Smart, Not Blind : A Human-Centric Vision for India’s Industrial Future

Reflections and learnings from Two Decades of Industrial Transformation

After implementing automation solutions across three continents and founding technology ventures over 20+ years, I’ve learned a hard truth: universal automation solutions don’t exist. What works in labor-scarce Germany fails spectacularly in labor-abundant India.Today, as Indian industry rushes toward Industry 4.0, we risk adopting Western solutions to Western problems—ignoring our unique strengths and social realities.

The Western Automation Trap

Western automation emerged from the demographic crisis—aging populations and shrinking workforces. Germany’s Industry 4.0 addresses a projected 6 million worker shortage by 2030.Japan’s Society 5.0 tackles a society where adult diapers outsell baby diapers.

India’s reality is starkly different:

● 1.4+ billion population with 65% under age 35

● 12 million youth entering job markets annually

● 600+ million working-age population exceeding all of Europe.

When you have abundant labor, adopting labor-replacement technologies creates social catastrophe, not competitive advantage.

The Technology Tsunami: Converging Disruptions

Current automation differs fundamentally from past industrial revolutions. AI, robotics, IoT, and machine learning now converge to eliminate entire job categories within months, not years:

● Generative AI replaces designers, analysts, content creators

● Computer vision automates quality control, inspection roles

● Robotic systems handle assembly, packaging, material handling

● Predictive algorithms eliminate maintenance, logistics positions

The exponential improvement curve means decisions made today have vastly different implications than five years ago. What required PhD expertise now runs on smartphones. Million-dollar systems cost hundreds of thousands today, tens of thousands tomorrow.

The Unemployment Time Bomb: Quantifying the Crisis

Based on my analysis of Indian industrial sectors, automation adoption could displace:

● Immediate Risk (1-3 years):

○ Data entry, basic customer service: 8-10 million jobs

○ Simple assembly, quality control: 5-7 million jobs

○ Transportation coordination: 2-3 million jobs

● Medium-term Risk (3-7 years):

○ Manufacturing roles, middle management: 15-20 million jobs

○ Basic design, engineering functions: 5-8 million jobs

○ Accounting, routine healthcare: 3-5 million jobs

● Conservative displacement estimate:25-35 million direct jobs across five major sectors within a decade. Including dependents and ripple effects: 75-200 million people affected .

● For context, this exceeds the entire population of most countries and dwarfs any historical industrial transition.

Lessons from Global Automation Experiments

My implementation experience across emerging markets provides sobering precedents:

● Brazil (1990s):

○ Manufacturing automation eliminated 2.5 million jobs, triggering:Persistent unemployment above 12%

○ Urban migration overwhelming infrastructure

○ Political instability lasting decades

● South Africa:

○ Automotive automation reduced employment 40% in five years, contributing to29% unemployment and widespread social unrest.

● India’s scale magnifies these risks exponentially.

The Inequality Amplifier: Mathematics of Wealth Concentration

Automation requires massive capital only large corporations can afford:

● Automated factory: ₹500 crores investment, 100 employees

● Traditional factory: ₹50 crores investment, 2,000 employees

This creates a “barbell economy”—wealthy technology owners at one end, massive unemployment at the other, shrinking middle class between. In India’s caste-conscious society,where occupation determines social status, this threatens fundamental social structures.

Geographic concentration compounds the problem:

Geographic concentration compounds the problem:

● Automation benefits flow to tech hubs (Mumbai, Bangalore, Chennai

● Employment losses hit smaller industrial towns nationwide

● Rural areas absorb displaced workers, straining agricultural systems

The Democratic Governance Challenge

Mass unemployment plus extreme inequality overwhelms democratic institutions designed for gradual change. When private automation decisions determine employment for millions,democratic systems appear powerless to protect citizen interests.

Potential outcomes:

● Anti-technology populism reversing economic progress

● Authoritarian responses sacrificing democratic freedoms

● Interstate tensions as automation benefits concentrate regionally

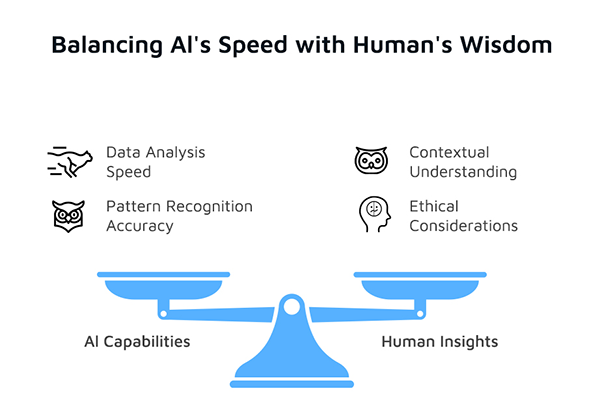

My Strategic Framework: Human-Centric Automation

Twenty years of implementation experience suggests a three-tier approach:

● Tier 1: Safety-Critical Automation (Immediate)

○ Nuclear facilities, chemical processing, hazardous manufacturing

○ Justification: Human safety supersedes employment considerations

○ Examples: Toxic material handling, precision pharmaceutical production

● Tier 2: Collaborative Enhancement (3-7 years)

○ Human-machine partnerships preserving employment while improving productivity

○ Applications: Automotive: Robots handle welding, humans manage assembly

○ Textiles: Automated cutting, human finishing and quality control

○ Healthcare: AI-assisted diagnosis, human patient interaction

○ Outcome: 40-60% productivity gains while maintaining jobs

● Tier 3: Strategic Replacement (7+ years)

○ Full automation only after alternative employment creation and proven transition programs

Prerequisites: Comprehensive retraining, social safety nets, economic alternatives

Sectoral Intelligence: Where to Apply Automation

High-Value Targets:

● Precision manufacturing (aerospace, pharmaceuticals)

● Dangerous operations (mining, chemical processing)

● Quality-critical processes (medical devices, defense equipment)

Human-Centric Enhancement:

● Automotive assembly, textile production, food processing

● Customer service, healthcare delivery, education

● Creative industries, complex problem-solving roles

Protection Zones:

● Labor-intensive services requiring cultural understanding

● Small-scale manufacturing supporting local economies

● Industries where human creativity drives value

The Innovation Paradox: Why Over-Automation Reduces Competitiveness

Excessive automation paradoxically undermines innovation capacity. Human creativity requires active engagement with real problems—precisely what automation eliminates.

India’s traditional strengths at risk:

● Jugaad innovation requiring hands-on problem-solving

● Frugal engineering based on resource constraints understanding

● Adaptive manufacturing responding to local market needs

Over-automated organizations become:

● Dependent on foreign technology vendors

● Less adaptable to changing market requirements

● Disconnected from customer needs and local conditions

Policy Recommendations: Building India’s Automation Framework

Immediate Actions:

Employment Impact Assessment: Mandate studies for automation projects above ₹10crore

Graduated Tax Structure: Higher taxes for job-displacing automation, incentives for job-enhancing technology

Strategic Skills Investment: Focus on human-machine collaboration rather than replacement

Medium-term Initiatives:

Innovation Ecosystem Development: Fund research into “appropriate automation” forIndian conditions

Social Safety Net Expansion: Unemployment insurance, retraining programs,entrepreneurship support

Regional Development Balance: Ensure automation benefits don’t concentrate on existing tech hubs

Long-term Vision:

Technological Sovereignty: Develop indigenous automation capabilities serving Indian social and economic objectives

Export Leadership: Position India as developer of inclusive automation technologies for emerging markets

The Competitive Advantage of Measured Adoption

Contrary to conventional wisdom, India’s human-centric approach could create sustainable competitive advantages:

Flexibility Benefits:

● Human-operated systems adapt faster to changing requirements

● COVID-19 proved automated systems less resilient during disruptions

● Custom manufacturing favors human creativity over rigid automation

Market Differentiation:

● Growing consumer preference for artisanal, personalized products

● Service quality advantages from human interaction

● Innovation capacity from hands-on manufacturing engagement

Cost Realities:

● Full automation requires 300-500% higher capital investmen

● 7-10 year payback periods exceed most Indian manufacturers’ financial capacity

● Maintenance costs and technical dependence create hidden expenses

Three Future Scenarios for India

Scenario 1: Aggressive Automation Adoption

Outcome High productivity, massive unemployment, social unrest, political instability

