Industry4: explanation for the manufacturing eco-system

Introduction:

Industry4 shortened to I4 since its inception in 2011 by Federal Ministry of Education & Industry Germany and further explained as 4th Industrial revolution by Klaus Schwab in World Economic Forum reports as advent of cyber-physical systems. Industry1 was started by steam engine, 2 by electrification, 3 by advancement in computing and 4th revolution will be marked by integration of various new technologies between human and machines.

For manufacturing organisations, typically deploying lots of material and other resources e.g. automotive, the Industry4 is a game changer. Lets us analyse a typical value chain in automotive industry. The automotive industry plans its products looking at customer requirements, preferences and trends. The automotive OEMs capture whole lot of data from market, analyse and then make decisions. Typical product development cycle for an automobile is 3 years, though it has been constantly reducing since last decade or so. Typically all OEMs use platform approach wherein a platforms or a basic architecture of vehicle is used across several models & variants. The platform selection and design therefore is very critical for auto OEMs. Once platform architecture is decided, it becomes easy to plan further variants and models across it.

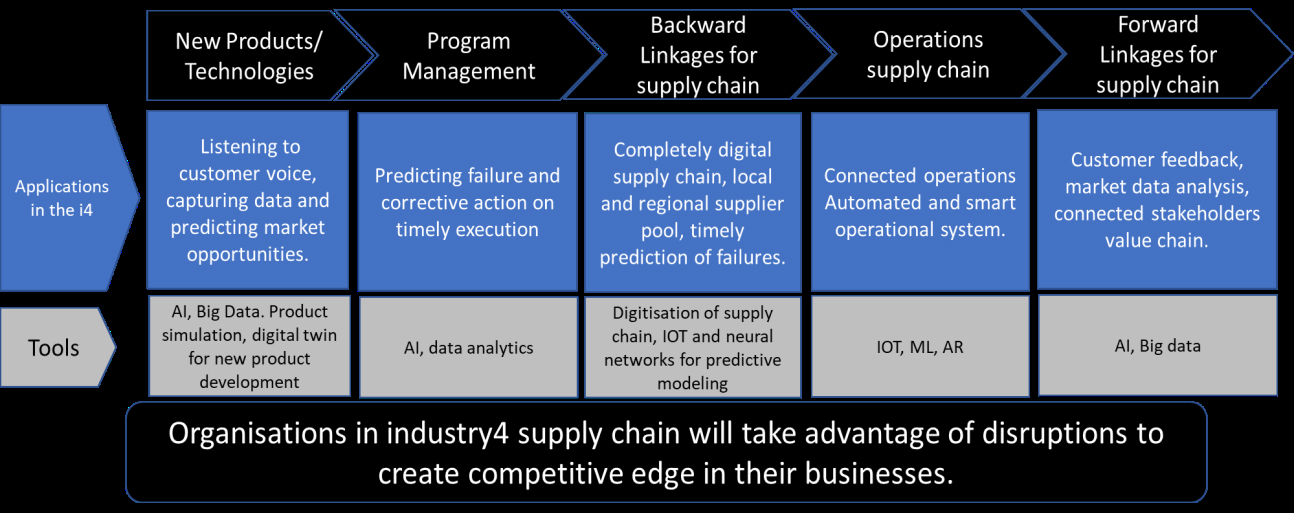

Fig1: Value chain of a manufacturing industry in Industry4 paradigm

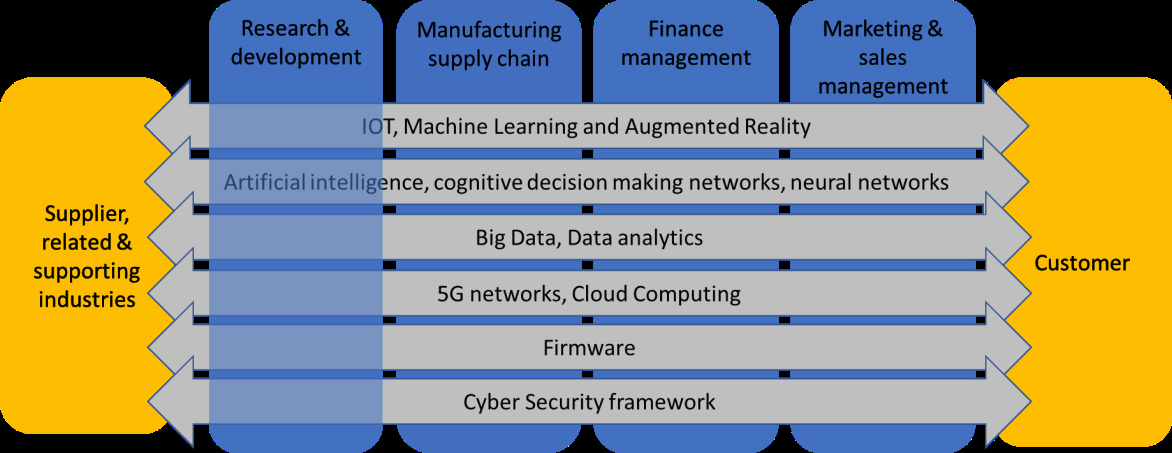

The industry4 framework uses tools like data analytics for capturing and collating data. In modern connected world, huge amount of data can be gathered from various sources. The users spend an enormous amount of time on connected devices like mobile phones, commerce (buying & selling on-line), gaming and entertainment. Each of these are rich source of data mining for the industry. User profile, pattern of use, choice and category of products, income and spending patterns provide necessary data to the companies planning products across its categories. The automotive OEMs track sales data, geographics, demographics across all vehicle categories. Once data is collected, filtered and analysed, product planning department can make decisions for their new product family. This is where Big Data and AI comes in. Modern AI tools can predict with high level of accuracy the product profile required for a particular category of buyer. The usage pattern, buyer behaviour and hundreds of such data points can predict the market movement for immediate to near future. These help in creation of market opportunities for the organisations. All the desired product level data are fed into the design and engineering funnel and final product architecture is decided. A clear example is the new age two wheeler market in India clearly shows a new sleek design of electric scooters using high level of automation, bio metrics and connectivity. Companies like Ather Energy, Ola have used these data points to create their scooters for the new age young population wanting a contemporary product and is willing to pay a premium price for it.

Once the product architecture, features and configuration is finalised, product development starts. This is a very critical phase of the value chain where in sourcing, make v/s buy, supplier selection, costing and value engineering comes in. All of these have to be accomplished in a definitive time line by the program managers. Critical to this is the time and resource management for the organisation. Organisations in Industry4 domain use previous program experiences, things gone wrong TGW), things gone right (TGR), lessons learnt to predict failure and take pre-emptive actions. The AI tools help here using learnings from millions of previous data points to predict failure and suggest alternate actions to avoid failure. Product development uses powerful technologies like Augmented Reality, Digital Twin where in OEMs could go to sample stage straight from design stage, tweaking the digital design thereby reducing time and capex.

Backward linkages of the supply chain are critical for production. The outsourced materials need to be bought at the right time, right quality and price. This is ensured through a completely digital supply chain. Recent global supply chain issues have highlighted the need to predict failure of supply chain immensely. After Covid we are seeing shortages of shipping container, shipping liners, chips and other electronics hardware items. This has called for realignment of supply lines of global players who have been largely dependent on China for many such products. Also from Just in Time, companies are moving to maintaining huge qty. of inventories. However such shortages may be short lived, leading to inventory and money blockage in the system of such companies. A digital supply chain with predictive analytics in place could predict shortages in advance and help companies take alternate actions for products and services. A clear example is Tesla who not only came through the recent crises but also sold more cars than last year. They could change their source of chips and rewrite the codes in advance to alter the supply chain. All this was done in a few weeks time, something which normally would take months for legacy companies like GM, Ford etc. all of whom have suffered massive production losses.

Fig2: Industry4 interlinkages in organisations eco-system

Operational supply chain is related to the operations wherein all materials get assembled to form the desired end product. This is where machines, robots and people work seamlessly to form a smart chain is related to the operations wherein all materials get assembled to form the desired end product. This is where machines, robots and people work seamlessly to form a smart digital factory. Industry4 uses IOT and ML where in machines talk to each other. Once the product planning department using market data analytics decides the product variants and numbers to be produced for each type, the manufacturing chain kicks in. The materials are pulled by the manufacturing system into the system from suppliers stores and processes e.g. welding, assembling, painting etc. start. The machines monitor their quality parameters seamlessly all by themselves. Production planning also decided which parts could be efficiently done using quick manufacturing techniques like additive manufacturing (3D printing). The machine algorithms prevent any missing parts, wrongly assembled part or non conforming parts going into the finished product. In case such a flaw detected the machines talk to each other and stop the line for a repair to set the part right or the bad part is rejected. The machine would learn to not repeat such a failure again. The entire work chain is designed to meet the cycle times, production qtys. in defined time lines.

Last link the chain is the forward linkages which are connections to the market. Automobiles are typically sold through dealerships-on line as well as off line. These dealerships keep track of customer visits, foot falls, queries giving important data points on product choices, placements and pricing. The data is back fed into the system to generate the market information system data product list which then goes into the supply chain.

Excellent example of i4: Covid19 vaccine development

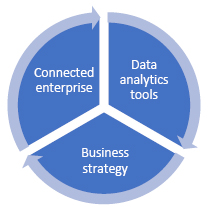

Covid19 rattled the entire world. The disruptions created by the virus was unprecedented with several global economies coming to stand still. The vaccine development is a tremendous success of modern scientific world. Scientists, doctors across the world worked on new ideas to develop the vaccine. They used mRNA technique first time successfully to develop the vaccine in under a year. Using high power technology sifting through billions of bytes of data, they were able to first identify the DNA of the Covid19 virus and then find the protein required for the anti bodies. In normal course of development, such a vaccine would take anything from 5 to 10 years of development, testing, clinical trials and approvals. The industry was able to fast track the development and start administration within one year! This is a great example of connected enterprise with integration of various technologies.

Fig3: Digital transformation of an organisation in Industry4

Conclusion:

Industry4 is going to be the next big force in the next decade. The concept has to be understood in totality as a complete system and not in isolation of parts. The entire system has to work seamlessly interacting with all the stakeholders. Industry4 is a complete paradigm shift from traditional industry practices of using machines and management systems. Industry4 calls for data management, smart automation, robotics and humanoids interphase. It encompasses the complete manufacturing universe with human, machine working in system sync. It calls for designing efficient manufacturing systems, using sustainable materials, optimised designs with least wastages. The system calls for new levels of skill sets as people need to be trained in the new eco system. The system design calls for high end interconnected systems of data networks, high speed data processing, neural networks and connectivity. At the user end the physical objects are interconnected in the universe talking to each other. Machine learning enables constant learning of these elements in the eco system. Hardware like sensors, GPS, high speed computing devices, Radar, LIDAR will enable the seamless connectivity in the system. The real time data collecting and analysis through cloud computing ensures decision making through network of tools. Key to implementation of i4 is creating a strategy for digital transformation of the industry. The selection of right tools for aligning business requirements and digital connectivity would be the key. For moderns organisations this would form the main part of business vision in the i4 world.

The indystry4 system is designed for significantly higher levels of productivity, efficiency and sustainability in the manufacturing system. However it must be understood that i4 is not meant for manufacturing alone. It cuts across all industries from automotive, engineering, agriculture, medical to service industry like fintech, energy and connected homes. The applications are enormous and possibilities are endless.

About the Author

Dr. Deb Mukherji, PhD

Managing Director

Omega Seiki Private Limited a member of the Anglian Omega Network.

Dr. Deb after receiving his PhD in Economics where he presented a detailed evaluation of the global competitiveness of the Indian auto-component industry, Dr. Mukherji has gone on to have a stellar and rewarding career in the automotive and related industries. He has worked with leading Indian as well as global companies such as Suzuki and Honda and has set-up greenfield plants across India, Mexico and Thailand. As a result of his experience and expertise, numerous foreign companies have developed and grown their India strategy under his guidance.

He can be contacted @

Linkedin : https://www.linkedin.com/in/deb-mukherji-ph-d-a0b4bb12/

Email : [email protected] , [email protected]