Research & Results

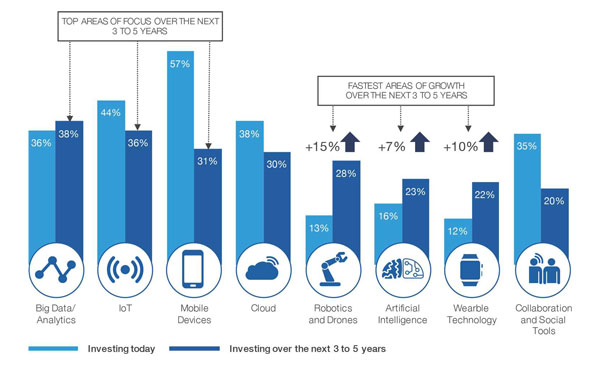

By 2026, more than 50% of large organizations will compete as collaborative digital ecosystems rather than discrete firms, sharing inputs, assets and innovations. – Gartner

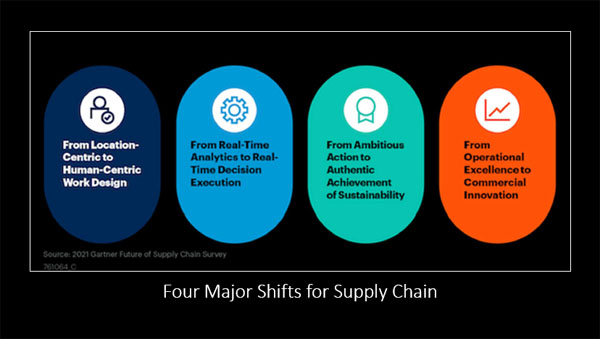

Across many functions of the end-to-end supply chain, there is an extensive and expensive set of business processes that require humans to perform manual tasks and decisions.

Customers are less and less willing to pay for these manual touch points and human interference. – Gartner

Our survey told us that integrated business planning (IBP) is eclipsing sales and operations planning (S&OP) as companies are looking to make their supply chains more resilient. IBP

offers the tempting promise of both streamlining inventory in the distribution network and enabling superior customer service. Aligning sales, marketing, and finance leadership is a

prerequisite to success as supply chains evolve to become collaborative supply networks that help enterprises – Forrester

Driverless trucks are already heading out to the highway, as shipping companies increasingly look to autonomous technology to meet rising demand for goods. The focus now: determining the best way to hand off trailers from machine to human. – Deloitte

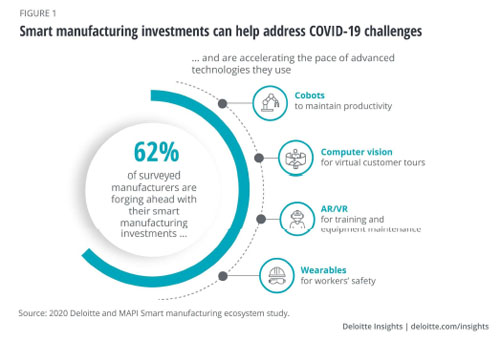

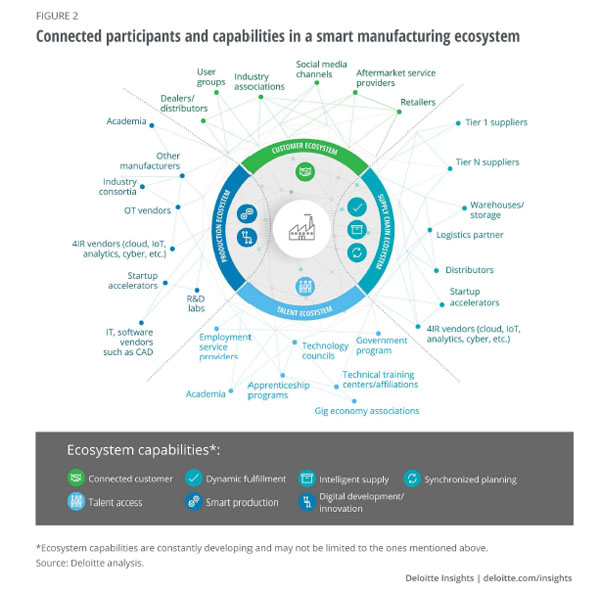

Pioneering companies are using advanced digital technologies, virtualized data, and cobots to transform supply chain cost centers into customer-focused, value-driving networks. – Deloitte

Over the next 18 to 24 months, we expect to see manufacturers, retailers, and others take supply chain transformation to the next level by optimizing their supply chain ecosystems for resilience and risk. Moreover, they will begin transforming their supply chains from traditional back-office cost centers into value-driving operations – Deloitte

