The rising importance of MES in modern manufacturing

MES is not just a buzzword; it’s a game-changer that revolutionizes operations & drives digital transformation (Industry 4.0)

Would you ever imagine an orchestra ? without a conductor ?. Each musician may be skilled, but the lack of coordination could lead to chaos.

Manufacturing also is like a complex orchestra ?with 100s of musicians (resources) but unless a conductor is there to harmonize every element of the production process, it would be a chaos.

The role of an orchestra conductor can be compared to the function of MES (Manufacturing Execution System) in production.

Synchronization & Coordination: Just like an orchestra conductor synchronizes the musicians & instruments, MES coordinates the various elements of production. It ensures that all processes, equipment, & people work in harmony to achieve optimal performance & efficiency.

Communication and Direction: An orchestra conductor communicates the vision & direction of the musical performance to the musicians. Similarly, MES provides real-time instructions, guidelines, & work orders to operators & machines, ensuring everyone is aligned & working towards the common production goals.

Workflow Management: The conductor manages the flow of the musical composition, controlling the tempo, dynamics, & transitions. Likewise, MES orchestrates the workflow in production, ensuring the smooth flow of materials, tasks, & information across different stages of the manufacturing process.

Collaboration & Collaboration: The conductor fosters collaboration among musicians, bringing out the best in each individual & creating a cohesive sound. Similarly, MES encourages collaboration between departments, such as production, quality, & maintenance, facilitating seamless cooperation & maximizing overall operational performance.

Performance Monitoring & Adjustments: The conductor constantly monitors the orchestra’s performance, making adjustments & providing feedback to achieve the desired outcome. Similarly, MES monitors production processes in real-time, collects data, & provides insights to optimize performance, identify bottlenecks, & make timely adjustments for continuous improvement.

Overall Control & Optimization: The conductor has overall control of the musical performance, balancing different sections, & ensuring a high-quality outcome. In the same way, MES provides control & optimization capabilities in production, enforcing SOP, optimizing resource allocation, & facilitating data-driven decision-making for improved productivity & quality.

By drawing these parallels, we can understand how MES acts as the conductor of manufacturing operations, harmonizing processes, resources, & data to create a symphony of efficiency, quality & success.

MES is beyond just the Visibility & Analytics tool

MES Core Capabilities

- Prod O. Management – Download from ERP, break into job order / workorder, Generate Sr. No, Print labels, track across shop, release/hold/cancel orders

- Scheduling – Schedule / re-schedule across shops as master-child

- Monitor – OEE, Downtimes, Alerts /warnings management (Andon) etc.

- Production Control – Start or Stop lines / machines, Pokayoke

MES Additional Capabilities

- Recipe / Setup management – Auto recipe, SP – Defn. / Specs. / Deviations

- Quality management – Inspection, Error proof & pokayoke, SPC / SPA, Compliance, Track & trace, Quality Containment

- DWI

- BOM – Inventory mgmt. – Material Pull, WIP tracking, FIFO, Kitting

? Debunking Misconceptions: One common misconception is that MES is merely a visibility and analytics tool. While it does provide real-time insights and analytics, MES goes beyond that. It integrates systems, automates manual processes, enforces standard operating procedures, and enables end-to-end traceability. It’s a comprehensive solution that empowers manufacturers to optimize operations and achieve operational excellence.

? So, if you think MES is just a passive observer, think again! It actively drives process improvement, enhances quality control, reduces costs, and facilitates compliance with regulatory standards. It empowers manufacturers to make data-driven decisions, proactively address bottlenecks, and continuously improve their operations.

“Empowering Manufacturing Excellence: Unleash the Power of MES!” : MES is a key to Industry 4.0

Enterprises now realize that MES is critical for digitalization and Industry 4.0. There are changes in MES across technology, business outcomes, business models driven by both industry maturity and external events. Enterprise need to develop MES strategy which delivers business outcomes and also put the enterprise on the roadmap to Industry 4.0.

? Embrace the MES Revolution: As the manufacturing landscape continues to evolve, MES adoption is no longer a luxury but a necessity. It’s time to leverage the power of MES and stay competitive in the digital era. Let’s embrace this transformative technology and unlock new opportunities for growth and success.

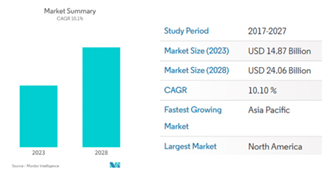

MES Market Analysis

Global Manufacturing Execution Systems (MES) Strategic (globenewswire.com)

https://www.mordorintelligence.com/industry-reports/manufacturing-execution-systems-market

According to The MES Market size is expected to grow from USD 14.87 billion in 2023 to USD 24.06 billion by 2028, at a CAGR of 10.10% during the forecast period (2023-2028).

Mordor Intelligence Research & Advisory. Mordor Intelligence. Retrieved July 7, 2023, from https://www.mordorintelligence.com/industry-reports/manufacturing-execution-systems-market

Feel free to reach out if you want to learn more about MES or discuss how it can revolutionize your manufacturing operations. Let’s create a symphony of success together! ?

#MES #Manufacturing #DigitalTransformation #Orchestration #OperationalExcellence #DataDrivenDecisions #Infographic

How do you conduct an orchestra?

The role of MES is to synchronize various resources (equipment and people) and processes to create a masterpiece of efficiency, quality, and agility. From planning to execution, MES orchestrates tasks, resources, and data flow seamlessly creating the symphony!

MES ensures smooth collaboration between different departments, optimizing production schedules, managing inventory, and synchronizing workflows for maximum efficiency.

About the Author:

Mr. Hemant Patil

Head of IoT – Kagool, UK.

Mr. Hemant is a Subject Matter Expert for Smart Factory and is an evangelist for Industry 4.0 solutions for the manufacturing industry He carries 30 years of rich experience of design and deployment of Plant floor applications and IT systems using varied technologies. During his professional career, Hemant has served many manufacturing giants and have delivered complex IT programs and projects globally for Auto, Aero, IHM, Steel, Refineries and Process industry. Hemant has a passion of working as a catalyst for the organisations to embrace digital transformation leveraging Industry 4.0 principles and framework, and he loves to mentor teams on this journey. Hemant finds time to write technical articles and travel blogs on leading industrial magazines like Automation World, EFY and the digital platform of LinkedIn.

Mr. Hemant has been associated with premier organizations such as GE and TATA throughout his career and has served reputed logos globally.

Mr. Hemant currently heads the IoT business at Kagool, UK.

Mr. Hemant is a B.E. Computer Engineer from Pune university and has completed his graduation from a pioneer institute, Pune Institute of Computer Technology, in the year 1991.

Mr. Hemant Patil can be contacted at :

Also read Mr. Hemant Patil’s earlier article: