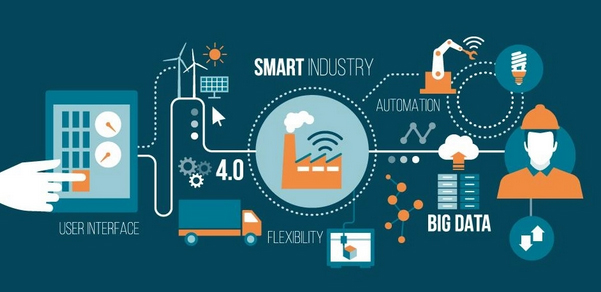

Industry 4.0 and Smart Manufacturing are revolutionizing production processes with advanced technologies like AI, IoT, and automation, optimizing efficiency, quality, and improving productivity enabling smart factories

Introduction

Industry 4.0 is revolutionizing the way companies manufacture, improve and distribute their products. Manufacturers are integrating new technologies, including the Internet of Things (IoT), cloud computing and analytics, and AI and machine learning into their production facilities and throughout their operations.

Industry 4.0, also known as the Fourth Industrial Revolution, is the current trend of automation and digital transformation in manufacturing technologies. It involves the integration of advanced technologies into the manufacturing process such as:

- Internet Of Things (IoT)

- Artificial Intelligence (Ai) and Machine Learning (ML)

- Robotics

- Big Data Analytics

Smart manufacturing, a key component of Industry 4.0, refers to the use of these technologies to create a more efficient and effective manufacturing process. By integrating these technologies, manufacturers can improve their production processes, reduce waste and costs, and create more flexible and responsive supply chains.

The benefits of smart manufacturing are many. First, it enables manufacturers to optimize their operations, resulting in improved productivity, reduced downtime, and increased throughput. Second, it allows for real-time monitoring and control of manufacturing processes, providing greater visibility into the production process and enabling rapid response to issues as they arise. Third, it can improve product quality and consistency by enabling tighter process controls and reducing the risk of errors.

In addition to these benefits, smart manufacturing can also enable more sustainable manufacturing practices by reducing waste and energy consumption. It can also help manufacturers to better understand customer needs and preferences, enabling them to create more customized products and services.

Overall, Industry 4.0 and smart manufacturing represent a significant opportunity for manufacturers to improve their operations, reduce costs, and create new business opportunities. As these technologies continue to evolve and mature, they will become increasingly important for manufacturers looking to stay competitive in a rapidly changing global marketplace.

Key Stats

The global Smart Manufacturing market is expected to reach $573.8 billion by 2027.

87% of manufacturers believe that Smart Manufacturing will lead to increased efficiency and productivity.

The use of Industry 4.0 technologies such as artificial intelligence, the Internet of Things (IoT), and robotics can lead to a reduction in production costs by up to 30%, according to a report by PwC.

A study by Deloitte found that 94% of executives surveyed believe that digital transformation is important for their company’s success, with 68% saying that they have started implementing Industry 4.0 technologies.

The implementation of Industry 4.0 technologies can lead to an increase in productivity by up to 30%, according to a report by Capgemini.

A report by McKinsey & Company found that the adoption of Industry 4.0 technologies could create up to $3.7 trillion in value for the global manufacturing industry by 2025.

The use of Industry 4.0 technologies can also lead to improved product quality and faster time-to-market, according to a report by Accenture.

According to a report by the World Economic Forum, the adoption of Industry 4.0 technologies could create up to 380 million new jobs worldwide by 2030.

The implementation of Industry 4.0 technologies can also lead to a reduction in energy consumption and greenhouse gas emissions, according to a report by the International Energy Agency.

Smart Manufacturing can reduce production costs by up to 30%.

69% of manufacturers plan to invest in Smart Manufacturing technologies over the next year.

54% of manufacturers believe that Smart Manufacturing will improve their ability to compete in the global marketplace.

The adoption of Smart Manufacturing technologies is expected to create 2.3 million new jobs by 2025.

Smart Manufacturing can reduce unplanned downtime by up to 50%.

80% of manufacturers have reported improvements in quality as a result of Smart Manufacturing implementation.

The use of IoT in Smart Manufacturing is expected to grow by 23% annually.

Smart Manufacturing technologies can help reduce energy consumption by up to 20%.

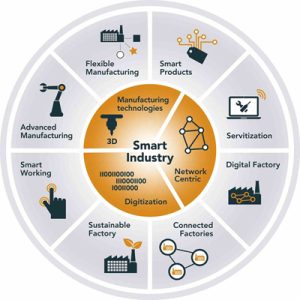

Industry 4.0, also known as the Fourth Industrial Revolution, is a term used to describe the current trend of automation and data exchange in manufacturing and other industries.

It represents a new era of technological advancement that combines traditional manufacturing with the latest digital technologies such as the Internet of Things, artificial intelligence, robotics, and big data analytics.

- Increased connectivity and communication between machines and devices, enabling greater automation and optimization of manufacturing processes

- The use of advanced sensors and analytics to collect and analyze data in real-time allows for more efficient and effective decision-making

- The creation of “smart factories” where machines, equipment, and processes are connected and can be controlled and monitored remotely

- The potential for greater customization and personalization of products, as well as increased speed to market and reduced costs

- The need for a highly skilled workforce with expertise in digital technologies and data analysis

- The potential for significant economic and social impacts, including job displacement and the need for upskilling and reskilling of workers.

- Industry 4.0 represents a significant shift in the manufacturing industry, leveraging digital technologies to improve efficiency, productivity, and competitiveness.

Smart Manufacturing is an advanced approach to manufacturing that uses cutting-edge digital technologies such as the Internet of Things, artificial intelligence, and robotics to optimize production processes and improve efficiency, quality, and flexibility.

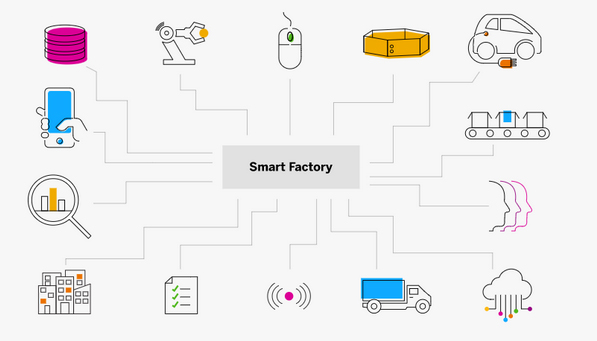

What is the Smart Factory?

A Smart Factory is a manufacturing facility that uses advanced digital technologies such as the Internet of Things, artificial intelligence, and robotics to optimize production processes and improve efficiency, quality, and flexibility. It is a key component of the Industry 4.0 movement towards greater automation and connectivity in manufacturing.

Key aspects of Smart Manufacturing include:

- The integration of data from across the manufacturing value chain to improve decision-making and drive continuous improvement

- The implementation of advanced sensors and automation technologies to enable real-time monitoring and control of production processes

- The creation of digital twins of manufacturing processes to enable virtual testing and optimization of production systems

- The development of agile and flexible manufacturing processes to enable rapid adaptation to changing customer demands

- Smart Manufacturing represents a major shift in the way that manufacturing is done, leveraging advanced digital technologies to create more efficient, flexible, and responsive production systems.

- It has the potential to significantly improve productivity, reduce costs, and enable greater customization of products to meet individual customer needs. However, it also requires a highly skilled workforce with expertise in digital technologies and data analysis to implement and operate effectively.

- Advanced sensors and automation technologies to enable real-time monitoring and control of production processes

- The use of data analytics and machine learning to optimize production processes and predict maintenance needs

- The integration of data from across the manufacturing value chain to improve decision-making and drive continuous improvement

- The implementation of digital twins of manufacturing processes to enable virtual testing and optimization of production systems

- The use of collaborative robots (cobots) to work alongside human workers to improve efficiency and safety

- Smart Factories are designed to be highly agile and flexible, able to quickly adapt to changing customer demands and market conditions.

- They are also capable of producing highly customized products at scale, using advanced technologies such as 3D printing and additive manufacturing.

The Smart Factory represents a major step forward in the manufacturing industry, leveraging advanced digital technologies to create more efficient, flexible, and responsive production systems.

Benefits of Smart Manufacturing

Smart Manufacturing offers benefits such as increased efficiency, improved quality, cost reduction, customization, flexibility, improved safety, and better decision-making. It enables manufacturers to operate more efficiently, effectively, and competitively in today’s fast-paced and rapidly changing market.

Smart Manufacturing offers a range of benefits for manufacturers, including

- Increased Efficiency: Smart Manufacturing technologies optimize production processes, reduce waste, and increase throughput, leading to higher efficiency.

- Improved Quality: With real-time monitoring and control of production processes, Smart Manufacturing technologies help identify and address quality issues quickly, leading to improved product quality.

- Cost Reduction: Smart Manufacturing technologies can help reduce costs through increased efficiency, reduced waste, and better use of resources, such as energy and raw materials.

- Customization: Smart Manufacturing technologies enable mass customization, allowing manufacturers to create highly customized products at scale to meet individual customer needs.

- Flexibility: Smart Manufacturing systems are highly agile and flexible, able to quickly adapt to changing market demands and production requirements.

Improved Safety: Advanced sensors and automation technologies can reduce the risk of workplace accidents and injuries, making manufacturing safer for workers.

Better Decision-Making: Smart Manufacturing systems provide real-time data and insights, enabling better decision-making and continuous improvement.

Smart Manufacturing technologies offer significant benefits for manufacturers, enabling them to operate more efficiently, effectively, and competitively in today’s fast-paced and rapidly changing market.

Challenges of Smart Manufacturing

The challenges of Smart Manufacturing include high implementation costs, the need for a highly skilled workforce, data privacy, and security concerns, the need for greater standardization and interoperability, and resistance to change. These challenges must be addressed to fully realize the potential benefits of Smart Manufacturing

Smart Manufacturing also presents several challenges that need to be addressed to fully realize its potential, including:

- Implementation Costs: The upfront costs of implementing Smart Manufacturing technologies can be significant, requiring significant investments in equipment, software, and training.

- Workforce Skills and Training: Smart Manufacturing requires a highly skilled workforce capable of operating and maintaining advanced technologies, which may require additional training and education.

- Data Privacy and Security Concerns: As Smart Manufacturing systems collect and analyze large amounts of data, there are concerns about data privacy and security, and the need to ensure that sensitive data is protected from cyber threats.

- Interoperability and Standardization: As Smart Manufacturing systems are highly complex and diverse, there is a need for greater standardization and interoperability to ensure that different systems can work together seamlessly.

- Resistance to Change: The adoption of Smart Manufacturing technologies requires significant changes to traditional manufacturing processes, which can be met with resistance from workers and managers who may be reluctant to embrace new technologies.

While Smart Manufacturing offers significant benefits, there are also significant challenges that need to be addressed to fully realize its potential.

Case Studies of Smart Manufacturing

There are several brands that have implemented Smart Industry Manufacturing 4.0 technologies and processes to improve their manufacturing operations. Here are some case studies:

General Electric has implemented Smart Industry Manufacturing 4.0 technologies such as sensors, big data analytics, and artificial intelligence (AI) in its factories to improve productivity, reduce downtime, and optimize its supply chain.

For example, GE’s Brilliant Factory in Greenville, South Carolina, uses data analytics and machine learning to predict and prevent equipment failures, reducing downtime by up to 20%.

Ford has implemented Smart Industry Manufacturing 4.0 technologies such as the Internet of Things (IoT), AI, and virtual reality (VR) in its factories to improve efficiency and quality.

For example, Ford’s Advanced Manufacturing Center in Michigan uses VR to simulate assembly processes, enabling workers to identify and address potential issues before production begins.

Caterpillar has implemented Smart Industry Manufacturing 4.0 technologies such as robotics, IoT, and AI in its factories to improve productivity and safety.

For example, Caterpillar’s Smart Iron program uses IoT sensors and data analytics to monitor equipment performance and identify potential issues, reducing downtime and improving safety.

Procter & Gamble (P&G) has implemented Smart Industry Manufacturing 4.0 technologies such as sensors and big data analytics in its factories to improve quality and reduce waste.

For example, P&G’s Baby Care plant in Mexico uses sensors to monitor diaper production in real-time, enabling workers to identify and address quality issues quickly and reduce waste.

These brands have demonstrated the benefits of Smart Industry Manufacturing 4.0 in improving efficiency, quality, safety, and sustainability in manufacturing operations.

The Future

The future of Smart Manufacturing looks bright, with ongoing advances in technology and increasing adoption by companies across various industries

Some of the key trends and developments that are expected to shape the future of Smart Manufacturing include:

- Greater integration of Artificial Intelligence (AI) and Machine Learning (ML) technologies to optimize production processes, reduce downtime, and increase efficiency.

- Increased use of the Internet of Things (IoT) technologies to create interconnected systems and enable real-time monitoring and analysis of manufacturing processes.

- The development of more advanced robotics and automation technologies that can work alongside humans to improve productivity and safety.

- Greater use of 3D printing and other advanced manufacturing technologies to enable rapid prototyping and customization of products.

- The adoption of digital twin technologies, which use virtual simulations to test and optimize manufacturing processes.

- The future of SmartManufacturing is expected to be characterized by continued innovation and technological advancements, leading to even greater improvements in efficiency, productivity, and cost reduction.

Conclusion

Smart Manufacturing is transforming the manufacturing industry by leveraging advanced technologies to optimize production processes, reduce costs, and improve quality. While there are some challenges to implementing SmartManufacturing, such as high costs and the need for a skilled workforce, the benefits are numerous, including increased efficiency, productivity, and flexibility.

American brands such as Ford, GE, P&G, and Caterpillar demonstrate the success of SmartManufacturing in improving operations and reducing costs. Looking to the future, ongoing advances in technology are expected to drive even greater improvements in Smart Manufacturing, enabling companies to remain competitive and meet the changing needs of consumers.

About the Author :

Mr. Deepak Wadhwani

Over 20 years of successful Technology & Marketing projects including enterprise web based software solutions, wireless engineering and e-commerce websites based on technology from Magento E-commerce, Artificial Intelligence, Augmented / Virtual Reality, Google, Php, Amazon, Oracle, Qualcomm, Sprint, Microsoft, WordPress / Woocommerce, Joomla, Drupal, PHP, Java and SAP business objects in over 50 countries.

Founded and Co-Founded Start-Up/Early Stage companies for wireless, mobile apps, software and web technologies.

Cutting Edge projects including Design / Development, Site Performance, Multivariate testing, SEO, Landing page optimization, Marketing automation, Ecommerce Marketplaces (like Etsy, Amazon) based on open-source and custom Magento ecommerce website platform.

Highly experienced wireless technology & online marketing consultant for major Fortune 500 companies including Sprint, Qualcomm, Intuit, Microsoft solution partner, Verizon, ESRI solution partner and UAI.

Designed and consulted for technologies in over 40 countries including Europe, Asia, North and South America.

Founder of a successful eCommerce, mobile apps and software Technology company for many top brands and major retailers.

Mr. Deepak Wadhwani can be contacted at :