By Mohan Kalaiyappan

Some forerunners of Industry 4.0

Chess-playing computers spurred Samsung engineers, around 1997, to develop internet-enabled Refrigerators that would start thawing the beer in the freezer even before the customer reaches home and Fuzzy-Logic (AI) Washing Machines (of Samsung and Whirlpool) that would “see” level of dirt and “sense” the types of clothes loaded and adjust washing process automatically. Around the same year, in Coimbatore, we came across Taiwanese-made ESTEAM Milling machines communicating their breakdowns to Service Engineers, via internet. In 1990s, we were amused to hear about SDCNC and SDSCCNC (SD — Self-Diagnostic; SC – Self-Correcting) machines.

In 2016, any Mahindra Reva Electric Vehicle getting stranded in Bangalore would be tracked by a Server and Service will be arranged automatically. Hyundai introduced Lean-burn i10 cars (and Maruti Suzuki too) that would automatically and dynamically adjust the fuel setting after sensing the load on axles, external climate, resistance due to road slope, etc.

Industry 4.0 buzzwords

Industry 4.0 is also known as Smart Manufacturing, worldwide. But the Germans prefer to call it Digitalization (of Manufacture). The scientists call it IIoT (Industrial Internet of Things).

Industry 4.0 in Aerospace & Defence

We all know that Drones were extensively used in Afghan to launch missiles, with a near-90% hit ratio. Around early 2017, Pilotless F16 Fighter planes were developed to go in real world combat with F35. Indian aerospace expert VK Saraswat, taking a cue from our epics Mahabharata and Ramayana, asserts that only a Swarm of Drones can be successful in future combat because a single, large drone can be easily brought down by the enemy. May be, a group of drones can distract the enemy while another group does the job, even we can afford to lose a few of the group in the process. The entire swarm will function as some microbes which are so perfect in coordination that they are akin to a single organism! He calls these advancements Aerospace 4.0. Not to be outdone, L&T is developing a fleet of (small) fast attack marine crafts.

Indian Army experts are already working on AI-enabled “Loitering Munitions” which can hover around a target and study it before deciding — on their own — to attack or return to base. The USA has been working on Theatre Warfare for long. In this, the Situational (Location) Awareness helps the military to extract the maximum damage to enemy, with minimal assets and casualties on one’s own side, eliminating all friendly-fire. Now AI is getting blended in these ambitious goals.

Bio mimicry (Bio Inspired Designs & Systems)

The earliest known example is Dupont Nomex Honeycomb Aerospace panels (of 1970s) inspired by the humble honeybees. At NAL, Bangalore, Shape Memory Alloys are now used in Wing-Tip warping drones sans hinges for flaps/rudders, mimicking birds. Ferromagnetic Shape Memory alloys (also known as Smart Materials) are now employed in LCA (Light Combat Aircraft) in the Shrink-Fit Hoop (sealing) Rings of Fluid Connectors. Developed by the Foundry & Forge Division of HAL, this works on the basis of Martensitic Transformations.

3D Printing (Additive Layer Manufacturing, ALM)

In 1990s, we read in disbelief when a science journal reported that 3D objects can be “faxed”. In Airbus Industrie, that is what is precisely happening now. The supplier of plastic and metallic parts for Prototype Aircrafts e-mails the CAD file in STL / DXF formats and they are printed at Airbus factories in France and Germany for assembly. What a saving of transportation costs!

Lattice Structures, Topology Optimization are all used in ALTAIR software to create near-perfect — as in nature — extremely high Strength-to-Weight ratio (Lightweighting) parts hitherto impossible even in advanced FEA. This is also Bio mimicry. GE became the first company to mass produce Burner nozzles for LEAP Jet Engines, by 3D Printing. Airbus successfully flew Liebherr-Aerospace’s 3D printed spoiler actuator valve block (a Hydraulic, Primary Flight Control module, made of Ti Powder) on a flight test Airbus A380, on March 30, 2017, breaking the myth that 3D-Printing is unreliable for critical, porosity-prone parts.

Aspiring engineers can try DFAM (Design For Additive Manufacturing) as career progression.

Health Monitoring

LCA (Light Combat Aircraft) employs the indigenously developed IVHM (Integrated Vehicle Health Monitoring) system comprising a network of embedded sensors, transponders and others to communicate to ground the health of the aircraft in flight. FBG (Fiber Bragg Grating) is an Optical Fiber based sensor system that can capture multiple parameters like strain, temperature, displacement using a single sensor developed jointly in India by IISc and Southern Electronics, Bangalore. Predictive Analytics, Condition Monitoring, Reliability Centered Maintenance, Fault Diagnosis, BIT (Built-In-Test), Testability, Reliability Engineering, Six Sigma are all related concepts.

