Microplásticos Improves Workers’ Learning Curve with Glartek’s Digital Solution

Glartek, a leading provider of innovative Connected Worker solutions powered by AR for the manufacturing and asset-intensive industries, has today announced the positive outcome of the introduction of its innovative digital solution to streamline Microplásticos complex assembly line operations. Microplásticos, a powerhouse in the production of high-quality dimensional plastic components, has registered significant improvements in training efficiency, error reduction, and overall productivity.

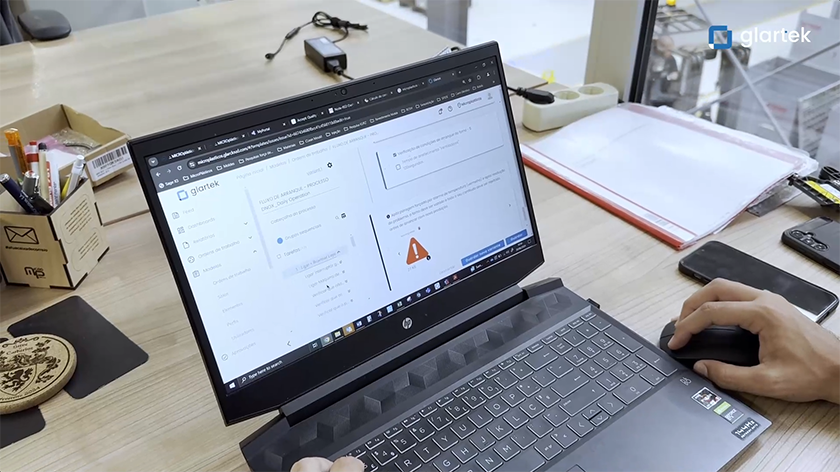

Microplásticos, which produces over 150 million pieces annually for global distribution, faced challenges with its traditional paper-based operating instructions. These printed instructions often became confusing and scattered, hindering the performance of operators. To address this, Microplásticos partnered with Glartek to digitize operative instructions, creating a model with different response flows and instructional images.

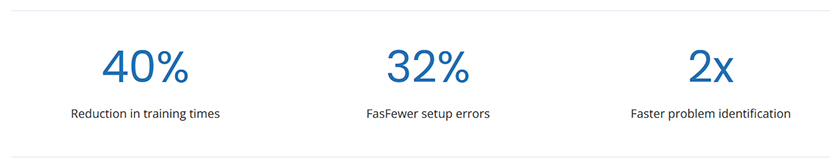

The implementation of Glartek’s solution has led to a reduction in downtime and an increase in productivity at Microplásticos. By mitigating errors, particularly during setup, the company has achieved more controlled and stable operations.

The digitization of operative instructions has greatly improved the learning curve for Microplásticos’ operators, enabling faster and more effective integration of new employees onto the factory floor. This digital solution has allowed the company to integrate processes and monitor actions in real time, providing a clear understanding of team interventions and process execution.

One of the most significant benefits of this collaboration has been the enhanced training of employees through fully digitalized lines. The ease of training new employees has been a standout advantage, as the digital solution has streamlined the onboarding process. Additionally, the digitized processes have facilitated the identification of problems on the lines, enabling the company to aggregate detailed data, identify patterns, and uncover opportunities for improvement. Furthermore, the flexibility of Glartek’s tools has allowed Microplásticos to easily create new processes and customize the solutions to fit its specific practices.

João Marques, Administrator at Microplásticos, stated, “This project is perfectly aligned with the continuous improvement strategy that the company has defined. It promotes innovation and operational excellence.”

This successful collaboration underscores Microplásticos’ commitment to innovation and operational excellence. By leveraging Glartek’s state-of-the-art technology, Microplásticos is well-positioned to continue delivering high-quality products while maintaining the highest standards of efficiency and safety.

“Glartek continues to support Microplásticos and implement solutions that allow it to face daily challenges and contribute to its digital transformation journey. We work side by side to adapt our solutions to their needs, to ensure efficiency in their activities and the best service for their customers.” Luís Murcho, COO at Glartek

About Glartek:

Founded in 2017, Glartek specializes in Augmented Reality (AR) solutions tailored for the industrial sector. Our core mission revolves around enhancing efficiency and safety within industrial processes. We achieve this by integrating Augmented and Connected Worker technologies, providing visibility, optimization tools, and reassurance for frontline workers. Our focus is on improving industrial efficiency and safety for frontline workers while fostering a culture of Continuous Improvement to drive Operational Excellence. Our customer base is diverse, ranging from asset-intensive companies like EDP to manufacturing firms such as Renault.

Glartek’s Social Media contacts :

LinkedIn | X | YouTube | E-mail

Also read Glartek’s earlier article: