Predictive Drilling Analytics for Stuck Pipe Detection

Background:

The Oil & Gas Industry is facing incredible challenges amidst COVID-19 pandemic. The combined demand implications from the current pandemic and long-term energy demand mix are setting the scene for a demand-supply uncertainty. Consequently, operators are focusing on faster returns compared to long term capital investments on conventional energy resources, which puts a premium on assets and organizations with low breakeven capabilities.

Unprecedented capital and operating spending cuts, as high as 50%, have been announced to secure the economic platform required to advance the transition on a very aggressive timeline. The new (ab)normal environment requires oil and gas organizations to digitally enable themselves to respond with agility and drive business performance with approaches and ideas which are transformative in nature. And one of the most cost intensive operations in the entire Oil and Gas value chain is drilling for both exploration and subsequent extraction of oil. These processes generate humongous amounts of both structured and unstructured data and the inability to analyse them accurately and quickly, hugely increases the uncertainty in these operations and puts and risks millions of dollars.

Hence optimizing the value chain leveraging exponential technologies like Artificial intelligence (AI), Machine Learning, Big Data analytics, Edge, IOT to enable intelligent workflows enveloped by a hybrid cloud framework is imperative. In this publication we will be focussing on predictive drilling Analytics project where we have successfully applied Machine Learning, Artificial Intelligence (AI) and big data.

Hence optimizing the value chain leveraging exponential technologies like Artificial intelligence (AI), Machine Learning, Big Data analytics, Edge, IOT to enable intelligent workflows enveloped by a hybrid cloud framework is imperative. In this publication we will be focussing on predictive drilling Analytics project where we have successfully applied Machine Learning, Artificial Intelligence (AI) and big data.

Introduction:

Predicting drilling operation failure is a complex task. Even though huge volumes of data are generated in the drilling operation, those data are typically of different types, formats, and structures. There have been enormous focus and investments on predicting patterns that could help avoid failures such as stuck pipe, pack off etc. but a true solution remained elusive for a long time.

IBM has developed an Al based predictive drilling analytics solution that successfully helped operators to predict failure and reduce non-productive time (NPT).

The stated solution aims to digitally transform drilling operations and to develop an intelligent support system thorough the deployment of advanced technologies and optimization of work processes in a collaborative work environment to reduce cost, maximize efficiency, value, and improve HSE.

IBM envisions to help clients in process compliance and efficiency in the following areas:

- Prevent NPT related stuck pipe events

- Real time remedial actions to prevent stuck pipe scenario

- Enhance operation performance and work efficiency

- Monitor/tracking of live operations

- Better understanding of operation deviated from normal trend to have better operation solution

- Scaling up to multiple rigs with marginal resource needs.

We share below the methods, procedures, process, and brief description for in following paragraphs:

Methods, Procedures, Process:

Data is at the heart of digital transformation and upstream industry is known to generate huge volumes of data both structured and unstructured. Much of the data thus acquired are not even utilised due to its quality and the inability to process such volumes manually. It is practically impossible to manually crunch this huge volume of data in good time to generate useful business insight.

There is also time delay between when data is generated and when data can be utilised to make some business decision, partly due to latency in the data transmission channel and partly due to number of miles data need to travel back and forth.

To make the matter worse, there is always an issue with data interoperability and reluctance of adherence to industry open standard by data acquirers/providers.

That is where the exponential technologies come to our aid in zipping through pile of structured and unstructured data to discover and disseminate business insight.

These Artificial Intelligence(AI)/Machine Learning (ML) based solutions assist Geoscientist, Drilling engineers and drilling operators to apply engineering principles and workflow in reservoir analysis, well planning methodologies, modelling large, complex data sets to develop efficient way to carry out reservoir characterisation, early warning systems for Drilling Dysfunctional events and to speed up the overall well planning window. All these aid in time and cost saving.

These solutions have some form of models specific to particular use cases and the process of such model development is given below. Model building essentially has five main components:

1. Data Analysis: Analysis of all available data from data Quality perspective,recommendation on pre-requisite data quality and extraction of specific key data values required for the AI model. This process also deals with data clean up strategy and missing value imputation procedures.

2. Data Collection and Data Preparation: Hook up to multiple data source (Offset well data,Real-time Drilling Data source, DDR data source, well design data source) and put into a centralised data repository which can handle super-fast analytics workload with large data set. Data cleaning and restructuring is done as necessary.

3. Data Ingestion: Cleaned and restructured data is then fed into IBM Analytics platform to build a ML/AI based prediction model per use case.

4. Live piloting of model: Run the model on pilot set of data and make necessary adjustment before releasing it for general use.

5. Business Intelligence dashboards: To monitor and disseminate business insight to wider audience.

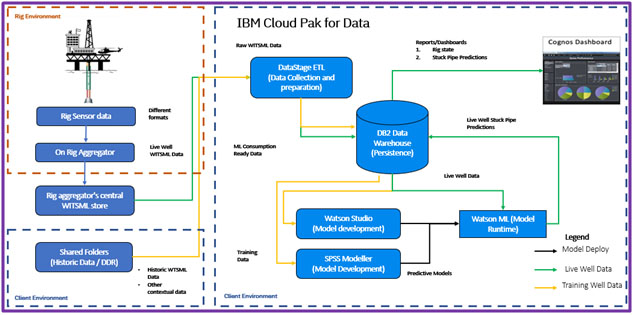

High level Architecture of the Solution:

Results, Observations:

1. Predictive Drilling Analytics

- 70-80% True positive rate of stuck pipe event detection

- 15-30% False positive rate of stuck pipe event detection

- Prediction time window greater than 3 hours

- It is also observed that data quality is generally an issue which can have an adverse impact on the prediction accuracy

To summarize an organisation embarking on this journey should look end to end transformation and enabling the workforce to embrace the change. The management driven by this vision, needs to endeavour to adopt these technologies, equipping relevant stakeholders with new age tools and processes, networking with an extended ecosystem suited for innovation embracing an open, flexible and hybrid cloud framework.

About the Authors :

Mr. Sandeep Debray

Partner & Industry Leader – Chemicals and Petroleum,

IBM India

LinkedIn : sandeepdebray

Twitter : https://twitter.com/sandeepdebray

Mr. Prasanta Saha

IBM O&G SME – Chemicals and Petroleum,

IBM India

LinkedIn : prasanta-saha