Unwrapping WIP (Work-In-Progress) Manager to simplify WIP Tracking & Management for Manufacturers

Introduction

Managing work-in-progress (WIP) efficiently is a common hurdle for many manufacturers—especially small and medium-sized businesses that supply components or assemblies to larger industrial players. These companies often operate in fast-paced environments with tight margins, where accurate tracking of components and WIP inventory through the production process can make the difference between on-time delivery and costly delays.

WIP is the heartbeat of the production floor. It represents all materials and sub-assemblies that are neither raw stock nor finished goods—those in-between stages that, if not properly monitored, can disrupt operations and jeopardize delivery timelines. Manufacturers must know where each item is, what process it’s undergoing, and how soon it will be available for the next step. This information is critical not just for internal efficiency, but also for meeting customer requirements, particularly in industries where traceability is a contractual obligation.

Despite the increasing buzz around smart factories and Industry 4.0, most small and medium manufacturers still depend on manual WIP tracking. Advanced automation and integrated real-time systems are often too expensive, too complex, or simply incompatible with existing processes. As a result, many manufacturers continue to rely on spreadsheets, paper logs, and verbal updates.

These traditional tracking methods may seem manageable at first, but as volume increases and customer expectations grow, they become unreliable. Paper logs get lost, spreadsheets become outdated, and data inconsistencies creep in. Over time, the lack of structured visibility can lead to miscommunication, rework, production halts, and failed audits.

To bridge this gap without over-complicating operations, we developed WIP Manager—a practical, easy-to-adopt tool that brings structure to manual WIP tracking, ensures end-to-end traceability using tracker numbers, and simplifies reporting so manufacturers can make timely, informed decisions with confidence. Designed with the realities of small and medium-sized manufacturers in mind, WIP Manager doesn’t try to automate your factory-it helps you organize it better.

Understanding the WIP Challenge

The complexity of managing WIP lies in the fact that it’s always moving. Parts are cut, welded, assembled, painted, tested, and packaged—each step representing a hand-off, a change in status, and potentially a different physical location. In this fluid environment, staying up to date manually can feel like chasing shadows.

In addition to keeping track of location and status, manufacturers must be able to prove where a component has been and what processes it has gone through. This is especially critical in regulated industries where traceability is not optional but mandated.

The need for detailed, structured, and accessible information on WIP becomes increasingly urgent as production scales. But many businesses avoid digital solutions, fearing they require major investments in sensors, integrations, and infrastructure. This is where WIP Manager offers a valuable middle ground—digital organization with a manual touch.

The WIP Manager Solution

Our WIP Manager is a web-based application that helps manufacturers capture, monitor, and report on WIP activity using structured manual input. It’s designed to replace spreadsheets and paper logs with a centralized system that anyone on the shop floor can use.

Rather than promising AI, machine learning, or real-time automation, WIP Manager delivers clarity through simple but effective tools:

● Manual Data Entry – Operators or supervisors can log progress updates through an intuitive, browser-based interface. These inputs include job status, component movements, and process completions—recorded in real time, but entered manually by humans.

● Unique Tracker Numbers – Each batch or component is assigned a unique tracker number. This ID accompanies the item throughout its production lifecycle, building a complete traceability record without requiring sensors or tags.

● Cloud-Based Access – Data is securely stored in the cloud, allowing users to access WIP records and generate reports from anywhere—on the shop floor, in the office, or remotely.

● Structured Reports – Enables quick generation of WIP reports, production status reports, component history, and work-in-progress summaries. Reports can be exported in common formats such as Excel or PDF for audits, internal analysis, or customer communication.

● User Roles & Permissions – Managers, supervisors, and operators are given role-based access to ensure appropriate data handling and visibility across departments.

How our WIP Manager Works?

The simplicity of our WIP Manager is one of its greatest strengths. Implementation doesn’t require a dedicated IT department, hardware installation, or deep systems integration. It complements your current processes by providing a better way to log and analyze the same information you’re already tracking—only more consistently and with greater structure.

Here’s a typical workflow using WIP Manager:

1. Tracker Number Assignment: At the start of the production cycle, each work item receives a tracker number—either manually entered or auto-generated in the system.

