An Introduction to Development in Technical Textiles & Medical Textiles

Technical Textile (TT) is a contemporary sector which is on a threshold for a mammoth growth. The world over is viewing this as an opportune sector to establish its own economics. India has set a target of 5.0 trillion for its economy attainable by 2024. The Ministry of Textiles (MoT) has contra to all its preceding practices set “ The Technical Textile Mission ” to make the TT as one big contributor (usually the existing industry demands a policy to its ruling government). Technical Textile (TT) is expected to contribute to the objective. India has given an impetus to manufacturing with promotions like Atmanirbhar (Self Reliant) or the productivity based incentive system and many of the MSME support schemes. They provide this unique & golden opportunity to script the change history for India.

TT is no longer a core Textile front but it has to wed with relevant participating sectors making it multi-disciplinary.Textile has an evolved engineering, technologies, processes, some innovations & operations that have seen the tests of time over millennia. The other relevant sectors are anxious to use Textile knowledge. They want to apply their advances in material science, refurbish the available machines, redo technologies & borrow the engineering and retrofit them with contemporary components, even probably connect them to the information technologies (IT/ AI) &to address the present day challenges of living. Textile base is the for future evolving sectors and transformations. Are we prepared for it? Textile also comes with a baggage of bias and adamant stiffness towards unlearning& relearning the new core domain to capitalise the above said opportunity. It limits to till the initial inertia is overcome.

The present power struggle for a new world order is witnessed by all. India is taking its chances to become a potential VISWAGURU. Can our ways provide more natural, ergonomic or economical solutions that are viable & sustainable? Can we win our own & also the world markets? India is the most dominant & Potent markets for the world for the present time. Our population is our challenge & also the greatest potential. We may be here as a game-changer by compulsion, but we cannot watch history craft without us, nor can we complain of the circumstances. There cannot be more opportune time than now.

The present power struggle for a new world order is witnessed by all. India is taking its chances to become a potential VISWAGURU. Can our ways provide more natural, ergonomic or economical solutions that are viable & sustainable? Can we win our own & also the world markets? India is the most dominant & Potent markets for the world for the present time. Our population is our challenge & also the greatest potential. We may be here as a game-changer by compulsion, but we cannot watch history craft without us, nor can we complain of the circumstances. There cannot be more opportune time than now.

LEADERSHIP CANNOT BE OUTSOURCED ANYMORE. LIVE IT BY YOUR OWN EXAMPLE.

Why Textile?

We can be say we have an expertise in fabric forming thought yarn or non-woven formation. Fabric forming could be broadly said to have a width & running length (rolled goods). We have learnt over millennia to handle finest fibre with mechanical prowess. We can easily adapt & interface with more contemporary sectors like Bio-technologies for Medical, Industrial, Environment or Marine; Material Science & Engineering to use modern materials derived as bio-absorbable polymers, natural extracts, Nano particles of titanium, carbon or ceramic as deposits or information technologies integrating Block Chain, IOTs & AI as wearable electronics just to name a few; to synergise with textile to provide for an end applications.

We know to handle tender fibres at high mechanical speeds, manage waste, form yarn, Interlace (Weaving, knitting, warp knitting, weft circular or flat knitting) or even create non-yarn fabric forming (non-woven, electro spinning). We have our head start with simple composites (Lamination, coating, fusing, blending etc.), doing Nano-deposits. We have been open & have a profound scope to experiment all the developments into the textile application or becoming a substrate or collateral / applied to support the cause of a solution. Textile imbibed the whole IT revolution thought its punch card system & the plastic engineering for sheets & Polymers found its initial source thought textiles. Technical Textile is the new eruption.

The textile industry has fragmented its process into a niche like Ginning, Spinning, yarn dying, knitting, weaving, fabric dying, printing, garmenting. The operations are discrete but have a structure to operate within a set organisation (Chain sequencing). The communication connects them for the desired delivery. TT is a new set of delivery which is coming back as a feedback to the process loop. The key is taking such a feedback into the input, altering some of the process for an output that can be viable &to make the business Sustainable. Integration of such feedback to the input has to be deciphered. It is a say of your deep conscious about the intent to be in this business. In India, we have seen some of the machines invested do not have a productivity and utilisation. Investments are repeated instead of working as a Team. This has repercussion of higher costs.