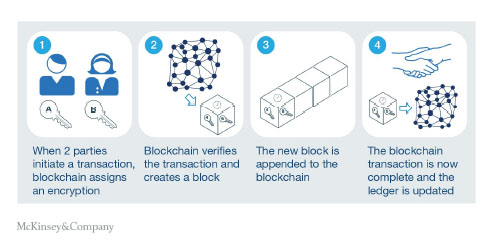

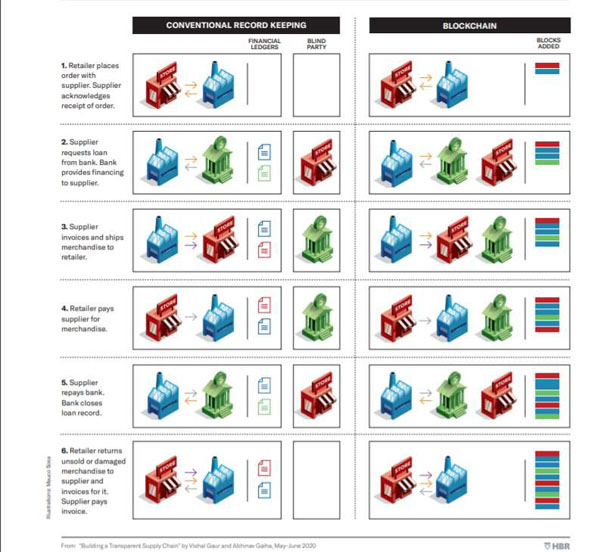

Blockchain in Supply Chain

- A blockchain is a distributed, digital ledger. The ledger records transactions as a series of blocks that are linked together sequentially in a chain. The ledger itself is spread across multiple computers that are each updated every time the blockchain changes.

How to create a blockchain transaction

Block Chain Benefits

- Blockchain can provide increased supply chain transparency, as well as reduced cost and risk across the supply chain. Specifically, blockchain supply chain innovations can deliver the

following key benefits:

Primary potential benefits

- Increase traceability of material supply chain to ensure corporate standards are met

- Lower losses from counterfeit/gray market trading

- Improve visibility and compliance over outsourced contract manufacturing

- Reduce paperwork and administrative costs

Secondary potential benefits

- Strengthen corporate reputation through providing transparency of materials used in products

- Improve creditability and public trust of data shared

- Reduce potential public relations risk from supply chain malpractice

- Engage stakeholders

Challenges and Limitations of Blockchain

- Low Scalability

- Implementation Challenge

- Shortage Of Talent Pipeline

- Private Key Issues

- Problematic Integration With Legacy Systems

- High Energy Consumption

- https://www.forbes.com/sites/forbestechcouncil/2021/11/22/introducingblockchain- six-limitations-for-enterprises-to-remember/?sh=70b6d318313f

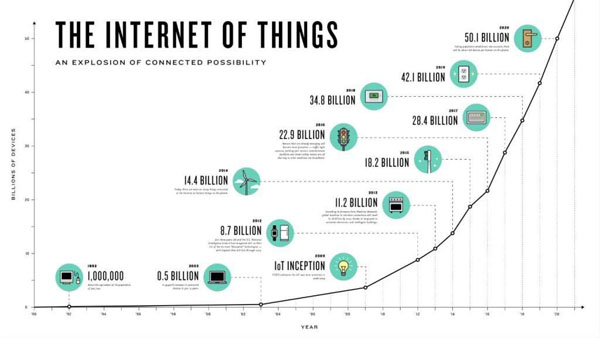

The Internet of Things

- Interrelated, internet-connected objects that are able to collect and transfer data over a wireless network without human intervention.

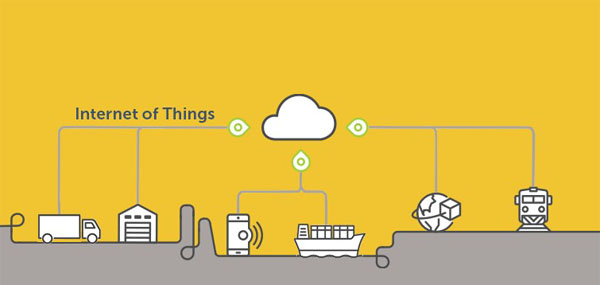

- In addition to providing more oversight in operations and transportation, it’s thought that the IoT can be used to improve warehouse management, fleet tracking, inventory control, and even technological and mechanical maintenance. IoT technology could even be used to create entirely smart warehouses and fleets, increasing the efficiency and accuracy of multiple areas of your supply chain.

- Depending on what kinds of IoT devices you use, you can use them in conjunction with other pieces of technology for even greater benefit. For instance, the information

collected by a sensor in one of your warehouses could provide valuable data that helps you automate other processes, such as forecasting and asset tracking. This high level of integration will be essential as the supply chain becomes increasingly digital. - In the Internet of Things, all the things that are being connected to the internet can be put into three categories:

- Things that collect information and then send it.

- Things that receive information and then act on it.

- Things that do both.

IoT Use Cases

- Authenticate the Location of Goods at Any Time

- Track Speed of Movement and When Goods Will Arrive

- Locate Goods in Storage

- Administer Goods Immediately Upon Receipt

- Farmers can use IoT devices to monitor soil moisture and decide the optimum time to plant or harvest

- Manufacturers can use IoT-enabled cameras to spot defects and reject faulty products.

- Chemical manufacturers can ensure that raw materials stay safe by monitoring and triggering an alarm if they’re exposed to high temperatures.

- Manufacturers can take advantage of “just-in-time” manufacturing by preparing to produce goods just as they’re scheduled to arrive

- Food retailers can monitor the temperature and humidity of goods in storage to ensure they reach stores in optimum condition

- Retailers can work with specialist logistics fleets to track products as they’re en route to distribution centers.

IoT Benefits

- Increases visibility and connectivity

- Improved asset utilization

- Better customer service

- Streamlined inventory and supply availability

- Safer and more reliable work environments

The Challenges of Using IoT in Supply Chain

- IoT devices rely on good network connectivity to function well. They need to be able to transmit their positions to GPS satellites and other types of IoT devices may require Wi-Fi, Bluetooth or other connectivity.

- They will not function as effectively in areas with lots of electrical or radio frequency interference.

- IoT devices also rely on being installed and powered properly

They should only be handled, attached or removed by trained people. - Important aspect of this is to use the right IoT device for the right job, as they can easily be damaged if they’re not used correctly.

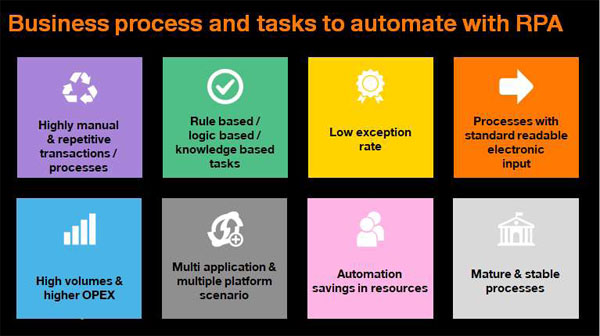

Robotic Process Automation (RPA)

- Robotic process automation is software that is used to automate high volume, repeatable tasks.

- Robotic process automation (RPA) allows an organization to deploy smart software bots that will automate common operational processes throughout the business.

- These bots are intelligent agents that can learn how specific tasks are performed and then repeat those tasks, eliminating human error and reducing overhead.

- Robotic process automation and software bots rely on machine learning and artificial intelligence to understand context and automate processes correctly. RPA also takes advantage of natural language processing (NLP) for better human interaction.

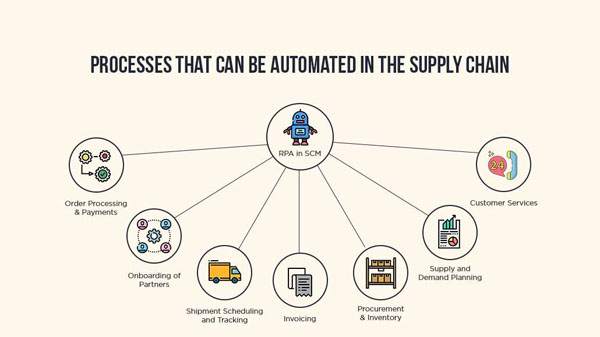

- Supply chain management (SCM) uses robotic process automation to automate common, low-value tasks, which streamlines operations in the supply chain and removes human error. RPA allows supply chains to scale up faster so that they can meet supply requirements as demand increases.

Artificial Intelligence and Automation

According to McKinsey, 61% of manufacturing executives report decreased costs, and 53% report increased revenues as a direct result of introducing Ai in supply chain. Further, more than onethird suggested a total revenue bounce of more than 5%. Some of the high impact areas in supply chain management include planning and scheduling, forecasting, spend analytics, logistics network optimization and more.

From making improvements to your assembly line to powering digital twin technology and everything in between, there are countless ways to incorporate AI and automation into your organization’s workflow. The key is finding tasks and processes that will help you save time or energy; often, the best tasks are time consuming, complicated, or extremely rote. By turning these kinds of tasks over to a robot or computer, you and your staff can spend more time on projects that only a human can do, giving you an even greater return on this investment.