2. Status Updates: As the item progresses through different workstations or processes, the operator logs its movement and completion status via the WIP Manager interface.

3. Data Collection: These updates build a digital footprint for each item, creating a timeline that can be reviewed later for analysis or audit purposes.

4. Reports & Dashboards: Supervisors and managers can access real-time summaries of what’s in progress, what’s delayed, and what’s ready to move. Data can be sliced by product, batch, operator, or workstation.

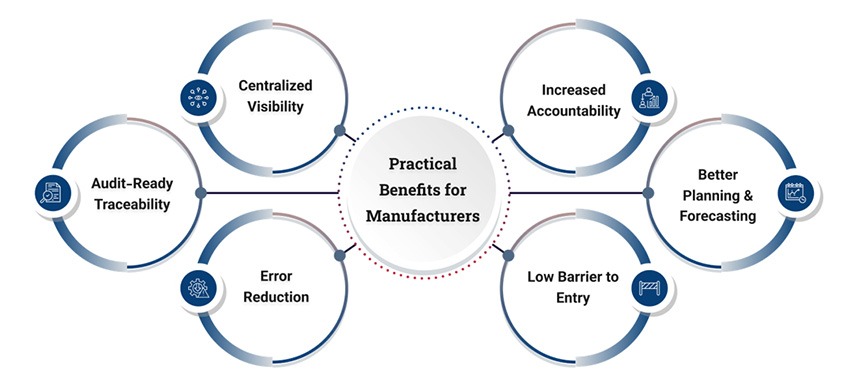

Practical Benefits for Manufacturers

1. Centralized Visibility

Having one system where all WIP data lives reduces confusion and improves coordination between departments.

2. Audit-Ready Traceability

Tracker numbers ensure every part or batch is traceable throughout its lifecycle—a key requirement in automotive, aerospace, and electronics manufacturing.

3. Error Reduction

Manual data entry is guided and structured through forms, reducing inconsistencies and omissions that are common with spreadsheets.

4. Increased Accountability

Role-based access and timestamps allow management to see who entered which data and when—supporting accountability and process improvement.

5. Better Planning & Forecasting

With up-to-date WIP status reports, planners can make informed decisions about scheduling, material needs, and capacity allocation.

6. Low Barrier to Entry

WIP Manager doesn’t require new hardware, integration with machines, or costly customizations. It’s affordable and fast to deploy.

Applications Across Industries

While designed to be industry-agnostic, WIP Manager is especially useful in production environments with complex or multi-stage processes. Common use cases include:

● Automotive Suppliers: Track component sub-assemblies across stages like machining, welding, and inspection, ensuring traceability for each lot.

● Aerospace Parts Manufacturers: Maintain detailed histories of each unit produced, including process timestamps and personnel accountability.

● Consumer Electronics: Monitor progress of partial builds and manage work queues across SMT lines or assembly cells.

● Fabrication Shops and Custom Job Orders: Keep tabs on one-off or low-volume custom orders where each part follows a slightly different path through production.

Why Choose our WIP Manager

The manufacturing software market is crowded with options promising total automation and integration—but many of these solutions are out of reach or out of sync with the realities of smaller operations. Our WIP Manager focuses on what matters:

● Ease of Use: No steep learning curve. Operators can start using it with minimal training.

● Affordable Value: Priced to fit small and medium-sized business budgets.

● Rapid Implementation: Go live in days, not months.

● Data Ownership: Your data is your asset, securely stored and easy to export.

● Scalability: Start small and expand as your operation grows.

Final Thoughts

In an industry that increasingly values agility, compliance, and effective inventory management, manual WIP tracking must evolve. While full automation might be the long-term goal for some manufacturers, many need immediate tools to bring structure, accuracy, and accountability to their existing processes.

WIP Manager offers that bridge—bringing the advantages of digital tracking and reporting to operations still grounded in manual workflows. It’s not about replacing people with machines; it’s about giving people better tools to do their jobs with confidence.

For manufacturers tired of chasing paperwork, correcting errors, or guessing where a job is on the floor, our WIP Manager offers clarity. With features that prioritize simplicity, traceability, and reporting, it delivers meaningful impact from day one.

Contact us today to schedule a personalized demo, speak with our Industry 4.0 specialists, or learn how WIP Manager can transform your production operations.

About the Author :

Mr. Saravana Kumar,

Vice President – Solutions,

Bevywise Networks Inc.,

Mr. Saravana Kumar is the Vice President of Solutions at Bevywise Networks Inc., where he is spearheading innovative IoT and Industry 4.0 solutions, including an industry-leading MQTT broker and IoT platform. His leadership ensures that Bevywise’s cutting-edge technology supports industrial and commercial IoT customers in seamlessly collecting, analyzing, and visualizing their data for enhanced decision-making, operational efficiency, and reliability.

Mr. Saravana Kumar is a highly experienced Solution Architect with a robusttechnical background and over two decades of expertise in delivering large-scale, complex solutions. Specializing in Big Data, SDN, AI, and endto- end project management, Saravana has proven success in executing and managing key projects, from RFP analysis to implementation. His career includes experience with top organizations like Zoho and WIPRO.

Mr. Saravana’s journey in the tech industry began with a role as a Software Engineer at AdventNet (now Zoho) from 2001 to 2004, where he contributed to the development of key applications. He then moved on to WIPRO, where he had a distinguished 16-year tenure, taking on roles with increasing responsibility and impact. As a Managing Consultant at WIPRO from 2015 to 2021, he led a team to build a next-generation management application for Fujitsu Network Communications, built on the Open Daylight Framework and utilizing Hadoop/Spark-based Big Data solutions.

Mr. Saravana was instrumental in managing customer requirements, overseeing a 100+ team, and ensuring successful deployments of customer-requested features.

Before this, Mr. Saravana Kumar served as a Presales Consultant and Software Architect at WIPRO, designing and delivering deployment solutions for Alcatel-Lucent motive applications, as well as leading teams through successful product demos and roadshows across multiple telecom vendors. Saravana’s expertise spans various domains, from network analysis and multi-vendor projects to building telecom solutions that integrate DSLAM technologies for global operators.

In addition to his work at WIPRO, Saravana took on roles such as Onsite Consultant, Software Architect, and Technical Lead, where he led development teams across Europe and Asia to build multi-vendor plug-ins and network diagnostic tools that were adopted globally by major telecom providers. Mr. Saravana Kumar is known for his leadership, cross-functional coordination, and successful integration of agile methodologies within his teams.

Mr. Saravana Kumar can be contacted at :

About Bevywise Networks Inc.,

Transforming Industries with IoT, AI, and Smart Solutions

Transforming Industries with IoT, AI, and Smart Solutions

At Bevywise Networks, we lead the charge in digital transformation, offering advanced MQTT-based IoT platforms, smart factory solutions, AI-driven manufacturing enhancements, and innovative educational tools. Our mission is to empower businesses and educational institutions to thrive in the connected era by providing tailored solutions that drive operational efficiency and academic excellence.

Our Expertise: MQTT-based IoT Platform: Enabling seamless, real-time communication across devices with scalable IoT connectivity, enhancing data exchange and system integration. Smart Factory Solutions: Revolutionizing manufacturing with intelligent solutions that optimize production, Traceability, Quality, Data Management, and operational performance.

AI Implementation for Manufacturing: Leveraging artificial intelligence to refine manufacturing processes, improve quality control, and provide plan annalysis and effective planning, driving smarter, more efficient operations.

Educational Tools: Developing state-of-the-art tools for colleges and institutions to enrich learning, streamline administration, and enhance educational outcomes.

Flexible Solutions: We offer both SaaS (Software-as-a-Service) and on-premise models to meet the unique needs of our clients, providing flexibility in deployment and management. Why Choose Bevywise Networks?

Expert Team: Our professionals bring extensive experience in IoT, AI, smart manufacturing, and educational technologies, delivering proven results across various industries.

Customized Approach: We craft bespoke solutions that align with your specific business or educational goals, ensuring optimal performance and impact. Commitment to Excellence: We uphold the highest standards of quality and integrity, continuously innovating to stay at the forefront of technological advancements. We are Open for Collaboration to enhance the world into much productive place.

Bevywise Networks Inc., can be contacted at:

X | FaceBook | YouTube | LinkedIn | E-mail

Also read Mr. Saravana Kumar‘s earlier article :