3 MANUFACTURING MANAGEMENT LIES YOU PROBABLY BELIEVE AND WHY THE TRUTH MATTERS

“After having worked with manufacturing leaders in over 30 countries, I can tell you that there are probably 3 main manufacturing management lies that you believe, and it’s causing you to not only be less effective, but also causing you to be more stressed than you need to be.

Manufacturing is hard, but it’s a lot harder when management believes the lies I uncover in this short document.”

Saturday morning. 3am. I’m there as a leader, on the shop floor, standing on the production line whilst my night shift team try to get the equipment running.

Saturday morning. 3am. I’m there as a leader, on the shop floor, standing on the production line whilst my night shift team try to get the equipment running.

After a recent product changeover, we were dealing with a problem – you know the kind. The kind that could take one hour to fix or six hours to fix.

I couldn’t help but think, “am I really helping here?”.

The answer to that question was, and is “not really”.

On another occasion, I was a manufacturing consultant, hired by the CEO because the factory had become a bottleneck for growth. Production results were poor, there had been several quality issues in the market and the team needed help.

The Operations Manager guided me towards the production floor and, pointing out the Line Managers, the Maintenance Manager, the Project Engineer, all sitting in their offices, proceeded to call them “desk jockeys”.

I could see him digging his nails deeper into his palm, his fist clenched. He obviously felt annoyed that they were not on the factory floor, doing what he thought they should do – oversee everything

When the tour was complete I had a chance to talk to the CEO alone about this.

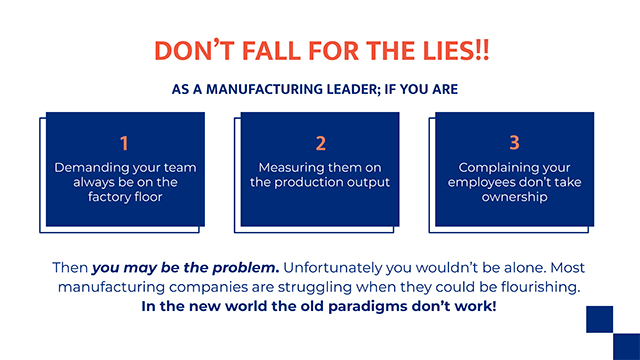

He agreed with the Operations Manager. He felt the main issue was that the managers did not spend enough time on the production lines firefighting. No wonder they had poor results!

The truth is that when I was a manufacturing leader, I was out on the production floor because I thought I should be. I knew it was expected by my boss and I didn’t want to look bad in his eyes. I wasn’t really helping.

In fact it was worse than that. When I was on the lines I took the ownership, accountability and decision making opportunity away from the team.

I was simply a highly paid obstacle to the teams’ growth.

I was simply a highly paid obstacle to the teams’ growth.

It’s a common misconception that ‘leaders should be on the factory floor’. In manufacturing, the problems often show up in production but that is because it’s where many other inputs end up. It’s the variability in the input processes that cause the majority of problems in production.

The issue in my client’s factory was not that the leaders were in their offices, sitting behind their desks. The issue was that they weren’t proactively finding, and systematically eliminating, the causes of the recurring problems.

On hearing my assessment, this CEO was sceptical. Although he understood the concept of what I was saying, and it seemed to make sense, he didn’t feel his team would ‘get it’. In his mind they didn’t have the capability or incentive to change. They had “had it too easy for too long”.

On hearing my assessment, this CEO was sceptical. Although he understood the concept of what I was saying, and it seemed to make sense, he didn’t feel his team would ‘get it’. In his mind they didn’t have the capability or incentive to change. They had “had it too easy for too long”.

So I suggested we started small in order to validate what I was saying.

First we started with one line in a factory of 8 lines, and as I predicted, results rapidly improved.

So then we did the whole factory, then, eventually all 4 factories. Over a period of three years, through our consulting, the entire manufacturing culture shifted along with the results. Individuals were focused on their area of expertise to proactively eliminate the priority issues that were holding the business back.

It was because of this that the business doubled in revenue and a few years later was sold to a competitor for a whopping $520 million.

I’m still in touch with the managers who led that transformation. They are stars in the new organisation, applying many of the practices we put in place together in the wider business.

When John F Kennedy set the goal of landing a human on the moon it was clearly a massive challenge with a lot of inputs and variability.

When John F Kennedy set the goal of landing a human on the moon it was clearly a massive challenge with a lot of inputs and variability.

The output was reaching the moon. What they didn’t do was stick a person in a rocket and fire him into space to see how far he would get, then tweak the rocket design and try again, getting an extra 1000 miles each time until they made it.

The ‘push the start button and pray’ approach was thankfully not an option.

What they did was analyse all of the inputs and reduce the variability in each until the combined variability gave them the required probability of success. The key performance indicators (KPI) were the in-process measures, the inputs that could be improved.

By focusing on the right KPI and the ideal ‘operating strategy’ for their business, they achieved the consistency necessary to achieve something many people said was impossible.

I know a way to significantly increase the output of any production line in 5 MINUTES. First, you turn off the quality sensors (or put masking tape over them). Second, you increase the speed. Third, you pray.

If this sounds ridiculous I would suggest you have not worked in many manufacturing facilities. I’ve seen more than 200 factories in over 30 countries and I can tell you that the “Push the start button and pray” approach is alive and well.

If this sounds ridiculous I would suggest you have not worked in many manufacturing facilities. I’ve seen more than 200 factories in over 30 countries and I can tell you that the “Push the start button and pray” approach is alive and well.

Why would this be the case? Well, when you’re under pressure to increase the production volume, and that is how you are measured, you find creative ways to increase the volume.

● “But won’t this risk having more quality defects?”. Yes of course, but you probably won’t know that until later.

● “But won’t this risk having more production equipment failures?”. Yes of course, but you probably won’t know that until later.

● “But won’t this create more scrap?”. Yes of course …

Fortunately, or unfortunately, we get what we measure. The fact is that production volume is an output. It’s a culmination of many inputs like people, materials, machines and methods.

My wife noticed my change in behaviour. A social media post had accused my client’s products of being unsafe and, as negative news spreads 5 times faster than positive news, it wasn’t long before the TV had picked up the story. Sales were already starting to drop.

My wife noticed my change in behaviour. A social media post had accused my client’s products of being unsafe and, as negative news spreads 5 times faster than positive news, it wasn’t long before the TV had picked up the story. Sales were already starting to drop.

I had gone quiet, which was unusual for me at family dinner time.

I’m a huge advocate for producing only high quality products and I recognise injustice when I see it. These products were safe and there was a targeted agenda against my client. I was deep in thought formulating a response.

What my wife questioned was why this issue affected me so much.

Why was I feeling such ownership for this issue?

My direct responsibility to my client had nothing to do with product safety. I was not accountable for sales, the loss of profits or the reputation of the business. I was there to improve production. As my wife pointed out, this was not my problem.

As I pondered her questions, I realised that during my 17 years with my previous company, P&G, I had always been called an ‘owner’. An equipment owner, an area owner, a line owner, a regional owner.

Even though I didn’t actually own any of these things, I had gradually felt and acted like an owner. From day one I was given responsibility, accountability and decision making authority. I was allowed to influence the direction of ‘my area’ and my opinion counted. P&G built my ownership muscle through repetition.

As a consultant, my ownership behaviour reflected onto the work I did with my clients. I couldn’t help it. I had been trained to take responsibility, to own the results. My wife, of course, recognised these behaviours and helped me formulate the interviews I would do for TV.

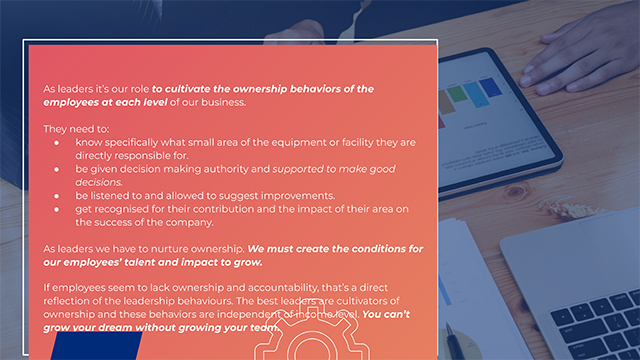

If employees seem to lack ownership and accountability, that’s a direct reflection of the leadership behaviours.

The best leaders are cultivators of ownership and these behaviors are independent of income level. You can’t grow your dream without growing your team.

Having talked to thousands of frontline employees, I’ve realised that they are heavily dependent on the success of the company. It’s not easy as a frontline employee to find another job that pays well and without their job their family can be devastated.

Many frontline employees have come from hard working families and are motivated to improve the prospects for their children. They want to take ownership in their roles so that they can influence the success of the business and protect their families.

To get different results you need a different approach.

You need to be brave enough to challenge the old lies and replace them with practices from the best.

Having been blessed to work with manufacturing leaders in over 200 companies across 30 countries, I noticed that in these new times we need a new approach.

If developing a world-class leadership team for your manufacturing business is important to you, check out the link below.

http://www.linkedin.com/in/kevinsnook/

About the Author:

Fractional Manufacturing Director | CEO – Saxagon Ltd.

With over 30 years of experience, I have helped 200+ midsize manufacturing companies across 30 countries achieve significant improvements in efficiency, cost savings, and overall performance. My proven strategies deliver concrete results without the costly trial-and-error process.

Why Choose Me?

It starts with a conversation. I’d like to understand more about your situation and see if it makes sense to explore further. If it does, we will sign an NDA to keep your business confidential and then diagnose the issues in depth. This clarity allows me to determine if I can help, and you to decide if you want my assistance.

I have a 100% record of fulfilling promises to clients. Let’s start with a conversation

Case Studies To Ask About:

• Division A – $3 million annualised in scrap reduction.

• Division B – $1.2 million in capital avoidance working with equipment supplier

• Division C – Supported 3x sales growth through efficiency and layout design of new factory

• Division D – Built manufacturing team capability as key driver in business sale for $520 million

• Division E – $600k annualised scrap savings and $200k cost avoidance on new line start-up

• Division F – $900k annualised scrap savings

• Division G – $4 million cost avoidance on new line through efficiency improvements

• Division H – $4.2 million cost savings through run-to-target strategy

• Division I – $600k in Maintenance and Repair (M&R) cost savings

• Division J – Rescued $12 million contract with customer through quality improvement

• Division K – $1.8 million in cost avoidance (new machine) through efficiency improvement

• Division L – $1.2 million annualised cost savings through scrap reduction

Do you have any questions? you can contact Mr. Kevin

E-mail | Website | FaceBook | YouTube | Blog