Breaking Time, Not Products : How AI Is Redefining Teardown Analysis in Manufacturing

For decades, teardown analysis has been a foundational practice in manufacturing. It helped organizations understand product architecture, benchmark competitors, identify cost drivers, and improve design decisions. But it came with an accepted trade-off: teardown was slow, destructive, and heavily dependent on manual effort.

You learned but you paid for it in time.

Today, that trade-off no longer holds.

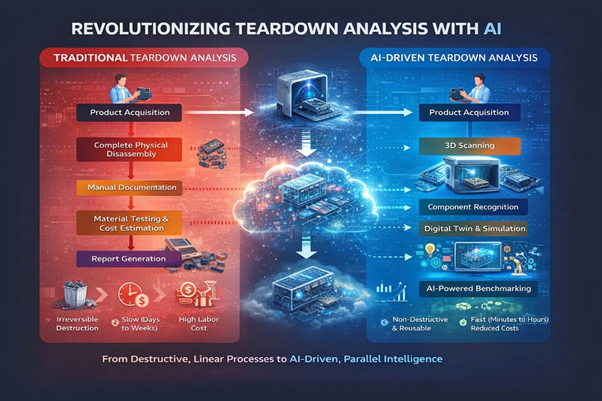

[See Figure 1: From Destructive, Linear Processes to AI-Driven, Parallel Intelligence]

Figure 1

A new generation of high-resolution scanners, cloud computing, and artificial intelligence is transforming teardown analysis from a physical, linear process into a digital, parallel, and intelligence-driven system. What once took weeks of disassembly and analysis can now be achieved in hours—without destroying the product.

This is not simply faster teardown. It is a fundamentally different way of learning.

From Linear Disassembly to Parallel Intelligence

Traditional teardown analysis followed a rigid sequence: acquire the product, dismantle it completely, document components manually, test materials, estimate cost, and finally generate a report. Each step waited for the previous one to complete. Insight arrived only at the end—long after key decisions had already been made.

Modern teardown analysis begins differently.

Modern teardown analysis begins differently.

A single non-destructive scan converts a physical product into a complete digital representation. From that moment on, analysis becomes software-defined. Component identification, dimensional inspection, internal defect detection, cost modeling, and performance evaluation can all happen in parallel—on the same dataset.

“The teardown no longer reveals intelligence after the fact; it creates an intelligence platform from day one.”

Instead of answering one question at a time, manufacturing teams explore many questions simultaneously.

Powerful Scanners Collapse Time

High-resolution industrial scanning technologies including 3D laser scanners achieving sub-millimeter accuracy and industrial CT systems that reveal internal geometries, now capture complete product structures in extraordinary detail. Assemblies, fasteners, internal voids, material transitions, and tolerances become visible without physical disassembly.

This collapses teardown timelines dramatically:

- No manual sectioning

- No loss of asset integrity

- No need to repeat analysis on new samples

One scan becomes a persistent digital asset that can be analyzed repeatedly as new questions arise. What once required coordinated teams and extended downtime now becomes an on-demand capability.

Time moves from being the constraint to being the advantage.

AI Turns Data into Insight

Scanning alone is not the breakthrough. Intelligence is.

AI-driven computer vision automatically recognizes components, classifies materials, and identifies patterns that would take humans days or weeks to detect. Cost models analyze how individual design elements influence overall product economics. Performance models evaluate how design decisions affect durability, reliability, and efficiency.

Instead of manual interpretation, manufacturing teams receive consistent, data-backed insight—faster and at scale.

This automation does more than accelerate analysis. It removes subjectivity, reduces human error, and enables repeatability across programs and product generations.

Field Failures: Faster Root Cause, Cleaner Answers

When failures occur in the field, time matters—but so does forensic integrity.

Traditional root cause analysis often introduced new variables through physical teardown, making it difficult to distinguish the true failure mechanism from damage caused during investigation. The process was slow, reactive, and disruptive. Worse, once the product was sectioned, it was destroyed forever.

Non-destructive scanning combined with AI changes this completely.

Products are analyzed in their as-failed condition, preserving forensic integrity. Internal cracks, fatigue zones, voids, and structural anomalies are detected automatically and compared against known-good baselines. The failed product remains intact—available for further investigation if needed.

“Root cause analysis shifts from inference to evidence. This is not just faster RCA—it is more reliable RCA.”

Corrective actions happen faster. Feedback reaches design and manufacturing teams sooner. And critical evidence is never lost.

Benchmarking Without Physical Teardowns

Perhaps the most powerful shift is how teardown analysis now supports benchmarking.

Instead of physically dismantling products to understand them, AI-powered digital twins enable simulation-based benchmarking across:

- Wear and fatigue behaviour

- Lifecycle performance and reliability risk

- Energy efficiency and system-level trade-offs

Manufacturing teams no longer ask: “How was this product built?”

They ask: “Which design decisions actually drive cost, quality, performance, and long-term reliability?”

Because the data persists, benchmarking becomes continuous. Each new product analyzed strengthens the intelligence base. Insights compound instead of expiring with a single teardown.

Benchmarking moves from a periodic activity to a strategic, always-on capability.

The Business Impact Is Immediate

The results are not theoretical. Organizations implementing AI-driven teardown analysis report:

- 40–60% reduction in teardown and analysis time

- Faster design iterations with real-time cost trade-off analysis

- Reduced dependency on destructive testing and repeat samples

- More focused R&D investment based on data, not assumptions

- Shorter feedback loops across the entire product lifecycle

Most importantly, organizations learn faster—and learning speed has become one of the most critical competitive advantages in manufacturing.

Teardown Analysis Has Changed Permanently

Teardown analysis is no longer about breaking products apart to understand them.

It is about:

- Breaking time barriers — from weeks to hours

- Breaking linear workflows — parallel intelligence, not sequential steps

- Breaking reliance on guesswork — evidence-based decisions at every stage

With advanced scanning technologies and AI, teardown becomes digital, predictive, and scalable. One product. One scan. Infinite insight.

“Manufacturers who embrace this shift will l decide faster, adapt sooner, and build smarter.”

And in today’s manufacturing landscape, that is the difference between keeping up and pulling ahead.

Mr. Prabhakar V

Digital Transformation Leader

TATA Technologies

Mr. Prabhakar V. is a distinguished digital transformation leader with over two decades of experience across industries such as automotive, sustainable energy, chemical, and HVAC. Currently associated with Tata Technologies, Mr. Prabhakar has consistently delivered transformative digital initiatives, driving significant impact and innovation across the value chain.

Throughout his career, Mr. Prabhakar has collaborated with global organizations to implement complex IT and digital programs, particularly in areas like process optimization, smart manufacturing, and automation. Known for his ability to leverage Industry 4.0 principles, Mr. Prabhakar empowers teams and organizations to embrace digital transformation and make data-driven decisions.

Passionate about knowledge sharing and mentoring, Mr. Prabhakar frequently publishes insightful articles on LinkedIn, covering topics such as AI, IoT, and the future of smart manufacturing. His thought leadership has garnered attention from industry professionals worldwide, positioning him as a respected voice in the digital transformation and technology innovation space.

Mr. Prabhakar also mentors students in supply chain operations, guiding the next generation of leaders in digital and supply chain transformations.

Mr. Prabhakar V can be contacted at :

Also read Mr. Prabhakar‘s earlier article :