Beyond the aesthetics & fashion; TT expects performance with empirical values. One can start this journey from their position of strength, opportunity, weakness or threat. Reinforcing against weakness or threat can be an evolution. Working tandem with peer companies can reduce investment, integrating them with discipline of ethics, integrity or justice over IP values to synergies can be a desirable activity. Can we build an organisation structure between companies where the consortium can divide the investments in tandem and synergise the discrete process to capture the opportunity? It takes to build a new model of association, work on IP value, sharing the IP, teaming with the presumed adversary, building trust based on ethics, integrity & Justice. Academics have a role to document the phenomena as a data, provide literature support, writing some of the IPs for the industry & supporting the formation & documentation of innovation or supporting the industry for compliance with standards.

We have challenges to know “Who moved our Cheese” or equally to know the reverberating rut which we often fall and gaze at the phrase “I moved your cheese”.

We have a thinking mind but we often stay in our cosy space assuming all is well. When we decide to take actions;we fall out into someone’s recommended rut; away from your core strength and later call the opportunity as “The grapes were sour”. While judging the head has to be on the shoulder.

Synergy between all sectors in the right mix can be the true success story.

Textile is a twin sister to the Medical Industry. Past few decades the Medical Industry in India has evolved, to become the hub for global patients (Medical Tourism); however textile industry missed the co-evolution. The Medical Industry got its support by the collateral supplies from MNCs or imports. Local Textile Industry could not connect the Medical industry, until the recent pandemic and the logistical lock down. Today India has a new Drug & Device policy regulated by the CDSCO (Central Drug Standard Control Organisation).

The device policy has a simple take for the safety & efficacy of the device. They broadly classify to the 4 major group Viz. A Device is lowest risk, B – Moderate risk, C- High risk, D – Extremely high risk. You have to be complying to operational safety while delivering the device to the market. The primary need of any manufacturer is to get his Medical Device ISO (ISO13485) or the MDR (Medical Device Regulatory) quality process before applying for the Class of Device. The process should comply & manifest risks for patient & healthcare workers according to the classification.

There are no known ways to start but any beginning is a journey to the growth. The space needs investment, supplies, learning, testing facilities, validations, infrastructure suitable to pack Medical Device, engineering for the customised infrastructure, machinery or technologies, funding for innovation, entrepreneurship.

HOW TO GET THERE?

Visualising the opportunities can be impairing and looking up the vast opportunity can be perplexing. The answer is to “Get Started”. It could be starting on your strength, network, money or proximity to an idea or even market. You need to connect the dots.

The TT has numerous verticals to service like Agriculture, Packing, Automobile, Protective Textiles, Medical, Aerospace, smart textiles, Home, building, Sport etc.

You could choose to be a Marketer,Distributor and Dealer, Whole seller, Converters, manufacturer, entrepreneurs, lab, service provider or raw material supplier. Entrepreneurs or converters need machines that are easy on paybacks. Can Indian engineering provide solutions that come between a Europeans supply whose paybacks go beyond or an Asian machines that are challenged on quality.

A lot of harmonisations of law is being done (de-regulate & re-regulate) to get rid of bad laws & way in for a new. Textile being a very old industry has an elephant-chain effect, unable to break the old shackles. Government have many schemes for MSMEs to give impetus to the idea. Labour laws have to have a serious overhaul.

The collateral gains will be self-reliance in our manufacturing, saving of valuable foreign exchange, creating jobs for the youth.

Key take away are – New Model of associating & investing in tandem to be relevant in costs & Supplies. Teaming with core sectors to synergize, Listen to the input signals & take a rationale decision based on one’s inmost gutfeel, look for viable & sustainable solutions. Solve real life problems to make the market sustainable.

About the Author :

A Textile graduate from MS University, Baroda (Gujarat), MBA in Finance / Marketing from Bharathiar University (Coimbatore), a Drop out of PhD (Strategic Management). He has a versatile experience in building commercial models of new products; first-time industries &innovative technologies from ground levels into the market.

Worked thought reputed organisations like Arvind Mills (Ahmedabad), Precot Mills Ltd (Coimbatore) and Crocodile International Pte Ltd (Coimbatore) for the core textile tenure.

He has his exposure in

1. Medical Implant manufacture. Establishing Indian life saving device in Cardiology when he joined his college group friends to make & market the First Coronary Stents in India and also organise the clinical trials with the team at Sahajanand Medical Technologies. (1999-2004)

2. He undertook retail distribution of specialised TT fabrics of E.I. DuPont (Tyvek/Typar) for health & hygiene application. (2004-2005)

3. Created in-roads for Composite Hernia Mesh, Graft &Patches for W.L.Gore & Associates (USA). Provided for the opportunities to make Laparoscopy treatment more universal in Coimbatore. Became the highest selling Mesh in Asia for W.L. Gore in 2007-08.

4. His innovations into AMR, Nano coatings on surfaces & some medical devices got him his National award (runner up) in innovation i3 competition by DST (Dept. of Science & Technology) & CII (Confederation of Indian Industry) in 2010.

5. He organised & re-launched the Baby Friendly Hospital Initiative (BFHI) with his new model in association with UNICEF & IAP (Indian Academy of Paediatrician) as a Rotary President in 2009-10. It was to support the MDG (Millennium Development Goal) to reduce MMR rate (Maternal Mortality Rate).

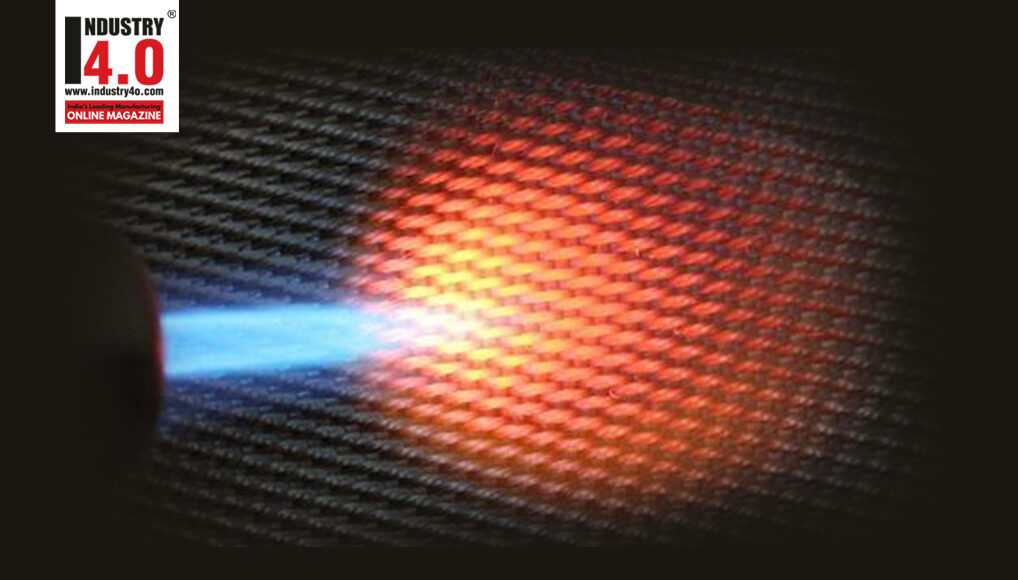

6. He established the Waste to Energy project for Turnw2e inc (USA) by putting up the first integrated plant to convert Waste to Syngas by gasification method. It was integrated with an evaporation system to recover the phenolic water by stripping the phenol, using a modified Multi effect evaporator (MEE). The project runs successfully for last 8 years at Surat (Sachin GIDC).

7. Present Endeavour – Splendour Medicare Technologies. To establish an SOP to make Textiles a Class Device by infusing innovative Engineering to provide an economical & sustainable solutions for domestic and probably world market. Sterilisation & Mechanised / Robotic automation are areas of focus for the future.

He can be contacted at :

Mobile : +91 94426 14445

E-mail : [email protected]

LinkedIn : sudarsan-rajagopalan-77401146

FaceBook : sudarsan.rajagopalan.3

Twitter : anusudar

Website : Splendour Medicare Technologies