Benefits of Artificial Intelligence in SCM

- ACCURATE INVENTORY MANAGEMENT : With their ability to handle mass data, AI driven tools can prove to be highly effective in inventory management. These intelligent systems can analyze and interpret huge datasets quickly, providing timely guidance on forecasting supply and demand. These AI systems with intelligent algorithms can also predict and discover new consumer habits and forecast seasonal demand.

- WAREHOUSE EFFICIENCY : AI systems can also solve several warehouse issues, more quickly and accurately than a human can and also simplify complex procedures and speed up work. Also, along with saving valuable time, AI-driven automation efforts can significantly reduce the need for, and cost of, warehouse staff.

- ENHANCED SAFETY : AI-based automated tools can ensure smarter planning and efficient warehouse management, which can enhance worker and material safety. AI can also analyze workplace safety data and inform manufacturers about any possible risks. It can record stocking parameters and update operations along with necessary feedback loops and proactive maintenance. This helps manufacturers react swiftly and decisively to keep warehouses secure and compliant with safety standards.

- REDUCED OPERATIONS COSTS : This is a big benefit of AI systems for the supply chain. From customer service to the warehouse, automated intelligent operations can work error-free for a longer duration, reducing the number of errors and workplace incidents. Warehouse robots provide greater speed and accuracy achieving higher levels of productivity.

- ON-TIME DELIVERY : AI systems can help reduce dependency on manual efforts thus making the entire process faster, safer and smarter. This helps facilitate timely delivery to the customer as per the commitment. Automated systems accelerate traditional warehouse procedures, thus removing operational bottlenecks along the value chain with minimal effort to achieve delivery targets.

- INTELLIGENT DECISION-MAKING : AI-lead supply chain optimization software amplifies important decisions by using cognitive predictions and recommendations on optimal actions. This can help enhance overall supply chain performance. It also helps manufacturers with possible implications across various scenarios in terms of time, cost, and revenue. Also, by constantly learning over time, it continuously improves on these recommendations as relative conditions change.

- ACTIONABLE ANALYTICAL INSIGHTS : Several companies today, lack key actionable insights to drive timely decisions that meet expectations with speed and agility. Cognitive automation that uses the power of AI has the ability to sift through large amounts of scattered information to detect patterns and quantify tradeoffs at a scale, much better than what’s possible with conventional systems.

Challenges of AI in Supply Chain

- System Complexities : AI systems are usually cloud-based, and require expansive bandwidth which is needed for powering the system. Sometimes, operators also need a specialised hardware to access these AI capabilities and the cost of this AI-specific hardware can involve a huge initial investment for many supply chain partners.

- The scalability factor : Since Most AI and cloud-based systems are quite scalable, the challenge faced here is the level of initial start-up users/systems needed to be more impactful and effective. Since all AI systems are unique and different, this is something that supply chain partners will have to discuss in depth with their AI service providers.

- The cost of training : Like any other new technology solution, training is another aspect which needs significant investment in terms of time and money. This can impact business efficiency as supply chain partners will need to work with the AI providers to create a training solution that is impactful yet affordable during the integration phase.

- The operational costs involved : An AI-operated machine has an exceptional network of individual processors and each of these parts need maintenance and replacement from time-to time. The challenge here is that due to the possible cost and energy involved, the operational investment could be quite high. Manufacturers would also need to replace these which can shoot up the cost of utility bills and could directly impact the overhead expenses of keeping them running.

Paperless Warehouses

Information is only as good as what you do with it. With data capturing and analysis at an all-time high, how do SCM leaders leverage that data? One way to ensure you don’t leverage all your data properly is continuing to engage in the use of an antiquated tool: paper.

In the global supply chain, nearly 3,000 parcels are shipped every second. Read that again, and by the time you’ve done so – another 10,000 parcels are out the door. There’s no way this type of big data can be leveraged properly by paper. Inventory management software (inventory automation software) is available and will revolutionize your business operations.

Paperless Warehouses

Benefits of paperless warehousing

Increase in Bottom-line

- Traditional or a paper-based warehousing requires a lot of labor, resources like paper, tedious and error prone paperwork which in turn leads to consumption of time; time is money.By reducing manual processes, it is possible to reduce operating costs, increase accuracy, and optimize warehouse space. All these factors would influence final profit.

Greater Accuracy

There is a lot of work in a warehouses including data entry where details of each action need to be recorded. Companies tracking orders and shipments with stationary computers or paper-based processes are unlikely to record events accurately or timely. In reality, the education level of picker or warehouse people is relatively low, which may lead to more inaccuracy. As a brand, you would be aware of the impact of a single wrong delivery fulfillment, end of a loyal customer, multiple penalties from marketplaces etc. Adopting a paperless approach

ensures the risk of mistakes are small and real time capture of all data.

Improved Visibility Throughout the Process

Keeping track of every order and shipment, inventory etc is not an easy task. With paper-based processes, data is tracked manually; so, user would always try to reduce the data capture processes. In a paper-based warehouse, the only method available for tracking productivity and performance is manual logs which is as good as the data each operator would have recorded. Going paperless with a cloud-based WMS would give real time visibility through various types of reports.

Higher Productivity

It takes a great amount of time to supervise and capture each process manually. As there is a high chance of error,

to rectify the error would also take a lot of time. As all the processes are time consuming, it reduces the overall productivity and better customer service. With paperless warehousing i.e. cloud based WMS and mobile app version of operation, a lot of time and errors are saved which lead to a higher productivity.

Environmental Benefits

There is no need to explain this as reduction in use of paper, would lead to a greater good of our mother earth by saving trees. With paperless system, companies would save a lot of warehouse space also.

Autonomous Trucking

One of the biggest names in autonomous truck technology was Starsky Robotics. It was at the forefront of putting autonomous trucks on the road. Its list of accomplishments is staggering. In 2016, it became the first street-legal vehicle to be paid to do real work without a driver behind the wheel. In 2018, it became the first street-legal truck to do a fully unmanned run. In 2019, it became the first fully unmanned truck to drive on a live highway. And now, even with these accomplishments, due to a lack of funding, the company shut down this year. The best guess on when we might see autonomous trucks delivering loads without drivers in the truck to take over in case something goes wrong in 2024.

This one is tricky. Forecasting the autonomous trucking industry has proven to be a risky business. The ROI will be monstrous. But it’s a slippery slope to invest in because there really is no due date involved with this new supply chain technology. Once it’s here though, the flow of goods and workflows of employees relying on logistics will never have been more profitable. Investments have poured in since 2015 or so, and while the technology is there – driverless trucks already exist and have completed road tests as early as 2019 – there are still a lot of hoops to jump through.

Extensive testing, pre-planned routes, and safety verification are all roadblocks for autonomous trucking. Companies like Starsky Robotics invested heavily into the trend but were too early, and their money dried up. But rest assured, when the time is right – autonomous trucking will dominate the industry. The ROI and sustainability are just too alluring to not succeed.

Hyper Automation

Hyper automation is ranked by Gartner as one of the 8 leading developments in supply chain technology trends for 2022 and beyond. Hyper automation is like creating a digital workforce that connects with different applications, analyze, and acts on unstructured data, makes decisions, and explores new possibilities for improvement of processes.

- This type of technology is all about other technology. What we mean by that is: hyper automation is a way to mix and match the best of a wide variety of technology’s offerings. It’s kind of like enterprise resource planning (ERP). Hyper automation can take your legacy platforms and implement recently developed tools that will allow you to use some of what you’ve already invested in, while also accessing the world of now.

- This will help organizations predict the demand in advance to plan inventory fulfillment.

- Predict the health of their units like software, computing platforms, internet connections, etc.

- Predicting the customer choices, eg: The demand for coffee flavor toffee is increasing so that company will increase the production of that product or launching a new product into the market.

- Gaining new insights with real-time data will help the decision-making process easy also it will delight your customers.

- This will help organizations predict the demand in advance to plan inventory fulfillment.

Digital Supply Chain Twin

Simulations are indispensable but real world simulations are expensive. Therefore companies that need to learn fast (e.g. self-driving car manufacturers) heavily rely on simulations. Digital twins enable companies to simulate their shop floor or their entire business to identify optimization opportunities.

Today, businesses use digital twins in numerous ways from product development to operational performance improvement. Though the market for digital twins is relatively small (4 billion dollars in 2019), it is expected to grow to 36 billion dollars by 2025 at a CAGR of 38%. Increased digitization and IoT adoption are making it easier for businesses to build accurate digital twins and drive adoption of the technology.

Digital Twin Model Builders

- A digital twin is a virtual/ digital replica of physical entities such as devices, people, processes, or systems that help businesses make model-driven decisions. The purpose of a digital twin is to run cost-effective simulations

- A supply chain digital twin is a virtual simulation model of a real supply chain used to analyze supply chain dynamics and predict process success. DT models benefit from real-time data and snapshots of planned and released work orders, sales orders, pending approvals, demand and supply. The data is gathered from sources like:

- IoT devices (e.g. sensors)

- Logistics and transportation databases

- Operations databases

- Vendor information (e.g. CRM data, bills, invoices)

- User experiences (e.g. online reviews, customer service tickets)

Digital Twin Benefits

A digital twin can help businesses understand patterns, and model the outcome of modifications in different processes for:

Improving design tests of supply chain process:

DT models in supply chain moderate business continuity and transformation risks before they occur by outcome prediction. The models enable calculating benefits, savings, and potential ROI before the transformation of the process occurs. For example, a business generates DT models to redefine the global operations by simulating various scenarios that include data related to manufacturing, inventory and product distribution.

Monitoring risk and testing probabilities:

DT allows supply chain companies to test and discover the best course of action for emergencies, and try different scenarios in a virtual environment, significantly improving organizational stability.

Use cases of digital twins in supply chain

Some of the areas of supply chain digital twins can be applied to improve include:

- Planning transportation and facilities

- A digital twin can assess how changes in demand and supply affect the supply chain’s physical locations and supporting system while delivering products and services to end customers. By leveraging real-time data, digital twins enable supply chain management to better plan transportation resources.

- Optimizing inventory

- A supply chain digital twin can input data from demand forecasting processes to avoid stock-outs and minimize overall costs of production and warehousing. As a result, it addresses the “single-echelon” challenge (optimizing inventory in a single warehouse) and the “multi-echelon” challenge (optimizing inventory across the entire network).

- Predict the performance of packaging materials

- When applied to packaging, digital twins can simulate package shapes and packaging material in order to test for defects before deploying them, which does not only decrease the financial but also environmental cost.

Challenges of supply chain digital twins

Data quality

To generate digital twins of supply chain systems, the data that is extracted from various sources should be cleaned and wrangled to fix duplications and missing data. Though data quality is crucial part and it seems challenging, companies can leverage data transformation tools and data mining tools that use AI and machine learning (ML) to enhance data quality.

Technology adoption

There are variability in business practices with regards to the level of technological embracement. In some sectors, like agriculture, product-technology is complex and the infrastructure is not always clear. However, more businesses on the way to transform by adopting new technologies, promising that the issue might be tackled down soon.

Supply Chain Security & Governance

Track-and-trace solutions, advanced RFID capabilities, and smart packaging are emerging tech trends that will have major impacts on security, governance, and risk management for supply chain leaders and supply chain partners. This is a global trend that has its toes in the water but will dive head-first in the coming year-plus. Furthermore, accounting is an area of business that will soon be automated – allowing for less oversight, proper allocation of resources, and optimal governance of your supply chain. Supply chain risk just got a lot less risky, thanks to these emerging technologies.

Robotic Automated Storage and Retrieval

In the last few years a form of goods-to-person automation has come to market. These “robotic shuttle systems” are a hybrid of traditional shuttle systems and free roaming robots. There are a handful of providers currently offering solutions that fit into this categorization. And each one approaches the problem in a different manner. However, they all offer the benefit of high storage density and a high degree of flexibility due to the dynamic movement of bots. This bot agility removes throughput and sequencing constraints, providing increased productivity potential. These solutions align with the operational needs of many industries. However, they are coming to market just as demand is accelerating for same-day fulfillment of online orders. This spike in demand is especially prevalent in egrocery fulfillment. These solutions may be fulfilling your next online order of apples and bread.

5G

- 5G is the fifth generation of wireless technology. With 5G, you’ll see exponentially faster download and upload speeds. Latency, or the time it takes devices to communicate with each other wireless networks, will also drastically decrease. The benefits are clear for consumers that want to download movies on their smart phones and watch them. But will there be benefits for supply chains?

- The theory is that as more and more devices throughout the supply chain and manufacturing process become part of the ‘Internet of Things,’ they will produce an incredibly rich data stream that will send signals in realtime to trigger a wide variety of events. For example, using a 5G network, a parts tote could communicate that the tote is 80% depleted for this SKU which would trigger a re-order of the necessary parts. This would be a trigger across the supply chain which would result in warehouse movements, maybe LTL, consolidation, and finally distribution and delivery of re-supplies.

- According to Qualcomm, 5G is foundational to further innovation, which is certainly the case when it comes to supply chain management. Gaining real-time data is difficult when suppliers lack connectivity. Supply chain visibility becomes spotty without 5G. And third-party logistics is made possible through the use of 5G because it elevates mobile networks through multi-Gbps peak rates, ultra-low latency, and massive data capacity. High-level performance, increased efficiency, and new user experiences become available when 5G interconnects people, machines, objects, and devices. 5G further offers the power to:

- Extract larger amounts of data concerning location, temperature, pressure, and other information that is critical in the end-to-end supply chain

- Ensure uniformity of information sharing with all stakeholders

- Resolve issues that would otherwise be aggravated with time delays

- Understand exactly where raw materials come from

Digitization

Digitization refers to the practice of putting information into a digital format. When it comes to securing the future of the supply chain, digitization is non-negotiable. Experts believe that effective digitization can make your entire supply chain more streamlined, mobile, and dynamic – all of which are highly beneficial for your organization’s bottom line.

If you haven’t gone fully digital, keep in mind that the transition can be challenging. You have to find the right kind of technology to meet your organization’s needs, implement it correctly, and work out any internal difficulties. However, you can’t afford to not digitize. It’s already the present, and it’ll only become more integral to the supply chain in the future. If you are unwilling or unable to digitize your supply chain, you’ll likely struggle to succeed going forward.

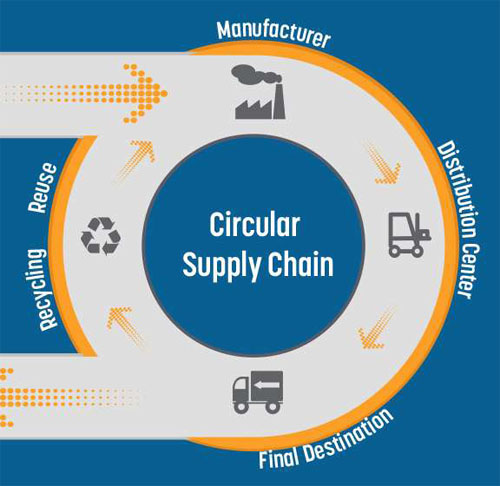

Circular Supply Chain

- Traditionally, supply chains have been thought of as linear: starting as raw materials, goods flow in a straight line through the supply chain until they are a finished, disposable product. Now, more people subscribe to the idea of a circular supply chain, wherein raw materials, and even discarded products, are recycled and re-introduced into the manufacturing process.

- The circular supply chain model certainly helps with sustainability efforts, but it also has economic benefits for your organization. The earth has a finite amount of raw materials, and as they become more scarce, they will increase in price. Further, if you’ve already paid for materials or a product, but you aren’t able to use it for its intended purpose, you won’t waste money on something you’ve already purchased that’s still perfectly useful. You stand to save more money on reduced storage, transportation, and administrative costs, too.

- Strengthened professional relationships and increased reliance on technology (including AI and IoT) can also help your efforts to operate under a circular supply chain. If you and the other people and companies you work with are willing to share information and resources, you can further decrease waste and keep more materials in production. Additionally, with the right technological solutions, you can stay updated on the current state of your materials and products in real-time.

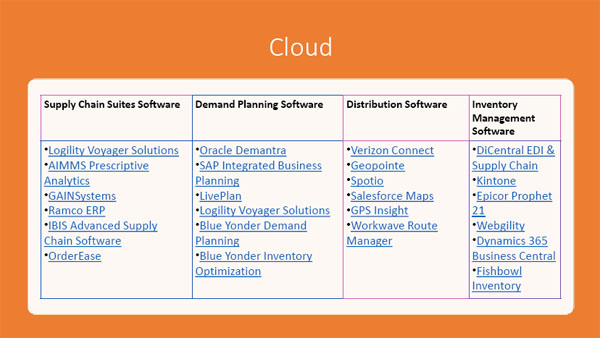

Cloud-Based Solutions

- Similar to digitization, cloud-based software solutions are the way of the future in supply chain management. Traditional and localized supply chain management solutions won’t cut it. To stay competitive, you need accurate, agile, and accessible solutions for your organization.

- Software-as-a-Service (SaaS) models are particularly useful for supply chain management. Not only is SaaS reliable and secure, but it’s highly efficient and convenient. All of your organization’s data is stored in the cloud, and you and your team can get the information you need at any time, from any

place. With a global and digital supply chain, the efficiency provided by SaaS solutions is crucial to support your organization as you move into an increasingly fast-paced future. - As these trends continue to evolve, so too will the art of supply chain management. New developments will lead to unforeseen consequences, both positive and negative. To stay up-to-date and position your organization for success, you’ll have to attempt to anticipate and continue to adapt to these still-unknown changes in the supply chain.

Cloud

At any point during the end-to-end supply chain, companies track materials and products, get real-time updates, and inform customers of the status of an order. This is all made possible with cloud computing. Cloud-based solutions enhance a number of areas such as data storage space, integration, security, and information sharing. Activities and processes are streamlined between multiple devices and an enterprise of software users.

Autonomous mobile robots (AMR) :

Supply chain giants like Amazon have discussed the use of AMRs in the past, but they haven’t been widely adopted across the industry. While warehouse management systems will continue to organize things like scheduling loading and unloading, AMRs may emerge as a tool to optimize the picking process.

Truck collaboration:

Truck manufacturers and shippers are preparing for a recession and would be wise to invest in manufacturing and collaboration software systems. More advanced systems allow for trucking companies to strengthen the way they monitor the market, automate processes, and cut costs.

Distributed inventory :

Current inventory software isn’t providing the analysis needed to keep up with distributed inventory, making it harder for companies to keep up with innovative shipping demands. A tool called distributed inventory flow forecasting (DIFF) predicts the flow of materials, enabling businesses to maximize the order fill rate and maintain reduced inventory.

Driverless vehicles and drone delivery:

Driverless and drone delivery options provide companies with a solution to a variety of issues. Not only does this lower costs by lowering the amount of human intervention, but it also gives more access to remote and hard-to-reach rural areas. While some have been skeptical about this technology in the past, it may be a positive solution for the future, particularly in light of the worsening shortage in available human drivers.

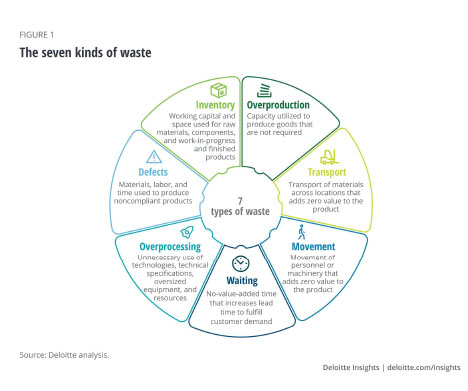

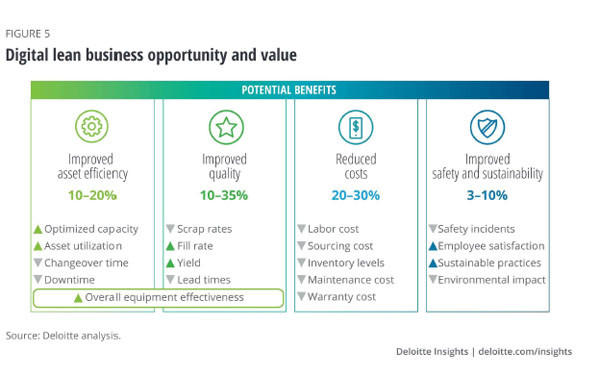

Digital Lean Manufacturing

- The application of lean principles within a manufacturing context extends back several decades, even if the essential idea of reducing waste and driving efficiencies existed long before the term “lean” was coined. But lean as we understand it today has coalesced into a set of principles that has transformed manufacturing.

- For their part, in more recent years, Industry 4.0 digital and physical technologies have made possible new accomplishments of speed, cohesion, flexibility, and automation that have forever altered what production looks like. Advances in robotics, materials, and artificial intelligence are all poised to be the future vanguards

- As a result, digital technologies and lean principles are intersecting in what is commonly termed “digital lean”—which can be a powerful combination of timeless lean principles and constantly evolving digital technologies to decrease waste and variability in processes.

Smart Factory and Manufacturing

About the Author

Mr. Bala Subramanian is a business leader with more than 20 years’

experience in client partnering to deliver technology, consulting and

outsourcing solutions. Responsible for regional business, strategic

initiatives, client relationships and for providing engagement oversight

for large scale transformation programs.

Affluent in Next Generation technologies and industry trends. Driving major strategic initiatives at global level to build Cloud, Technology and Industry capabilities & solutions using Cloud ERP, IOT, Block chain, Analytics, Robotics process automation that is driving new business and

revenue for the organization.

In-depth background in complex technology program delivery and steering partner engagements. Possesses diverse experience across US, Europe, Middle East and Asia Pacific market segments.

Has a proven ability to sell, lead, and deliver Global Transformation Projects with increasingly large client footprint and scope. Extensive experience implementing solutions in Supply Chain areas like Inventory, Procurement, Sourcing, Order Management, Manufacturing, Planning, Maintenance , WMS and Logistics .

Worked with Godrej & Manufacturing, Almoayyed International Group, KPIT Cummins Infosystems, Wipro, Oracle, Deloitte as an employee in the past. Currently working as Vice President- ERP Practise with Evosys Global.

He can be contacted @

Email : [email protected]

Mobile : +91 99010 61601

LinkedIn :

https://www.linkedin.com/in/ba

References for this article

https://www2.deloitte.com/us/en/pages/operations/articles/blockchainsupply- chain-innovation.html

https://www2.deloitte.com/us/en/insights/focus/supply-chain.html

https://hbr.org/2020/05/building-a-transparent-supply-chain

https://www.blumeglobal.com/learning/internet-of-things/

https://www.forbes.com/sites/forbestechcouncil/2021/11/22/introducingblockchain-six-limitations-for-enterprises-to-remember/?sh=70b6d318313f

https://erpnews.com/future-of-supply-chain-reinvention-demanded/

https://www.mckinsey.com/business-functions/operations/ourinsights/blockchain-technology-for-supply-chainsa-must-or-a-maybe