Risk: Short-term economic gains, enormous long-term social costs

Scenario 2: Technology Resistance

Outcome: Employment preservation, economic stagnation, eventual forced adjustment

Risk: Delayed rather than solved fundamental challenges

Scenario 3: Strategic Human-Centric Integration

Outcome: Balanced productivity growth with social stability

Requirements: Unprecedented policy coordination and social investmen

Benefit: Both economic competitiveness and social cohesion

The Entrepreneurial Opportunity: Leading Inclusive Innovation

My recent ventures focus on “appropriate automation”—technologies achieving 60-80% of full automation benefits at 30-40% of the cost while preserving employment. Early market response suggests significant export potential to other developing economies facing similar challenges.

India’s potential leadership areas:

Collaborative robotics for labor-abundant environments

AI-assisted human decision support systems

Flexible manufacturing technologies balancing efficiency with employment

Human-centric industrial design and implementation

Conclusion: Wisdom Over Speed

Industrial leadership isn’t about adopting technologies fastest—it’s about adopting them most intelligently. India has an unprecedented opportunity to demonstrate that technological progress and social development can be mutually reinforcing rather than competing objectives

The choice is clear:

● Follow others down a path that may not serve our interests

● Pioneer a uniquely Indian approach balancing technology with humanity

● Lead global development of inclusive industrialization models

● After two decades of implementing industrial transformation across diverse economies, I’m convinced the future belongs not to the most automated nations, but to those that most intelligently integrate human creativity with technological capability.

● India has all necessary ingredients—abundant human resources, growing technological capacity,democratic institutions, and entrepreneurial energy. The question isn’t whether we can afford this measured approach, but whether we can afford not to take it

● The stakes extend beyond our borders. Success demonstrates that inclusive industrialization is possible, providing a template for other developing economies. Failure means repeating others’mistakes and facing the social consequences that excessive automation has created elsewhere.

● The demographic dividend others see as temporary could become permanent competitive advantage if leveraged intelligently. The time to choose our path is now.

About the Author :

Mr. Chetan Kulkarni

Founder and Director

Elansol Technologies Private Limited

Mr. Chetan Kulkarni as the Director of Elansol Technologies is passionate about leading a team of experts who are dedicated to providing cutting-edge solutions.

Mr. Chetan Kulkarni with 19+ years of experience in the field of Electronics, Embedded Systems, IoT & Industry 4.0 brings a wealth of knowledge and expertise to the table.

Mr. Chetan Kulkarni‘s customer-centric approach and experience with international clients have enabled to build pipelines worth millions of dollars.

Mr. Chetan Kulkarni have successfully handled IT-OT integration projects from lead generation to deliveries that have helped his clients to achieve their business objectives.

Mr. Chetan Kulkarni have presented technical papers at various forums.

Mr. Chetan Kulkarni is the winner in Emerson’s Technology Day 2011.

Mr. Chetan Kulkarni have also filed two invention disclosures, with one trade secret awarded.

Mr. Chetan Kulkarni is Bestowed with the following Licenses & Certifications :

https://www.linkedin.com/in/ch

Mr. Chetan Kulkarni can be contacted at :

LinkedIn | E-mail (Official) | E-mail (Personal)

About Elansol Technologies Private Limited

At Elansol Technologies, we empower industries to embrace the future of smart manufacturing and digital transformation.

At Elansol Technologies, we empower industries to embrace the future of smart manufacturing and digital transformation.

Elansol Technologies is a one-stop solution partner for businesses seeking to implement advanced Industry 4.0 technologies—driving efficiency, productivity, and intelligent decision-making.

Elansol Technologies specialize in:

● Industry 4.0 Consulting & Implementation

● Industrial Automation & IIoT Integration

● AI-Powered Vision Systems

● End-to-End Smart Factory Solutions

Elansol Technologies mission is to bridge the gap between the physical and digital worlds. From upgrading legacy production systems to deploying real-time autonomous solutions using AI, ML, and IIoT, our experts deliver scalable, innovation-led outcomes tailored to your operational goals.

With a client-centric mindset and a passion for solving complex industrial challenges, Elansol Technologies is on a journey to become a global center of excellence in Industry 4.0 transformation.

Elansol Technologies can be contacted at:

LinkedIn | Website | E-mail (Sales) | E-mail (HR)