific needs and preferences. This independence empowers companies to select the best-of-breed solutions for each aspect of their IIoT infrastructure, avoiding the risk of being tied to a single vendor and enabling them to leverage competitive pricing, innovation, and support options from multiple sources.

4. Future-Proofing:

By adopting platform-independent IIoT software, companies can future-proof their investments. Industrial systems often have long lifecycles, and technology advancements may require updates or replacements of certain components over time. Platform independence ensures that the IIoT software can continue to function and integrate with new technologies, protocols, or devices that may emerge in the future, reducing the risk of obsolescence and protecting the longevity of the investment.

5. Collaboration and Ecosystem Integration:

Platform-independent IIoT software facilitates collaboration and integration within an industrial ecosystem. It enables companies to seamlessly connect and share data with partners, suppliers, or customers who might be using different platforms or technologies. This openness promotes data sharing, collaboration, and the creation of value-added services or applications that span across multiple organizations or industries.

In summary, platform-independent IIoT software enhances interoperability, scalability, flexibility, vendor neutrality, future-proofing, and collaboration within industrial ecosystems. It allows organizations to leverage diverse technologies, integrate with different platforms, and adapt to evolving requirements, ensuring optimal utilization of IIoT capabilities and maximizing the potential benefits of digital transformation in industrial settings.

“While brand loyalty can be beneficial in certain cases, it is important for manufacturing companies to periodically assess their options, explore different automation brands, and make informed decisions based on their specific needs, technological advancements, competitive landscape, and market conditions. This approach ensures that the chosen automation solutions align with their requirements, drive efficiency, and contribute to long-term success”

-Paresh Pansare

CEO, MCPM Software India Pvt.Ltd.

About the Author :

Mr. Paresh Pansare

Mr. Paresh Pansare

Chief Executive Officer,

MCPM Software India Pvt. Ltd.

Mr. Paresh Pansare can be contacted at :

About MCPM Software India Pvt. Ltd.

MCPM stands for “Measurement & Control for Process & Manufacturing” and was formed to provide State of the Art Solutions to a wide range of industrial clients. It represents esteemed organizations like Auvesy MDT, Ocean Data Systems, Atvise, Bachmann, Intelecy, Parsec etc.

With offices in Norway, Thailand, India, and the United Arab Emirates MCPM is engaged in offering state of the Art Solutions by world leading principals to the System Integrators and End users. MCPM is a company primarily focused on delivering solutions in software and building a closely knit Ecosystem of partners and System Integrators.

MCPM can be contacted at: