BLOCKCHAIN THE BIG BROTHER FOR Eaas/Maas

Models

Abstract: –

A blockchain is a distributed database that is shared among the nodes of a computer network. Blockchain potentially could play a significant role in the validation of the Equipment as a service model (Eaas), or Machinery as a service model (Maas). These business models arrived quite some time back, however, there was a missing link on validating the billing data since it is entirely carried out on the running hour’s basis or the consumption basis, and blockchain as technology offers the perfect solution for the same. Today, the original equipment manufacturing industry and equipment users are in the middle of an ongoing paradigm shift. This shift is primarily due to the change arising out of the Equipment as a Service (EaaS) or Machinery as a Service (MaaS) business models. Maas/Eaas provides the avenue for the client to rent equipment or the output of the equipment, significantly reducing the upfront investment cost (which is called capital expenditure) and the other related cost like having the bare minimum inventory of critical spares which if not maintained could cause a lot of potential damage for the plant in operation and sometimes it may even cause the stoppage of the production.

How does blockchain technology act as a validator for the Eaas/Maas model

How does blockchain technology act as a validator for the Eaas/Maas model

For most industrial machine manufacturers, the term Equipment-as-a-Service (EaaS) is not a novelty. The classical sales model which involves one-off sales of capital goods (Capex) to recurring, revenue streams based on AMC or sales of spares, followed by complimentary services and occasional training, and seminars has been a common business model. However, with innovations spinning out at the speed of light, disruptive technologies like IIOT clubbed along with AIML and lastly validated decentralized ledger (blockchain) might trigger the extinction of the classical sales model.

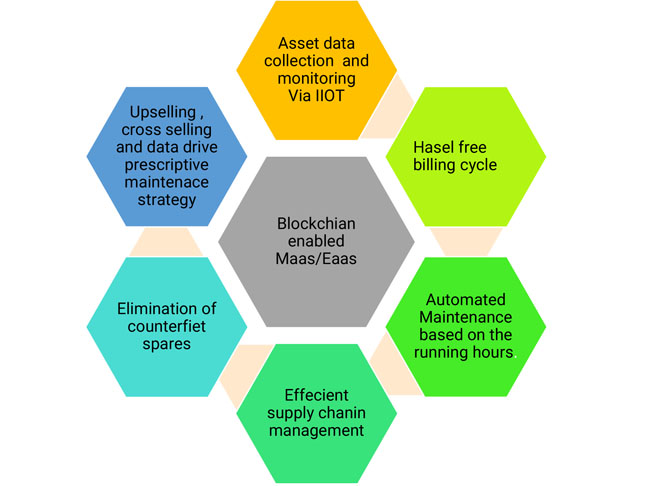

Illustration:-

How blockchain technology can increase the use of the Eaas/Maas model

Essentially without blockchain, the Maas/Eaas model will function, however more often it would require a lot of manual validations between the client and the supplier which would jeopardize the whole value addition this business model brings as the trust element is missing Imagine if this entire process is authenticated digitally by using blockchain, where a smart sensor via IIOT (Industrial internet of things) is deployed for accessing the realtime KPIs of the machinery and creating a transparency layer between the two parties, on the contrary, the cost would slightly increase but it would be more beneficial to both the parties, in the long run, as there are enormous benefits to reap from this. Lets us focus on them one by one

Primarily it would build trust and foster the relationship between the manufacturer and end-user, there would be no friction generated in the scenarios like a premature failure or performance-related issue or triggering the automated maintenance followed by mandatory replacement of the critical parts recommended by the OEMs as everything is driven by data, this approach would drive them towards synergy. Manufactures have better control in understanding whether the equipment is being used for the intended purpose and is it being operated at the recommended settings, parameters, load ratings and so on. Block chian enabled Maas/Eaas Asset data collection and monitoring Via IIOT Hasel free billing cycle Automated Maintenance based on the running hours. Efficient supply chain management Elimination of counterfiet spares Upselling, cross selling and data drive prescriptive maintenance strategy. The mandatory maintenance checks can be uploaded digitally via the ledger-based technology and the same data can also be matched against the trend collected via the smart sensors.

On the other hand machinery performance is shared live/ real-time with the manufacturer, which in turn will provide the manufacturers with tons of performance-related data, which becomes key in improving the overall performance of the machines since manufacturers have the first-hand data regarding the performance of the machines as is VS the to be designed one. For clients, CAPEX for the machinery procurement just moves out of the equation- thereby providing them with the options like expansion projects, or capacity enhancement. He wouldn’t even need to purchase the machinery, he just has to subscribe for the output of the machinery, thereby saving the initial CAPEX and secondly the inventory carrying cost for the critical spares ( as the maintenance shall also be under the scope of the OEM in this kind of business model) thus creating a win-win scenario for both the parties.

The most important benefit arising out of sharing validated data VIA a decentralized ledger is developing prescriptive Maintenance Strategies – One of the significant gains of smart manufacturing. Eaas/Maas provides opportunities for OEMs to design equipment and integrate prescriptive maintenance regulations within them right out of the box. In this case, the historical data collected from prior equipment uses and failures serve as the information needed to design and build a robust machine learning algorithm thus enabling a more realistic prescriptive maintenance strategy for the equipment. The spare parts procurement process can be planned with more precision thereby easing the burden on the supply chain.

Blockchain could be what iTunes was to the recording industry as it seamlessly helped in eliminating the piracy, similarly with a decentralized ledger data recording system, manufacturers have better control on the spares parts being supplied right from the sourcing point to the distribution point, thus providing the manufactures with much-needed ammunition to fight the world of organized counterfeit.

Lastly OEM has huge potential to tap into the upselling and cross-selling verticals because of the data at this disposal he could easily analyze the patterns which shed light on various elements such as the AS is operating condition vs TO BE operating condition, best practices followed, maintenance frequency and scheduling, inspections and the tools required for carrying out the inspections and so on, based on all these manufacturers can decide the right mix of the recommendations for performance enhancements and the right maintenance strategy for the equipment.

Summary: –

Equipment manufacturers cannot rely more on the conventional B2B sales model as most industry segments have seen a decline in asset margins as well as annual sales volumes, meaning OEMs are actively seeking new opportunities to gain market share with offerings other than pure asset sales and focusing more on the net value edition to the end-user. With the outburst of Eaas/Maas models, the solution was nearly there however the catalyst to drive this model further was perhaps missing and now with blockchain as a technology, it has the potential to fill the gap required. The primary reason why we are at a pivotal point toward more flexible business models today is Clients want to make their cash flow streams more predictable and are focusing more on developing an agile operating business model one way of doing this is by reducing the CAPEX expenditure. On the other hand, this model does increase the overall cost of the business model at both ends, but that can be easily traded off with many other benefits gained over the long run since it is going to be a win-win situation for both parties.

About the Author :

Mr. Prasanna Upadhyaya

Consultant – TriOcula Technologies

Prasanna is a Digital Manufacturing Leader with a proven track record of successfully executing Industry 4.0 initiatives with a focus on ROI and Sustainable manufacturing.

Prasana has strong data driven abilities and a clear understanding of Internet of things, business transformation process, ROI modelling, ERP implementation and integration, supply and demand side economies and its impact on manufacturing.

Prasana is Bestowed with the following Licenses & Certifications :

https://www.linkedin.com/in/pr

He can be contacted at :

Email : [email protected]

LinkedIn : pr

Twitter : https://twitter.com/pkupadhyay22

Also read his earlier article: