Enabling Journey Towards Demand Management 4.0 with Intelligent Workflow

Having a great forecast to start the supply chain planning cycle is every planner’s dream. A good forecast accuracy in Demand Management increases chances of having better planning result in all downstream planning processes like Supply Planning, Material Planning, Production planning etc.

However, the search for higher forecast accuracy had seen adoption of different approaches and tools for Demand Management in last five decades. For this article – we will divide this evolution in four logical phases:

Four Phases of Demand Management

Demand Management 1.0 (Enabled by Spreadsheet Solutions): The first phase of evolution of Demand planning process started with the invention of spreadsheets in 80’s and got its momentum in 1987 with the introduction of Microsoft Excel 2.0. While a technology of 80’s may look like an outdated one to many of us – the fact is Excel is still used as Demand Planning tool in many large and small organization till date.

Demand Management 2.0 (Enabled by ERP): This phase started as leading ERP vendors started offering basic Demand Management capabilities as part of their offering. Leading ERP vendor like SAP (as part of their R/3 suite) and Oracle started offering Univariate Statistical forecasting capabilities as part of their ERP solution as early as in 1992. ERPs had some capabilities of Demand Management (like Statistical forecasting) – but they were never an end to end Demand Management solution.

Demand Management 3.0 (Enabled by APS): This phase started with the emergence of Advanced Planning and Scheduling (APS) solution vendors two decades back starting with i2 Technologies and soon followed by Manugistics, Adexa and others. ERP vendors also came with their own APS Solutions. Statistical forecasting capabilities in these solutions are far more advanced. These solutions also came up with an end to end solution offering for Demand Management process in terms of Stat forecasting, Consensus Planning, Collaborative forecasting, and a defined way to release the forecast for downstream processes.

Demand Management 4.0 (Enabled by Intelligent Workflow and AI):This phase is the current evolution of Demand Management process where the focus is more on Intelligent workflow, modelling multiple data feeds, artificial intelligence / machine learning algorithms and predictive technologies for higher forecast accuracy.

The scope of our article will focus on the fourth phase of the evolution.

Why Demand Management 4.0

Now before we jump into detailing Demand Management 4.0 – let’s understand a bit more the need for this evolution. Why it was needed? Statistical forecasting technique for Demand Management was immensely popular in corporate world from late 80’s and almost every large company made it a part of their Demand Management process. But just to remind us – these were the days of Nokia phone (No smart phone with Social Media), B2B Commerce (No B2C – Every large company used to sell through their distributors), and new product introduction was a yearly event.

Things changed quite drastically in last decade. Social media became influential in shaping demand especially for consumer goods companies. B2C started evolving as another dominant distribution channel. New product release became an weekly phenomenon and Regular promotion of products became the norm of the day.

With these, drawbacks of statistical forecasting started emerging. Few of them are:

- Forecasting demand during promotion: Predicting short term demand during promotion is not possible with these tools as these are made for forecasting baseline demand.

- Forecasting new product demand: As there is no history for these products – getting a baseline forecast is a challenge. Tools for Demand Management 3.0 tried to address this with a rudimentary capability called Like profiling by copying history from similar product.

- Over dependence on one input – company’s sales history: Most companies used univariate statistical forecasting tools which used one input for forecasting – sales history – which is often not the right reflection of company’s demand (as if the company could not meet market requirement in the past – that never got reflected in history). The accuracy of history is a big question mark post COVID.

These necessitates new approach and tool for forecasting and demand management. These tools should be able to handle multiple inputs (beyond company’s sales history), have necessary algorithms to predict short term demand with higher accuracy and finally can learn of its own to improve the forecast over time. This resulted the emergence of Demand Management 4.0

Why Intelligent Workflow for Demand Management 4.0

Intelligent workflow is the central building block of Demand Management 4.0. Let’s understand – Why? Intelligent workflow is not one technology or algorithm – it’s a way of modelling the next generation Demand Management solution.

Traditionally – we always considered Demand Management is a process composed of a sequence of steps and often the steps look like this:

- Step 1 – Collect History

- Step 2 – Clean history

- Step 3 – Use this clean history to generate a baseline forecast using statistical tools

- Step 4 – Add Promotion and Manual adjustments on baseline forecast

- Step 5 – Create a Consensus forecast

- Step 6 – Release the forecast for supply planning

Depending on organization – these steps may vary – some more steps get added or deleted.

Now let’s take a closer look of this process as it is running in an organization – you will get a different picture.

- During history collection and cleaning – cleaned history need to be validated and approved before loading into forecasting application. Often this approval uses workflow technology – that need to be triggered to relevant stakeholder who has feel of data and can take a decision that whether the cleaned history is good enough for downstream processing.

- Promotion and Manual adjustment – This can happen by different stakeholders at different levels of organizational hierarchy. Again, workflow can play a key role here by triggering actions for different stake holder and subsequent approval.

- Consensus forecast and forecast release – Demand management is a consensus process by many stake holders in the organization from different departments (Planning, Sales, Marketing, Brand management etc) and workflow technology play a key role in triggering actions, subsequent validation and approval. Final forecast numbers need to be owned by Demand management process owner and need to be approved (facilitated by workflow) before release for supply planning.

This discussion helps us to understand why we believe that it is better to look at Demand Management process as a series of workflow instead of a sequence of steps.

Now once the need for workflow is understood – the next question is why these workflows need to be intelligent – what we mean by intelligent workflow? We had not talked about Intelligent workflow a decade back – why we are talking about this now? Let’s try to understand this with two examples

- Your company is running a promotion for the product that you launched last month. Consumers are talking great about your product in social media – Your sales are three times more than what you expected in first two weeks and you went out of stock. If your workflow engine could take this positive feed from social media and trigger a mid-month replanning of your demand estimate and trigger additional quantity request to your factories and suppliers – it would have been great – correct? This is where Intelligent workflow can add value – triggering action based on unstructured data –which can not be done by conventional workflow. A great value addition – Correct?

- Traditionally your company was habituated of using one forecast model for planning demand for a category. However, for last few months you are facing a problem – for certain months for certain categories it gives good result – however frequently for many forecast categories the result is very poor. Recently you had adopted Artificial Intelligence based Demand Management solution that came as a part of Intelligent workflow suite – this has a different approach – this try to understand the pattern of historical demand of your products – correlates this with lot of other external factors (like weather, Installed base, Macro economic factors etc) and give you a forecast result for next few months. You are seeing a good improvement in forecast result. Again, a great value addition – Correct?

We are sure by this time you have a good understanding of what we call Demand Management 4.0 and how Intelligent workflow is the central building block of this fourth phase of evolution.

Scope of Demand Management 4.0

One thing to remember here is – organizations can still use Demand Planning / Statistical forecasting solution (Solutions under Demand Management 3.0 or 2.0) for long term planning – the periods for which little is known with lot of uncertainties and a gross forecast is good enough. We recommend use Demand Management 4.0 solution for mid to short term i.e. for next 3-6 months – the period for which you need higher forecast accuracy – as this trigger all your downstream planning.

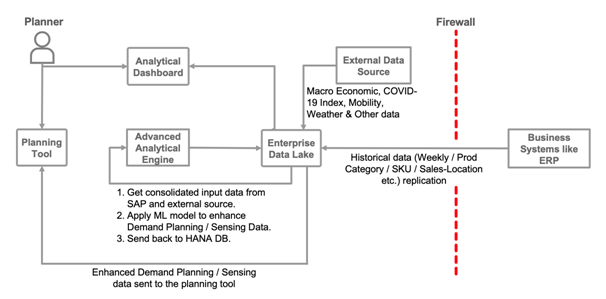

Solution Architecture of Demand Management 4.0 A representative high-level architecture of Demand Management 4.0 solution is shown in the figure below. Key building blocks of this architecture is: (a) Intelligent workflow and (b) Complete flexibility for its API based design.

Artificial Intelligence and Machine Learning plays an important role in this solution. We had used Python machine learning models for its wide popularity and specialized forecast algorithms for short term forecasting / demand sensing. Since a large volume of structured and unstructured data processing is involved in these cases, a robust and scalable computational environment is a must. Historical sales data along with weather, macro-economic numbers are gathered into a data lake solution and harmonized before applying the machine learning models. These models are first trained with the sample data set. In this case parallel processing is used to process high volume of data. Once the data is processed, depending on the target planning solution, data can be directly pushed into it for actual consumption by the planners.

Case study of Demand Management 4.0Proof of Concept for one of our clients

Recently we worked with one consumer goods company which was facing the challenge of huge forecast inaccuracy with their current Demand planning solution. We worked on a proof of concept with the single objective of using their short-term forecast accuracy. We adopted Intelligent workflow and Artificial Intelligence based solution. The solution provided them capability to:

- Include a wider array of pertinent data, such as weather, COVID-19 Risk Index, Mobility Index, social data from various social media, and opensource data from the CDC in their demand planning process. This allowed them to capture the correlations between these external factors and demand for their products, especially in the critical short-term horizon.

- Leverage machine learning algorithms to produce a more accurate short-term forecast.

- Use dashboard to get a visual sense of the impacts of these external factors on their demand

About the Authors

Mr. Rajesh Ray is an Associate Partner & Lead – Digital Supply Chain Practice @ IBM India Pvt. Ltd.,

He is an Engineer + M.B.A. and have 23 Years of consulting and domain experience in supply chain. He had worked in manufacturing and supply chain domain in ITC and Exide Industries. He started his supply chain consulting career with i2 Technologies followed by SAP AG in Germany and for last ten years with IBM. Rajesh is author of three books and 55 articles in different supply chain journals. He is honorary member of CII Logistics and SCOR society.

Mr. Rajesh is an IBM Industry Academy Member, Adjunct Professor of IIT Kharagpur, Principal Digital Supply Chain Architect – PMI, Global Logistics Innovation Lead – Nestle and is a frequent speaker in different supply chain forums.

He can be contacted at Mobile: + 91 9830678171 / EMail: [email protected]

Mr. Nilay Ghosh is an SAP Enterprise Architect, technology leader in IBM. He played many technology leadership roles like lead architect, design authority and currently leads the SAP Technical Development competency at IBM’s India Delivery Center. An IBM certified IT specialist, he helps in design, development, review of complex IT solutions using various matured and emerging technology technologies. He brings over 25 years of experience in IT industry including 20+ years in SAP. Nilay is a frequent speaker and holds a few patents.

He can be contacted at Mobile : +91 98300 17227 / Email: [email protected]

Also read my earlier articles