Industry 4.0 Enablers

Industry 4.0 is possible only if we come out of our mindset (and comfort zone?) and embrace a totally IT-driven business based on Data-driven decisions. The old-fashioned manual supervisions should give way to QMS-integrated ERP systems and even the modern AutoCAD (parametric-modeled) drawings should be reinforced by Mathematical modeling of Products (and Services). Regression is one simple way to understand Mathematical modeling. Regression can be at the micro-level such as Predicting Aircraft Fuselage Joint Fatigue Life (Stress Concentration Factor) based on various design parameters like Rivet Pitch, Sheet Thickness, Lap Joint, Width, etc., (given below as y = f(x)) :

y = 2.019 – 0.0383 x1 + 0.0491 x2 – 0.096 x3 + 0.000154 x1*x1 – 0.000176 x2*x2

– 0.00018 x3*x3 – 0.000146 x1*x2 + 0.00238 x1*x3 – 0.00092 x2*x3

+ 0.000033 x3*x3*x3 – 0.000081 x1*x3*x3 + 0.000070 x2*x3*x3

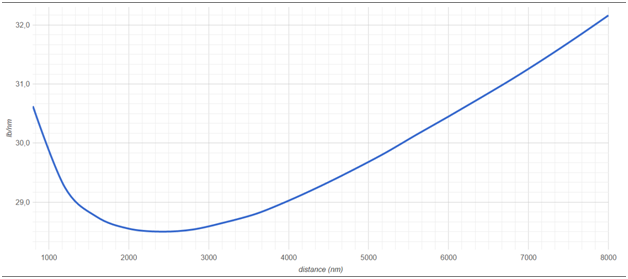

or at Macro level like key Business Success Factors such as Aircraft Range vs Fuel Load per Nautical Mile

Regression Benchmarking is used for successful Reverse Engineering, a technique used in hard-to-get A &D Spare Parts development. To become a supplier to Boeing a company must embrace DPD (Digital Product Definition). Even many expert Indian suppliers get dropped on this alone. Virtual Prototyping (VP), Virtual Testing (VT), Virtual Process Planning (VPP) and Digital Twin are all prevalent overseas and in few Indian enterprises. Gone are the days that these advanced techniques were seen as unreliable. They are now as trustworthy as real life scenarios.

AI (Artificial Intelligence), AR (Augmented Reality), VR (Virtual Reality), XR (Crossed Reality) or MR (Mixed Reality) are used in, for example, training a Submarine Maintenance Technician without even he or she leaving the ground. Fighter Aircraft Pilot Training Simulators are all incorporating these technologies. Lufthansa Technik, a leading MRO (Maintenance Repair Overhaul) Services provider for commercial aircrafts employs these techniques. Radiant Coral Digital Tech, Bangalore makes Training Simulators for Boeing 737 Pilots.

Airbus aircrafts are sending many Terabytes of data every minute to the ground servers for analysis later. Ramco India is one such MRO Data Analytics company drafted by Airbus. One interesting application of Data Analytics is for Air Crash avoidance by finding and linking what were all the vital parameters like Engine RPM, Engine Turbine Rear Stage Temperature, Vibration, Altitude, Attitude just few seconds before crash and finding if there is a Correlation (Regression) though we don’t know the real root causes at the moment due to lack of 360 degree grasp of the FTA (Fault Tree Analysis) or Physics Of Failure (POF).

Artificial Intelligence (AI)

In this, the USA ranks No.1, China No.2 and India No.15. We were the IT Capital of the world for nearly 35 years and so we should close the gap by strategically networking nodal research institutes like ISI, IITs, IISc, CR Rao Advanced Institute of Mathematics, Statistics and Computer Science and other overseas partners like Intel Nervana , MATLAB Simulink, NVIDIA, IEEE, SAE and SRL (Stanford Research Lab). ANN (Artificial Neural Network), CNN (Convoluted Neural Network), DNN (Deep Neural Network) are related techniques.

Autonomous Driving & Flight

In 2012, CVRDE have successfully developed Remote-controlled Tanks with 1km Control Radius based on PoC (Proof of Concept) of a Honda CRV SUV fitted with Festo Actuators and NI-LabVIEW systems. These examples coupled with the vast pool of IT-qualified youth with fertile imagination hold promise for India regaining its global ranking of AI. IISc have conducted Autonomous Drone contests. Anna University Aerospace Department has won the International Medical Challenge drone contest at Australia.

A & D Industry 4.0 Prospects

LMW, L&T, ELGI, Roots Industries, G-Plast, Ramm Precision, Venkateshwara Industries, Lucas TVS, Polyhose, Alpha Tocal, Dynamatic Technologies, Maini, Sika, CYIENT, Aques, Quest, Axis Cades, Mahindra Aerospace, Tata Advanced Systems, Tata Advanced Materials, Kalyani, Godrej Aerospace, AvioHelitronics, etc., have the potential to grow by adopting Industry 4.0. LMW are producing the much-needed Carbon Composite Tubes and Sheets which are the Raw Material for building some products like drones. Coimbatore is a Lean & Agile New Product Development model hub and a national VA VE / TRIZ Benchmark.

Reliability Engineering

HBM Prenscia nCode, Siemens LMS can predict life of a product by simulation-loading the stressors through the required number of cycles (e-g: 1 million) onto the meshed 3D-model. CFR (Center For Reliability, Taramani), ISI & IIT-Kanpur, ASQ, USA, IEEE impart this knowledge.

The Author is a Production Engineering graduate from NIT, Trichy with 38 years of expertise. He has worked on R&D of Air (WABCO) & Hydraulic Brakes, Disc Brakes, Clutches (Maruti Suzuki), Supply Chain Management, Reverse Engineering of Steel Plant parts (Vizag Steel), Quality Management Systems at G-Plast & Janatics. Was Principal Consultant at TCS Global Sourcing Department, Project Manager for Daimler India Heavy Duty Truck Prototype build and SME (Subject Matter Expert) for Indian Offset Partner (Axis Cades Aerospace) of Thales for the IAF Mirage 2000 Fleet Midlife Upgrade Project. He is an ISI Certified Six Sigma Black Belt and an ASQ Certified Reliability Engineer. He is a classic member of SAE and a Life member of Aeronautical Society of India. His interests include AR, Drones and 3D Printing